A method for manufacturing super-large variable cross-section cable tower steel parts

A production method and variable cross-section technology, applied in wire mesh, architecture, bridge construction, etc., can solve the problems of difficult control of precision, too many joints, and difficult assembly, so as to reduce man-hours, simplify the assembly process, and make the production method simple and efficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

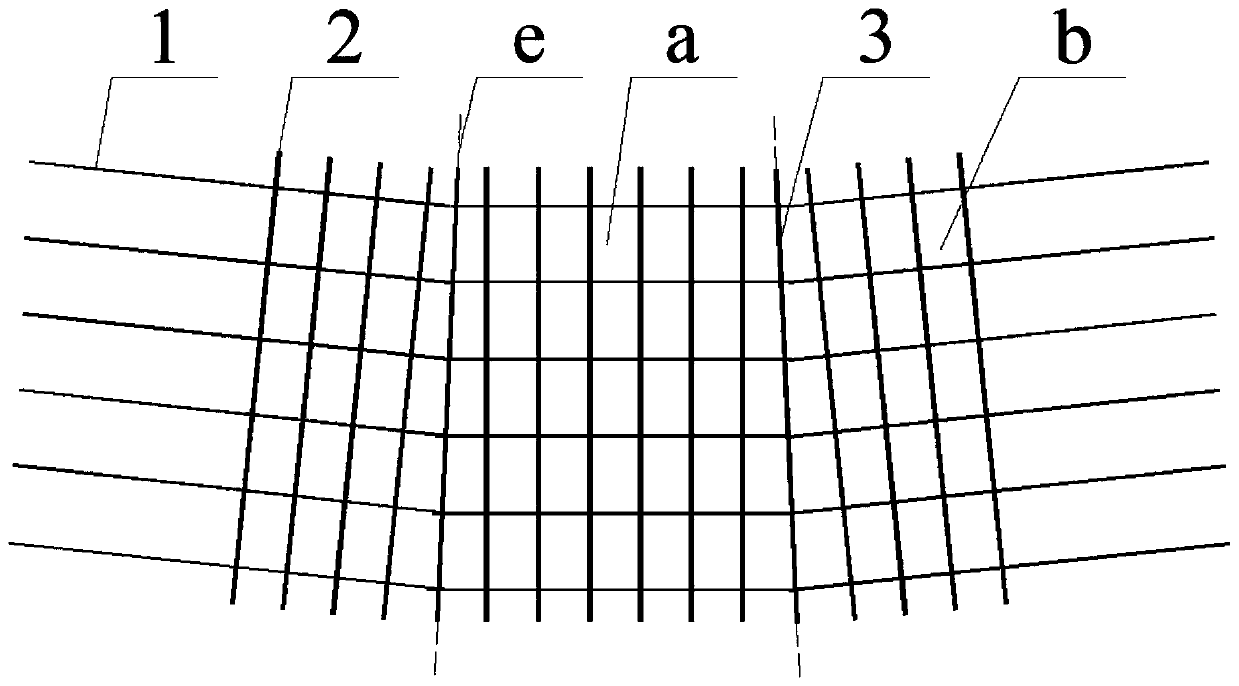

[0043] like Figure 1-11 , the cross-section of the variable-section cable tower of this embodiment is an octagonal structure, and the bottom is large and the top is small. In this embodiment, a half-ring steel mesh sheet is produced by bending twice, and then two half-ring steel mesh sheets are welded together to form a ring-shaped steel mesh sheet, and then the multi-layer ring-shaped steel mesh sheets are bound and fixed together. Form the steel bar parts corresponding to the pylons of this segment.

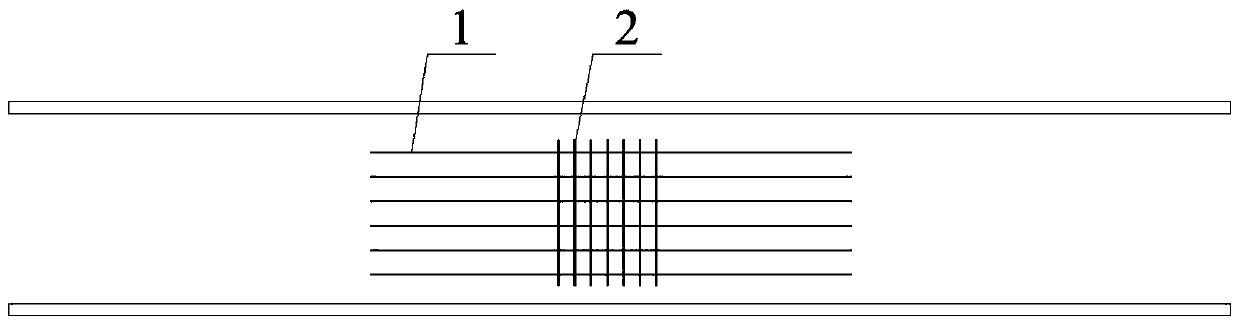

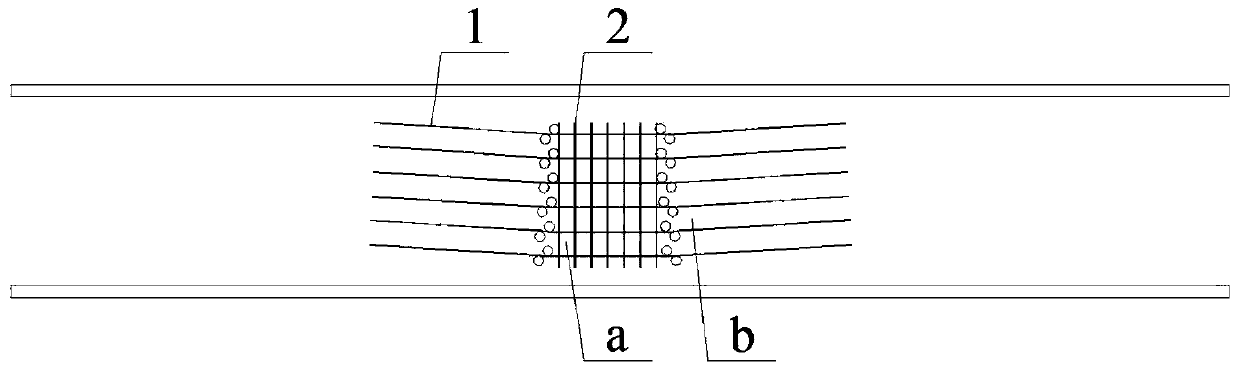

[0044] like Figure 1~5 As shown, the specific construction steps of the axial bending process in this embodiment are as follows: 1. figure 1 As shown, the stirrups 1 are arranged on the horizontal binding table according to the design spacing requirements along the horizontal transverse direction (the transverse direction in this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com