Bidirectional cushioning piston

A two-way buffer and piston technology, applied in the field of mechanical parts design, can solve problems such as the inability to meet buffer requirements, and achieve the effects of reducing impact, avoiding dynamic unbalanced force, and fast starting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

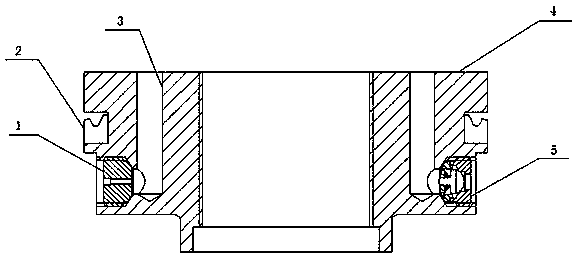

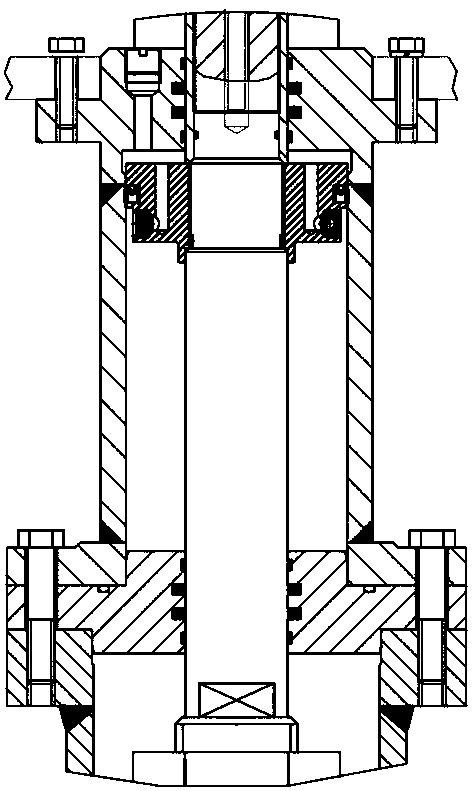

[0025] A two-way buffer piston, including a piston body 4; two fluid passages 3 are arranged in the piston body 4, a throttling plug 1 is arranged in one of the fluid passages, and a check valve is arranged in the other fluid passage 5; A U-shaped seal 2 is provided on the outside of the piston body 4 .

[0026] The fluid passage 3 is "L" shaped, one end of the fluid passage 3 passes through the top of the piston body 4, and the other end passes through the side of the piston body 4; the throttle plug 1 and the one-way valve 5 are arranged symmetrically on the 4 sides of the piston body.

[0027] The throttle plug 1 and the one-way valve 5 are respectively embedded in both sides of the piston body 4 .

[0028] The U-shaped seal 2 is embedded on the outside of the piston body 4 .

[0029] How this example works:

[0030] The U-shaped seal 2 is located above the opening of the lower end of the fluid channel 3; the U-shaped seal 2 is arranged around the outer surface of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com