Annular neodymium iron boron grinding tool

A technology of NdFeB and tooling, applied in the direction of grinding workpiece supports, grinding machines, manufacturing tools, etc., can solve the problems of inconvenient installation and removal of ring-shaped NdFeB, troublesome positioning and installation of ring-shaped NdFeB, complex structure, etc., to achieve Simple structure, high grinding efficiency, easy installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

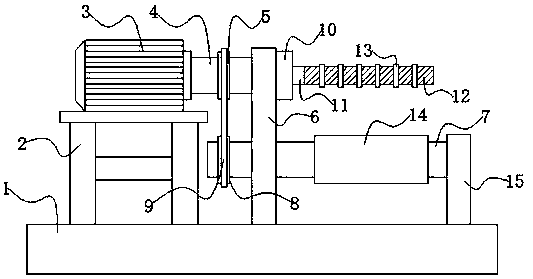

[0011] Such as figure 1 As shown, the invention discloses a ring-shaped NdFeB grinding tool, including a base 1 and a channel steel bracket 2. The left side of the base 1 is fixedly installed with a channel steel bracket 2, and on the channel steel bracket 2 A rotating motor 3 is installed, the shaft end of the rotating motor 3 is fixedly connected with a main shaft 4, and a driving pulley 5 is fixedly sleeved on the main shaft 4, and a sub-shaft arranged parallel to each other is arranged below the main shaft 4 7. The left shaft end of the auxiliary shaft 7 is fixedly sleeved with a driven pulley 8, the driving pulley 5 is connected to the driven pulley 8 through a transmission belt 9, and the right shaft of the main shaft 4 The end is connected to the installation rod 11 through the reducing wheel 10, the right end of the installation rod 11 is a threaded end 12, and a plurality of threaded locking blocks 13 are threadedly mounted on the threaded end 12.

[0012] A frosted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com