Blowing needle base mechanism for blow molding die

A blowing needle seat and blowing mold technology, which is applied in the field of blowing needles for blow molding, can solve the problems of large overall volume, high preparation cost, and increase the volume and weight of the blowing needle seat, so as to ensure the stability of use and reduce production. Cost, effect of reducing machining accuracy and assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

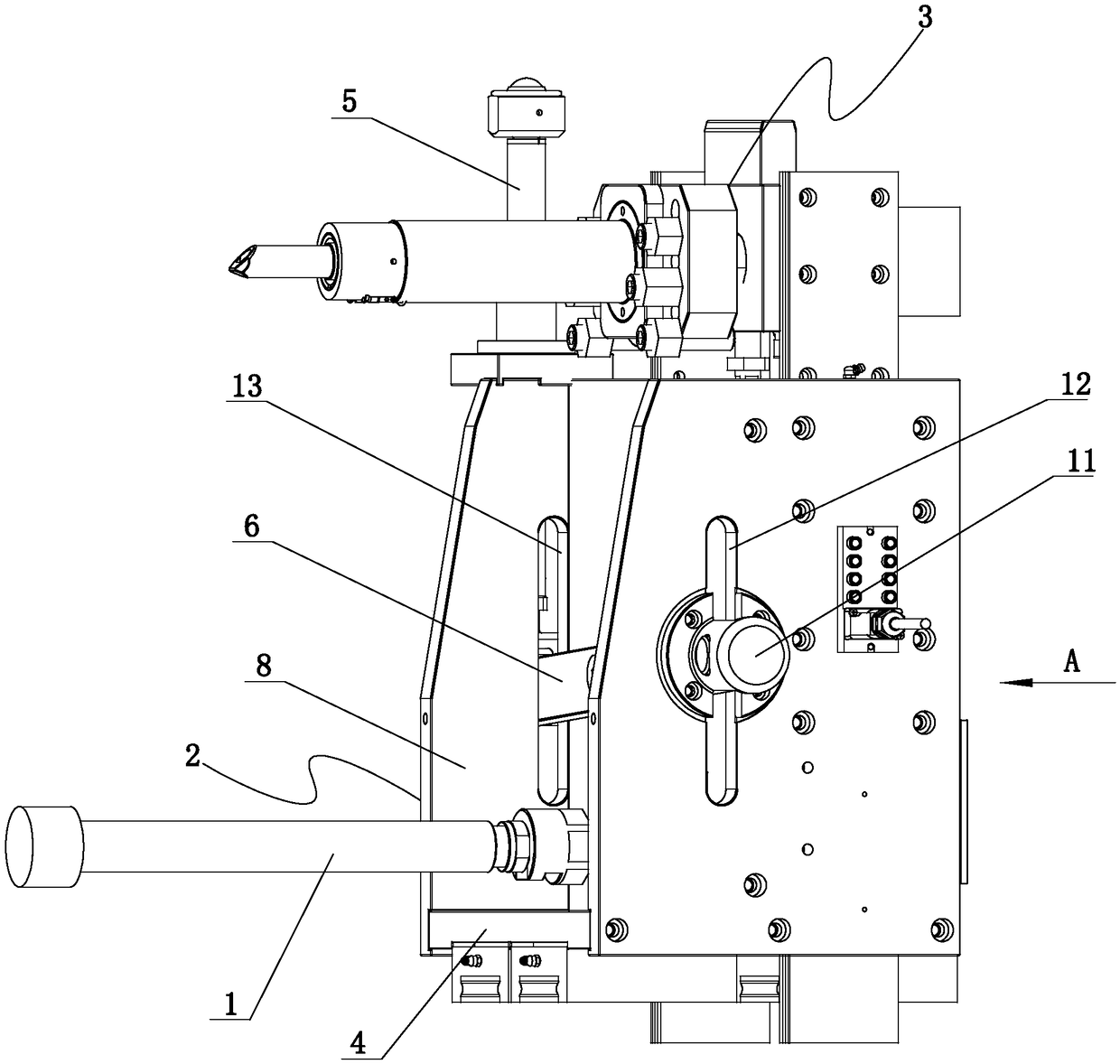

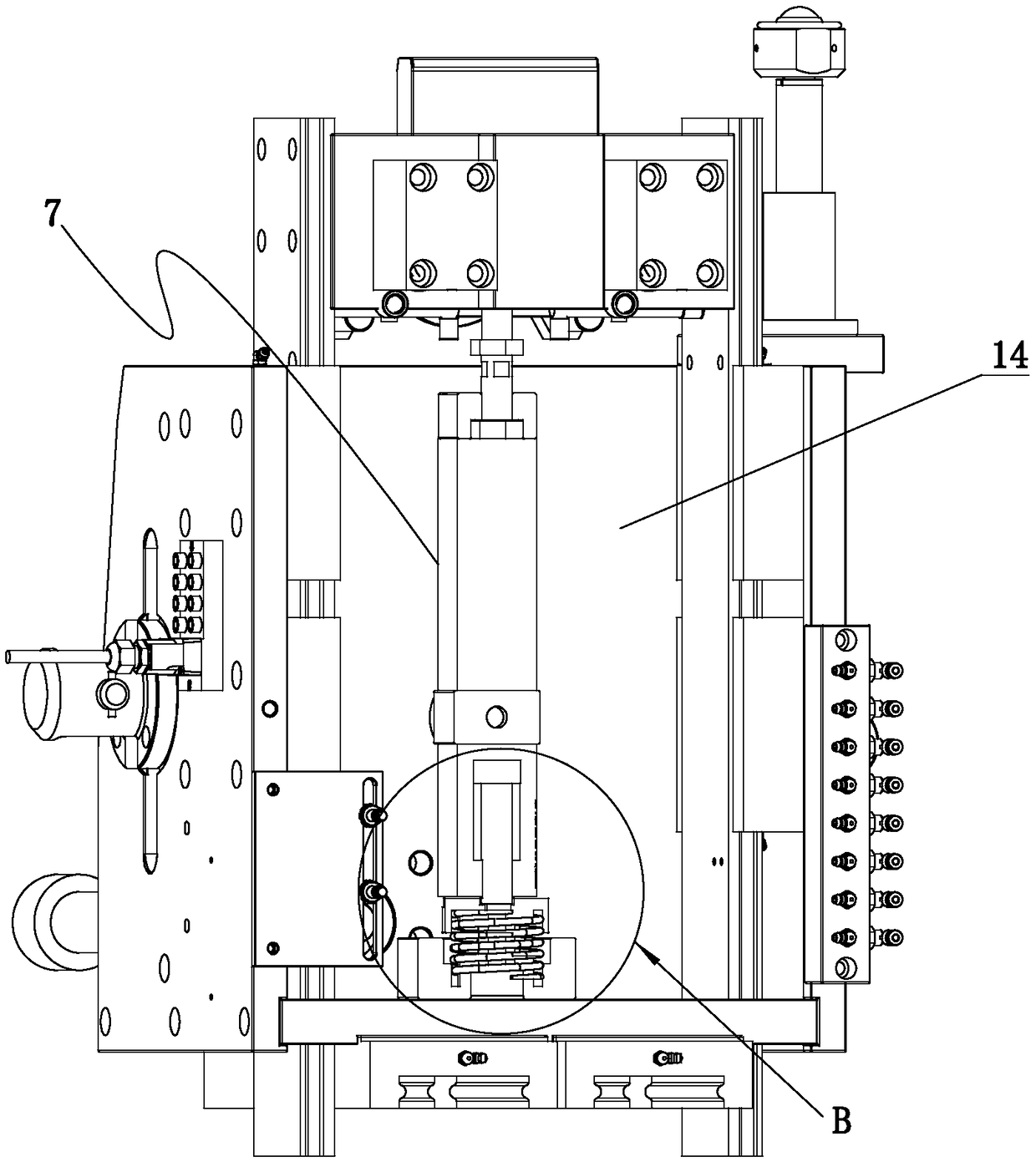

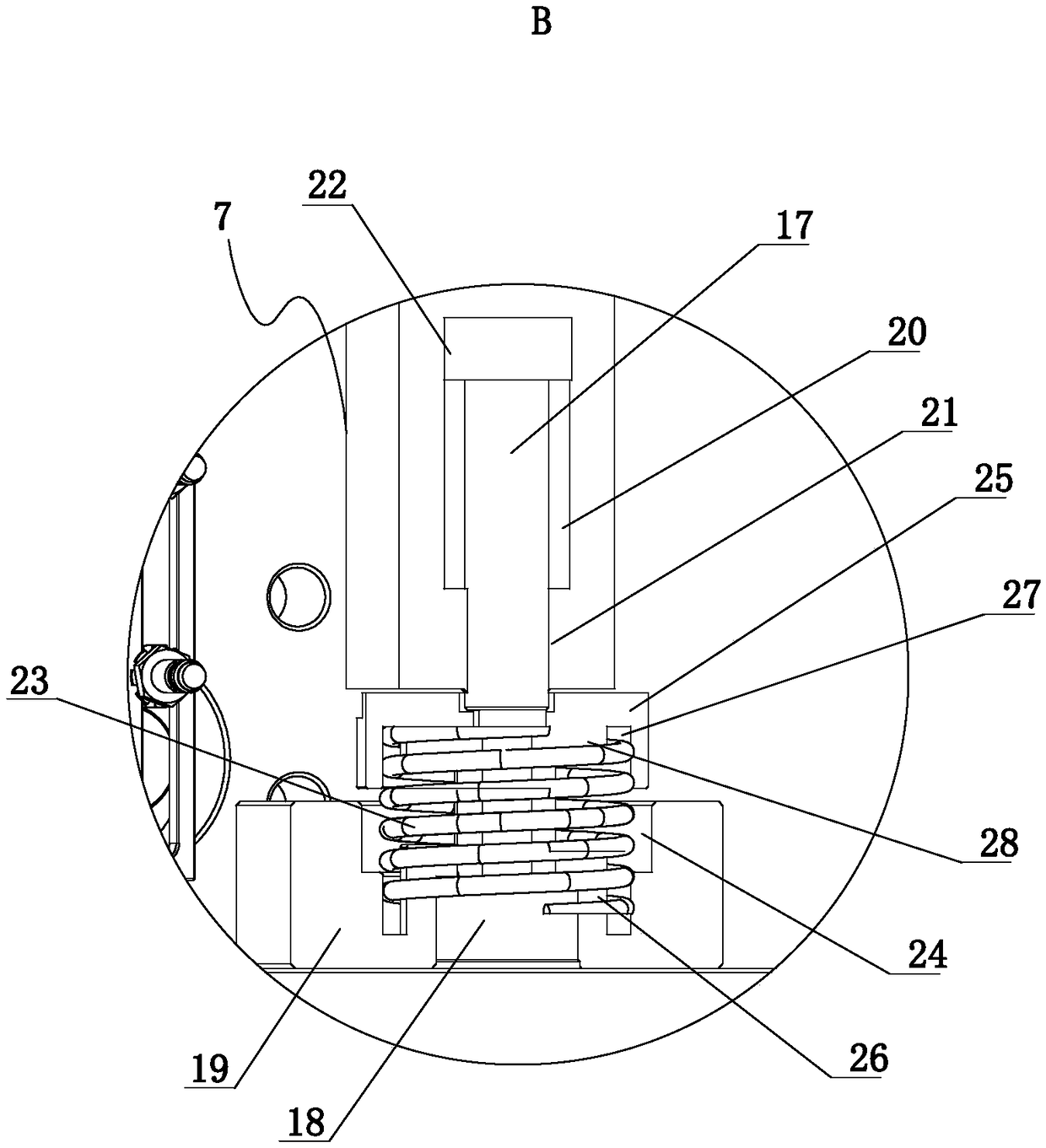

[0027] combine Figure 1-8 , a blowing needle seat mechanism for blow molding, which includes a lifting cylinder 1 fixed on the mold frame, a blowing needle seat 2 slidably connected to the mold frame, and a blowing needle 3 movably connected to the blowing needle seat 2 (of course It also includes other parts, but because it does not involve the invention of the present invention, so it will not be repeated here), one end of the lifting cylinder 1 is connected with the blowing needle seat 2 through the transverse partition 14, and the other end of the lifting cylinder 1 is connected to the mold frame connection, the lifting cylinder 1 controls the overall rise and fall of the blowing needle base 2, and the blowing needle base 2 includes a vertical back plate 4, a push-pull cylinder 5, a connecting rod 6, a push rod 7 and two parallel vertical side plates 8 , the vertical backboard 4 is located between two parallel vertical sideboards 8, and the two sides of the vertical backb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com