Method and device for rechecking automobile malfunction, terminal device and storage medium

A technology for automobile failures and automobiles, applied in the direction of instruments, etc., can solve the problem of long time-consuming re-inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

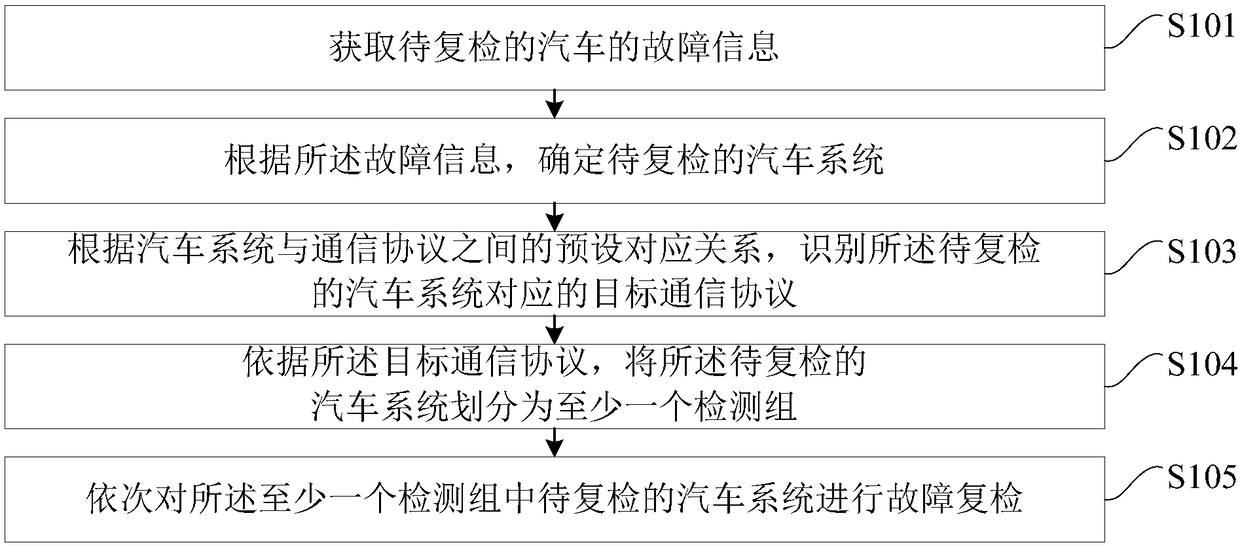

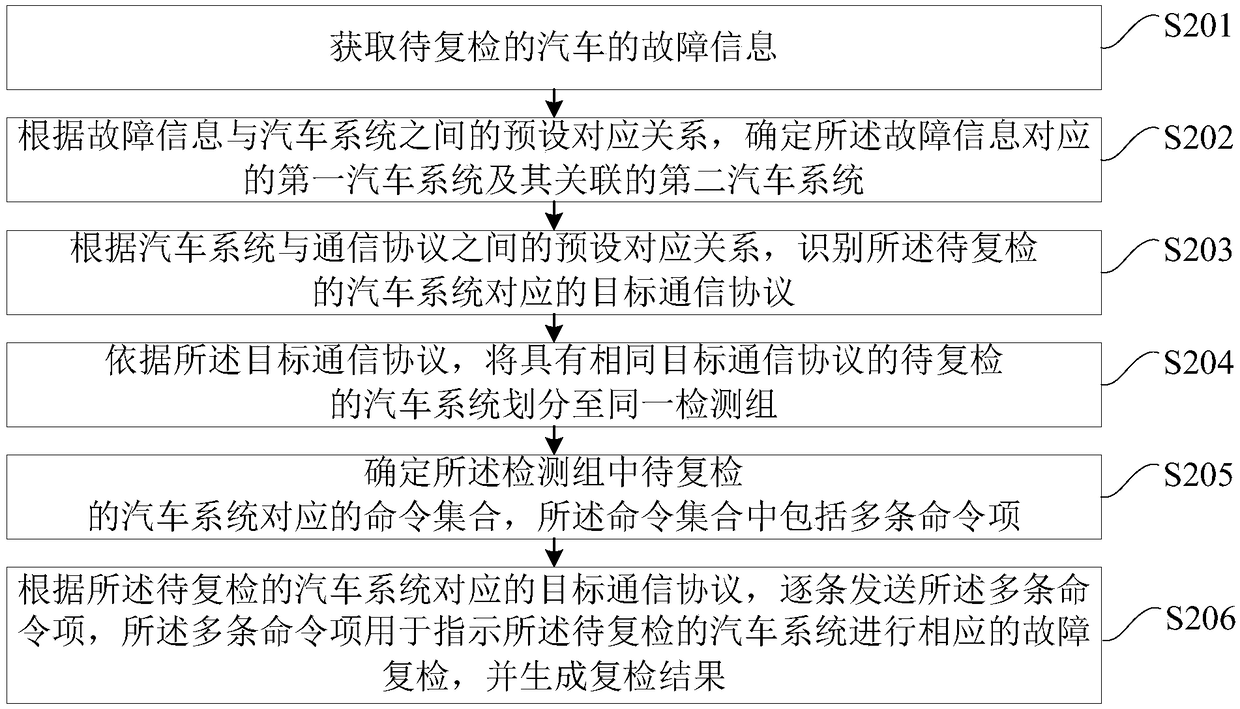

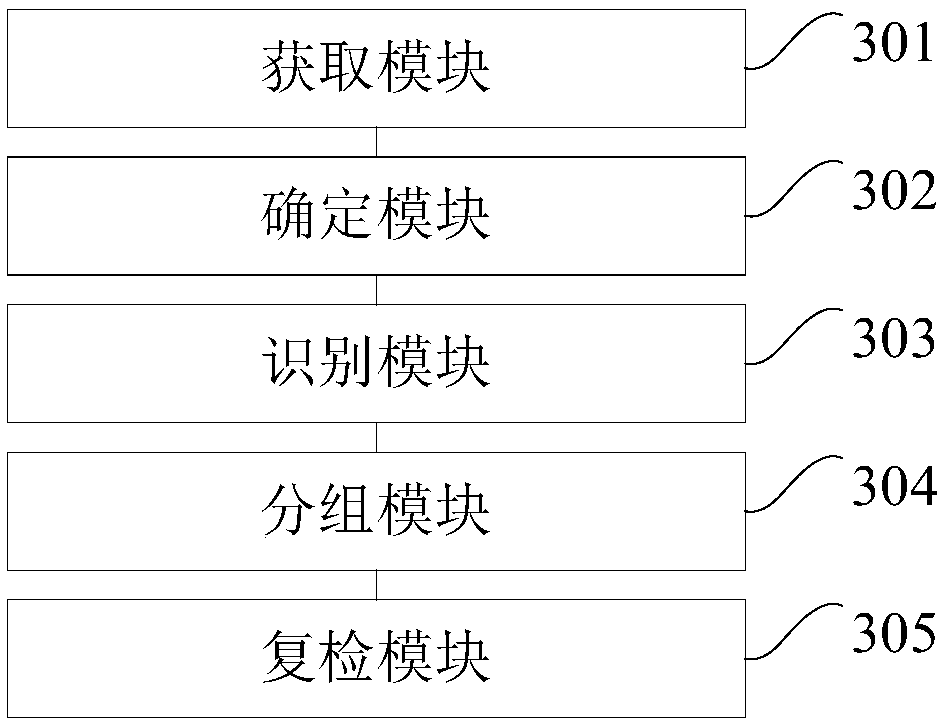

[0054] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0055] Usually, after a car breaks down, the maintenance personnel can detect the car's fault through the testing equipment, and then repair the car; after the maintenance, in order to determine whether the fault is eliminated, it is necessary to use the testing equipment for re-inspection. Under the current testing equipment and testing methods, the re-inspection often adopts the same method as the first inspection of the car, which requires tedious and time-consuming repetitive operations.

[0056] Taking the detection of a car engine as an example, the following steps are generally required:

[0057] 1. Select the car model software;

[0058] 2. Select the corresponding vehicle characteristics, such as production year, engine type, gearbox type, etc.;

[0059] 3. Select the corresponding system: engine system

[0060] 4. Select the corresponding diagnostic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com