Material fine-grinding and cutting material platform for intelligent positioning plane fine-grinding machine

An intelligent positioning and fine grinding machine technology, which is applied to the parts of the grinding machine tool, the grinding frame, the grinding bed, etc., can solve the problems of not being able to process multiple parts, not meeting the needs of production, and picking and placing deviations. , to achieve precise positioning and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

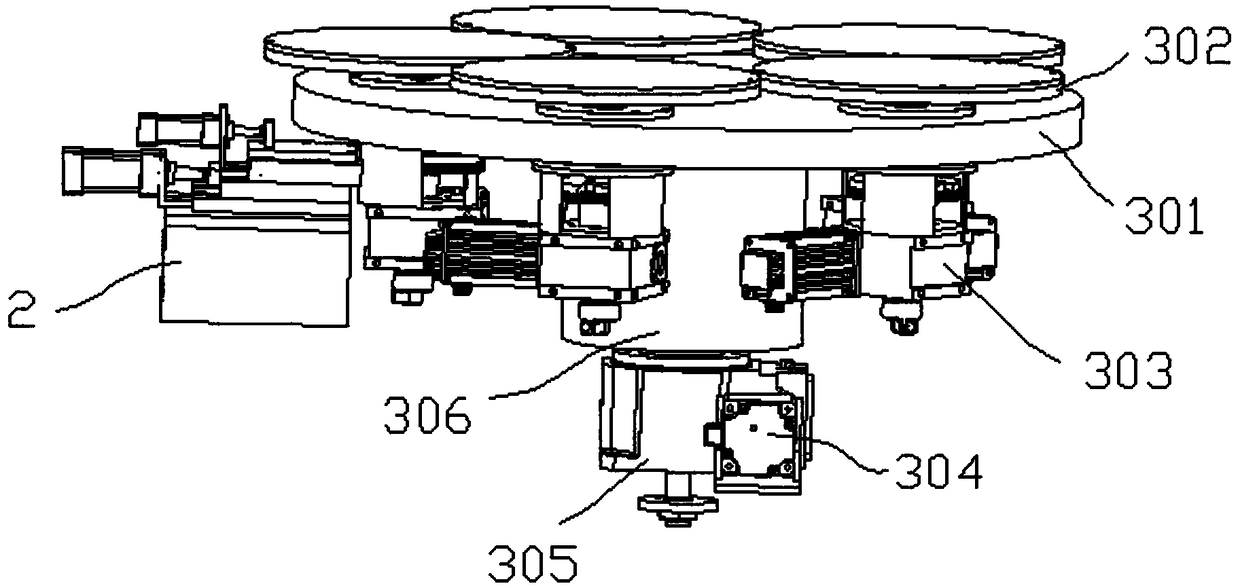

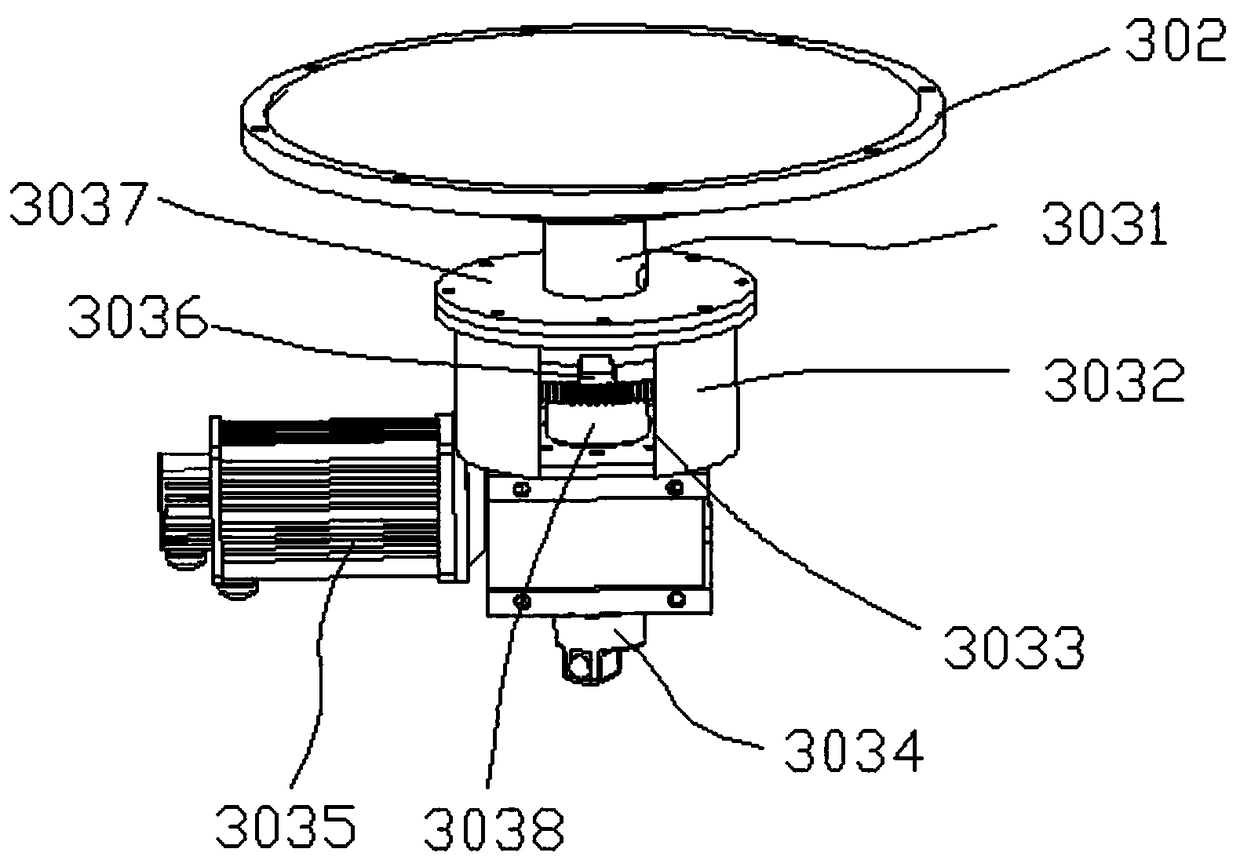

[0019] Such as Figure 1-Figure 5 As shown, the specific structure of the present invention is: it includes a multi-station revolution platform 3 and a dovetail positioning mechanism 2 for precise positioning of the multi-station revolution platform 3 .

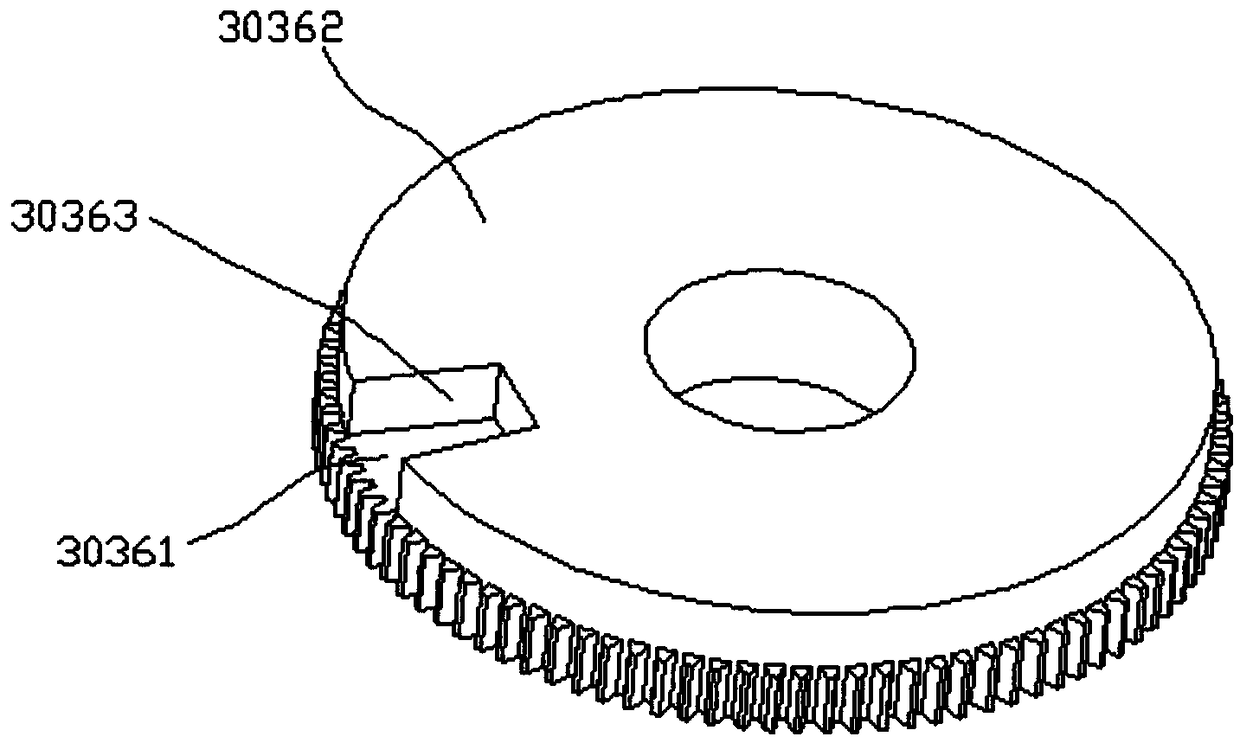

[0020] Preferably, the multi-station revolution platform 3 includes a turntable 301, the bottom of the turntable 301 is provided with a support platform 306, the lower end of the support platform 306 is connected to a multi-station divider 305, and the multi-station divider 305 is connected to a revolution disk drive motor 304 Connection, the turntab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com