A detachable double-sided bridge and a method for installing and disassembling the same

A double-sided bridge and detachable technology, which is applied in the field of detachable double-sided bridges, can solve problems such as unfavorable double-sided bridge repairs, maintenance, high processing and manufacturing costs, partial or overall deformation of steel components, etc., to improve material utilization and facilitate maintenance , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention, and the described embodiments are only part of the embodiments of the present invention, not all of them.

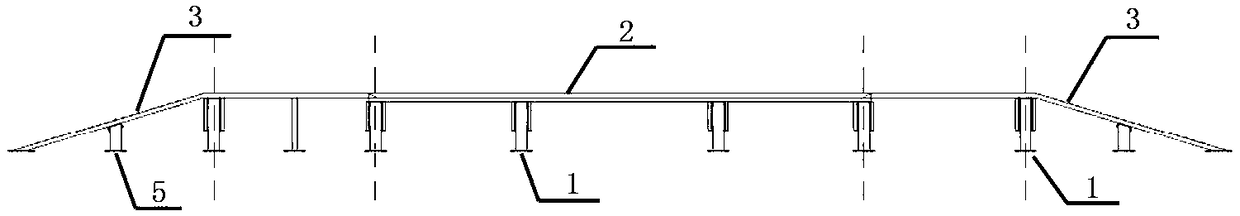

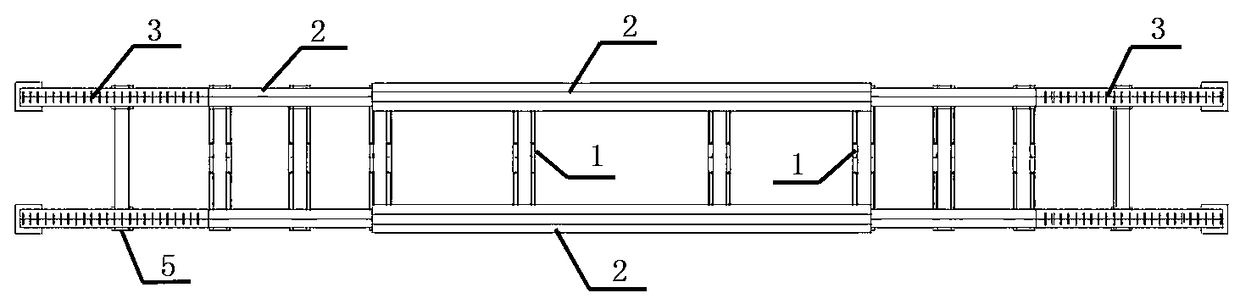

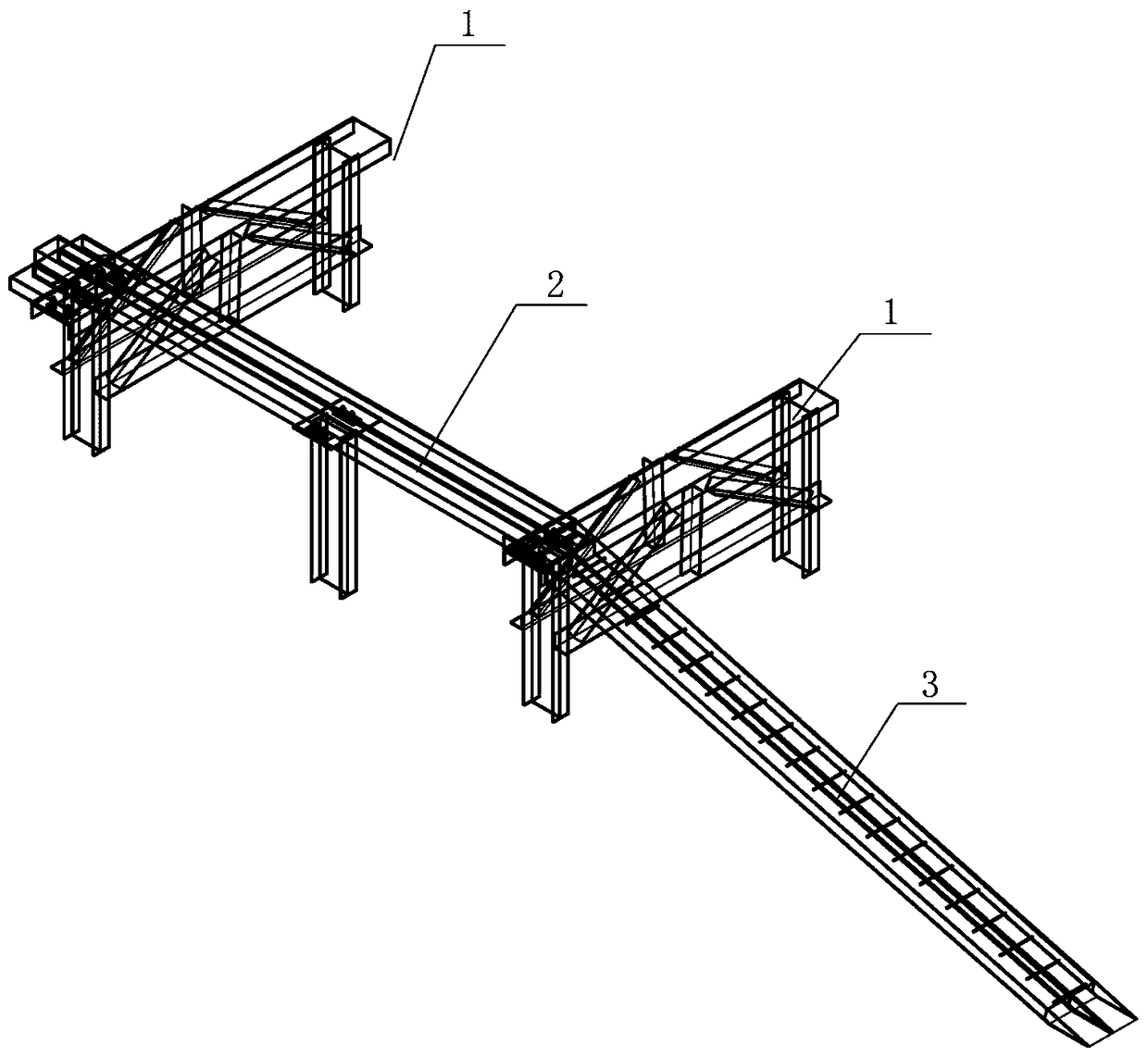

[0034] Such as Figure 1 to Figure 7 Shown, a kind of detachable bilateral bridge comprises bridge deck main body and the support base 1 of supporting bridge deck main body, and described bridge deck main body comprises the horizontal bridge deck 2 of middle part and the inclined deck 3 of two ends; Horizontal deck 2 and The inclined deck 3 has two parallel sides, and the horizontal deck 2 can be disassembled into multiple sections, each section is provided with bolt holes, and each section is assembled horizontally and connected by bolts 4-1 to form a horizontal deck 2. There is a connecting piece 4-2 between the inclined bridge deck 3 and the horizontal brid...

Embodiment 2

[0042] The installation and dismounting method of the bilateral bridge in embodiment 1 comprises the following specific steps:

[0043] 1) Install the support base: according to the length of each section of the horizontal bridge deck 2, place each support base 1 at a good distance and weld the steel plate at the bottom of the support base 1, drill holes around the steel plate, and fix the support base 1 on the ground with bolts; A steel plate is welded at the bottom of the beam 1-2, and 4 small holes are drilled at appropriate positions around it. In order to enhance the stability of the supporting base, the base is fixed on the ground with bolts;

[0044] 2) Install the horizontal bridge deck: place a steel plate on the top end of the supporting base 1 as the first connecting liner 4-3. Place 3 channel steels side by side on the connecting liner 4-3 as a side of the horizontal bridge deck 2, connect the first connecting liner 4-3 with the 3 channel steels by full welding, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com