Tubular pile mold bolt disassembling and assembling device

A mold and bolt technology, applied in the field of bolt assembly and disassembly devices, can solve problems such as low efficiency in bolt tightening or disassembly, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

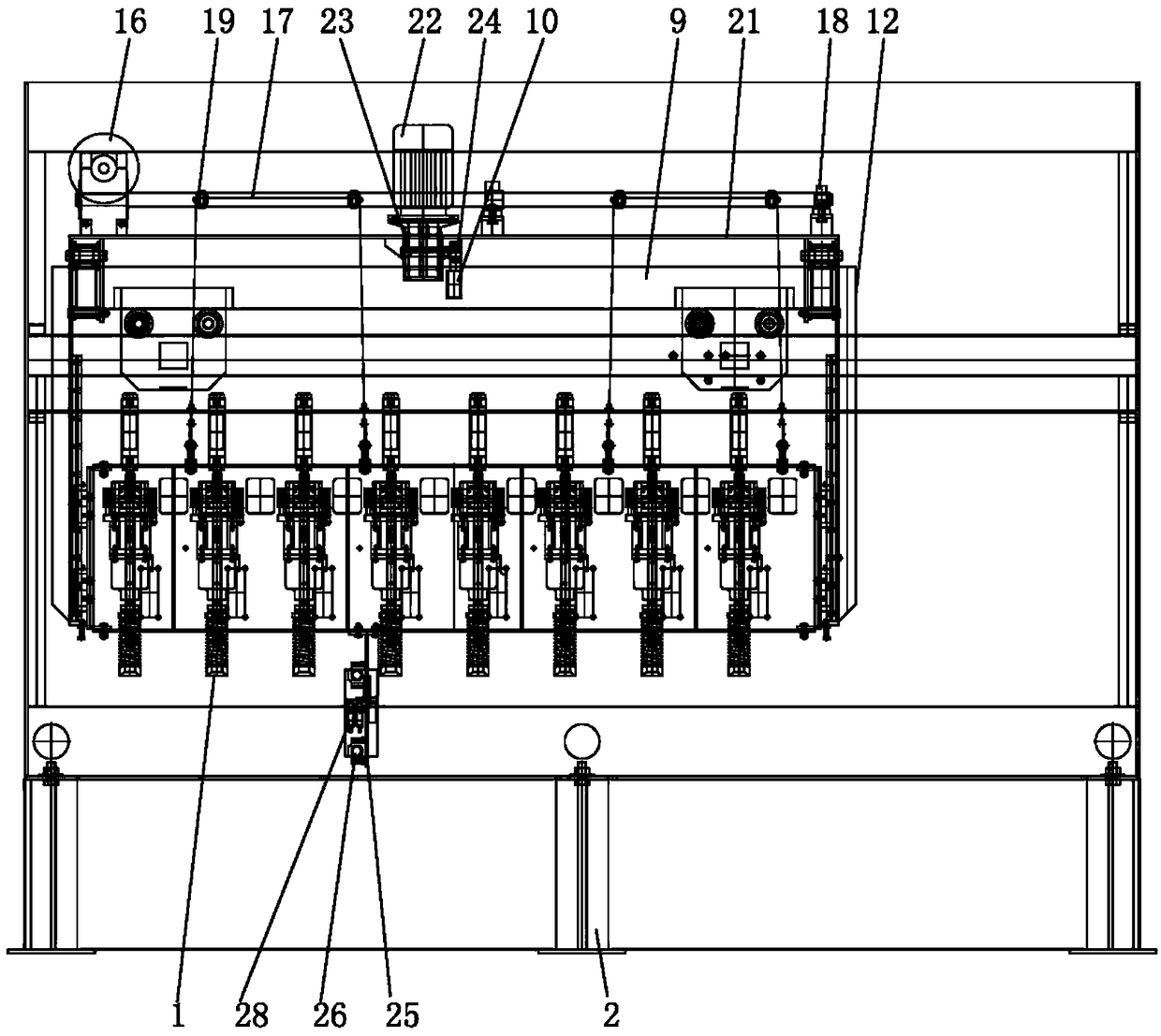

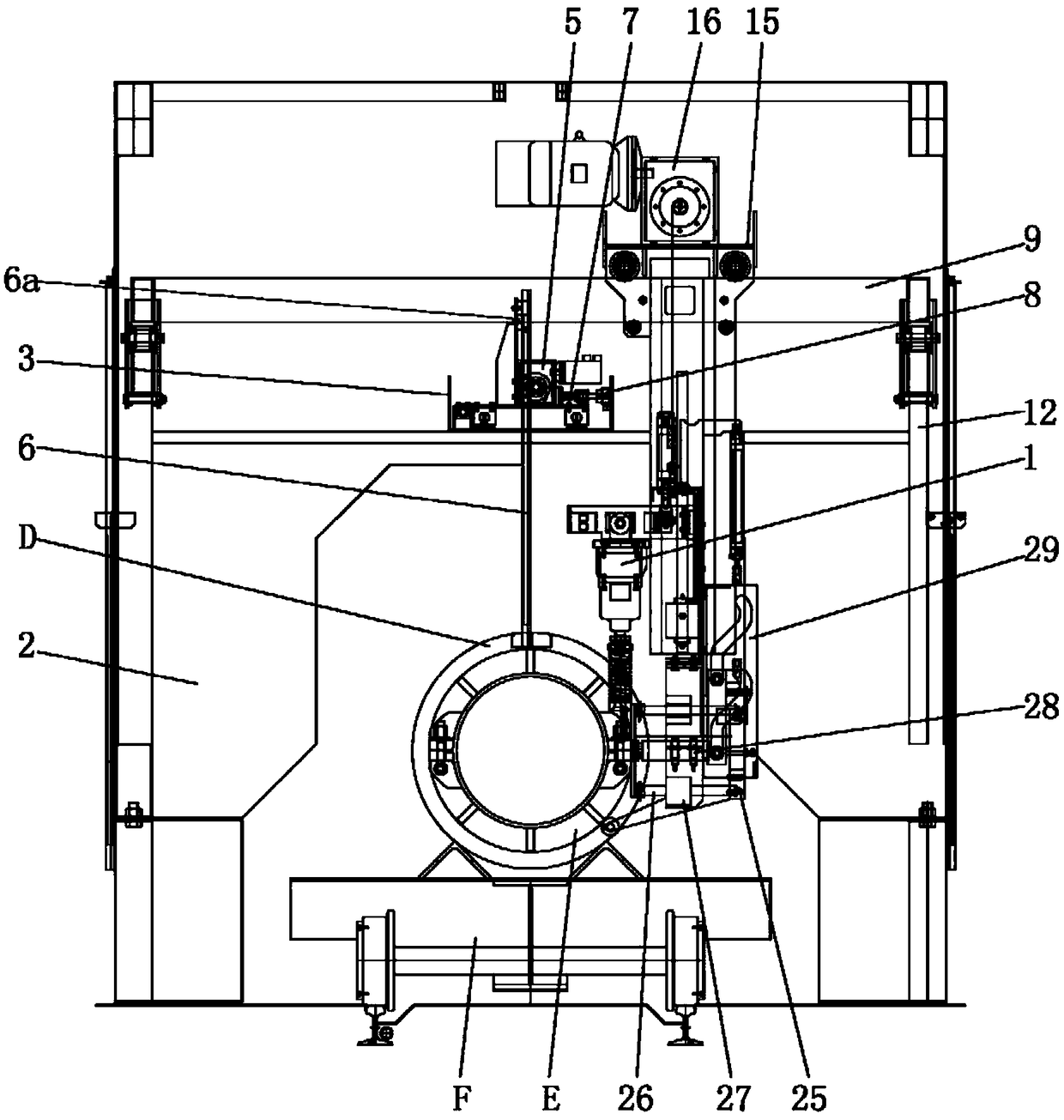

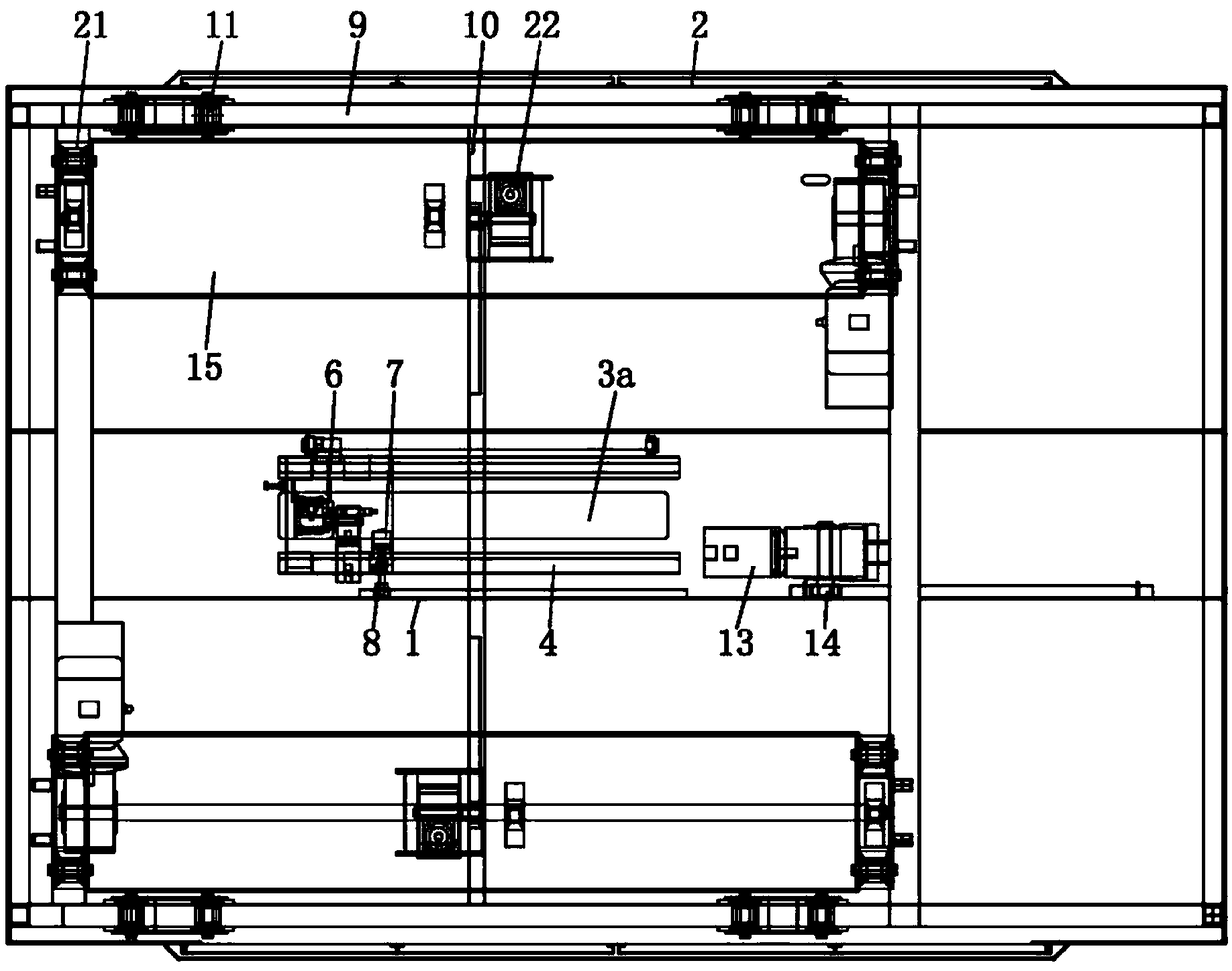

[0026] Such as figure 1 As shown, the bolt mounting and dismounting device for the pipe pile mold of the present invention includes a bolt mounting and dismounting mechanism, a first frame for the pipe pile mold to pass through, a first bracket, and a first lifting device for lifting and lowering along the Y axis of the first frame. Mechanism, displacement detection mechanism, second bracket, second driving mechanism, third bracket, first installation mechanism, third driving mechanism, positioning mechanism, each part and the relationship between them will be described in detail below:

[0027] Such as figure 1 As shown, the bolt assembly and disassembly mechanism 1 can adopt the bolt tightening and dismounting device disclosed in CN207464644U, and can also adopt the wind gun fastening device disclosed in CN104029160A. In this embodiment, the bolt tightening and dismounting device disclosed in CN207464644U is preferred .

[0028] Such as Figure 1 to Figure 4 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com