Method for Measuring Matte Liquid Level in Oxygen-enriched Bottom-blown Furnace

An oxygen-enriched bottom blowing furnace and matte technology, which is applied in the direction of the level indicator of the level members, can solve the problems of cumbersome measurement process, potential safety hazards, easy burns to workers, etc., to achieve flexible measurement time, no potential safety hazards, The effect of reducing copper content in slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

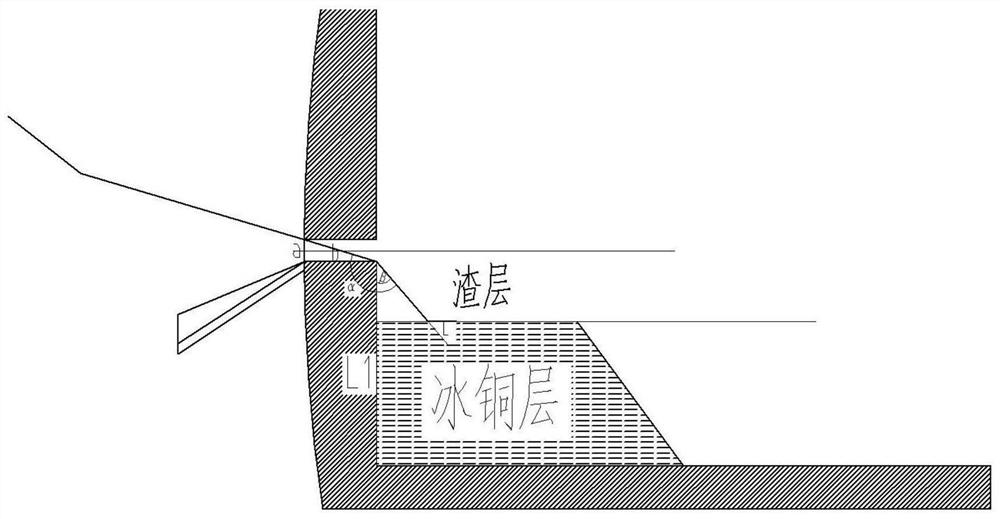

[0019] Such as figure 1 and figure 2 As shown, the method for measuring the matte liquid level in the oxygen-enriched bottom-blown furnace in the present embodiment may further comprise the steps:

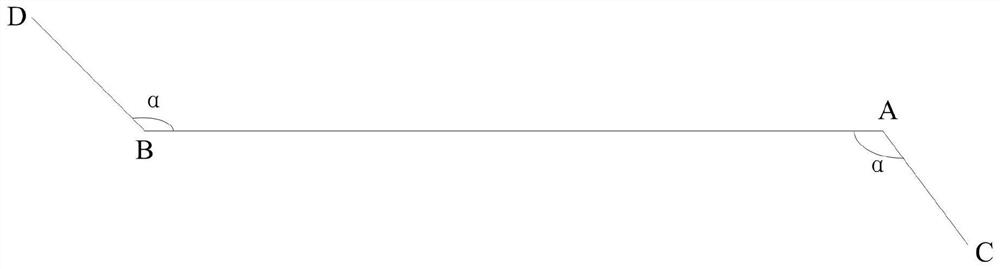

[0020] Step 1, making a measuring rod, the measuring rod includes a measuring section AC, an operating section BA and an angle adjustment section BD, the measuring section AC, the operating section BA and the angle adjustment section BD are in the same plane, and the measuring section AC and the angle adjustment section The length of the section BD is the same, and the angle between the angle adjustment section BD and the operation section BA and the angle between the operation section BA and the measurement section AC are both α;

[0021] Step 2. Align the measurement section AC with the slag mouth of the oxygen-enriched bottom-blown furnace upward, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com