Continuous filling and rapid canning system for powder materials

A material and fast technology, applied in the field of canned product processing, can solve the problems of inaccurate filling volume and long filling cycle, and achieve the effects of improving efficiency, facilitating manufacturing and processing, and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

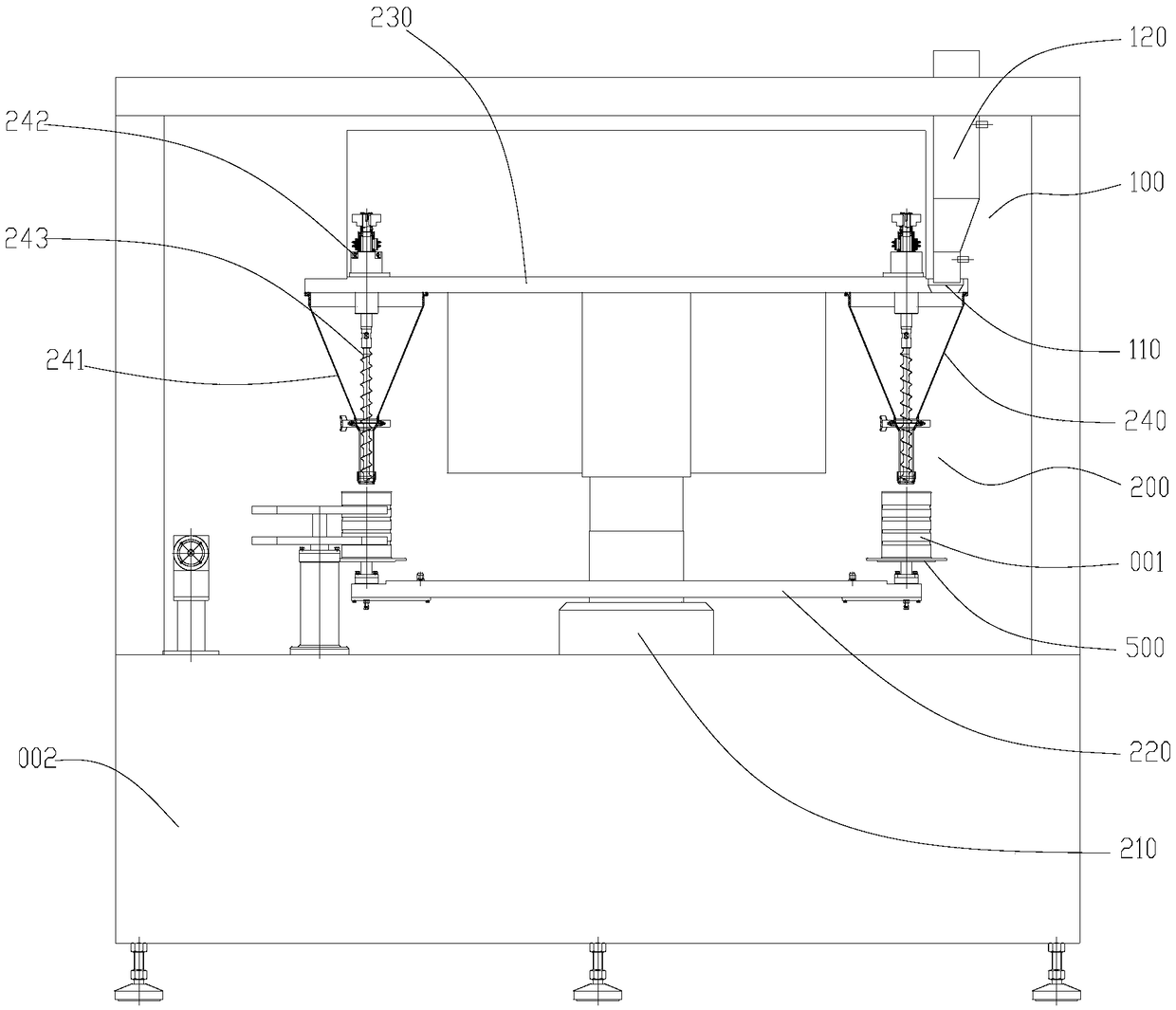

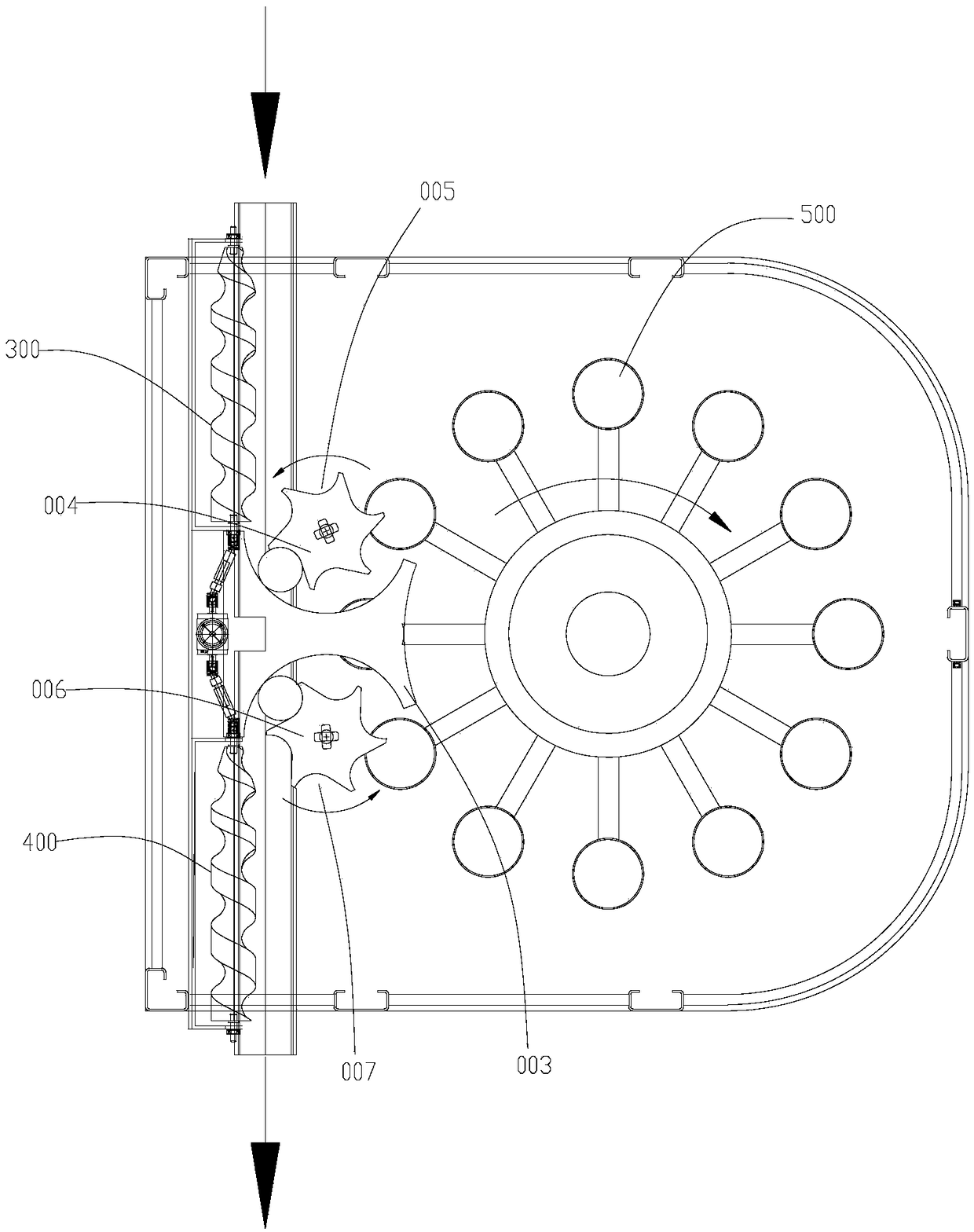

[0037] see figure 1 - Figure 4 , this embodiment provides a powder material continuous filling fast filling system, which can be applied to filling milk powder in iron cans.

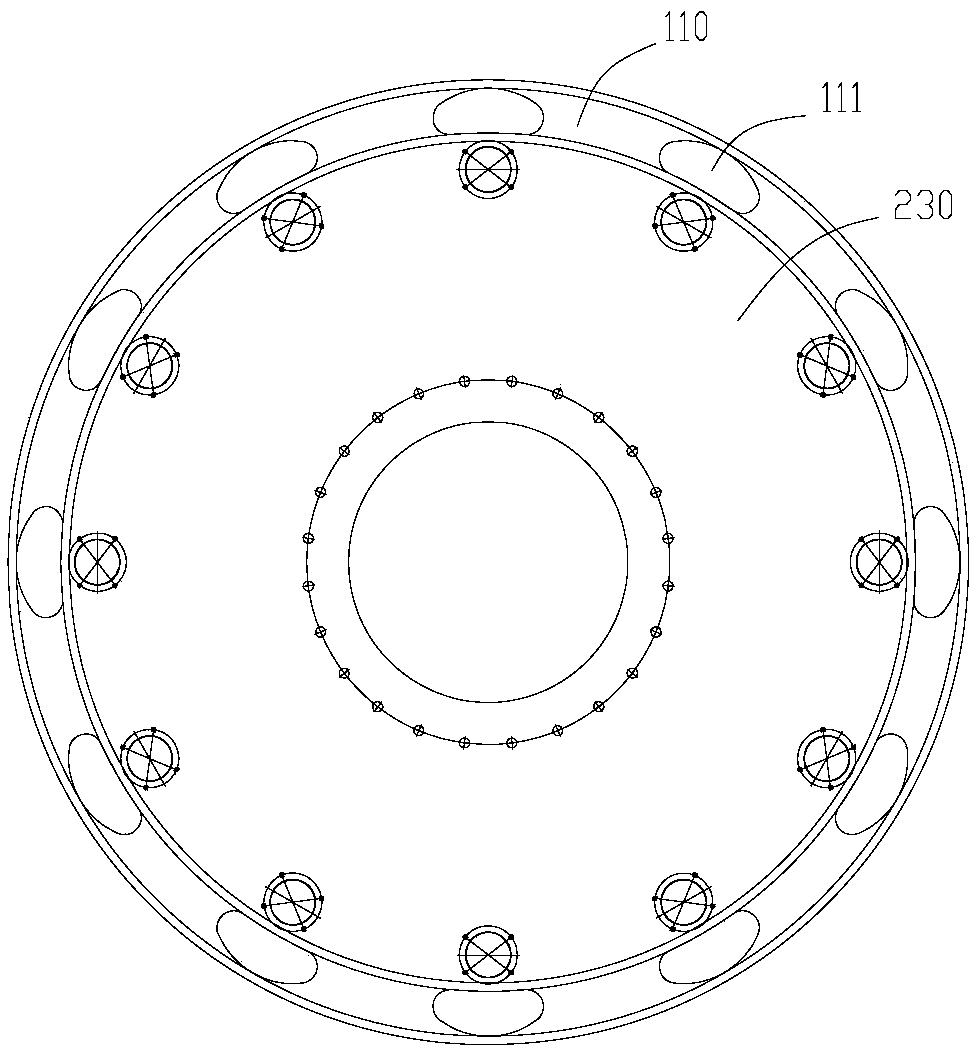

[0038] The powder material continuous filling fast filling system provided in this embodiment includes a frame 002, a feeding unit 100, a rotary filling unit 200, a tank input unit 300 and a tank output unit 400, and the feeding unit 100 includes an annular feeding tank 110 And the feed pipe 120, at least two feed ports 111 are arranged in the annular feed trough 110, and one end of the feed pipe 120 stretches into the annular feed trough 110; the rotary filling unit 200 includes a driving member 210, a rotating base 220, The rotating disk 230 and the filling assembly 240, the driving member 210 is installed on the frame 002, the rotating base 220 and the rotating disk 230 are installed on the driving member 210, the rotating base 220 and the rotating disk 230 are arranged at intervals, and the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com