Film thickness measurement system

A measurement system and film thickness technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of slow system response, long data transmission time, unable to meet the needs of high production capacity of film thickness, etc., to achieve the effect of facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] As mentioned in the background section, the mainstream film thickness measurement systems in the prior art have the technical problems of long measurement time and slow system response.

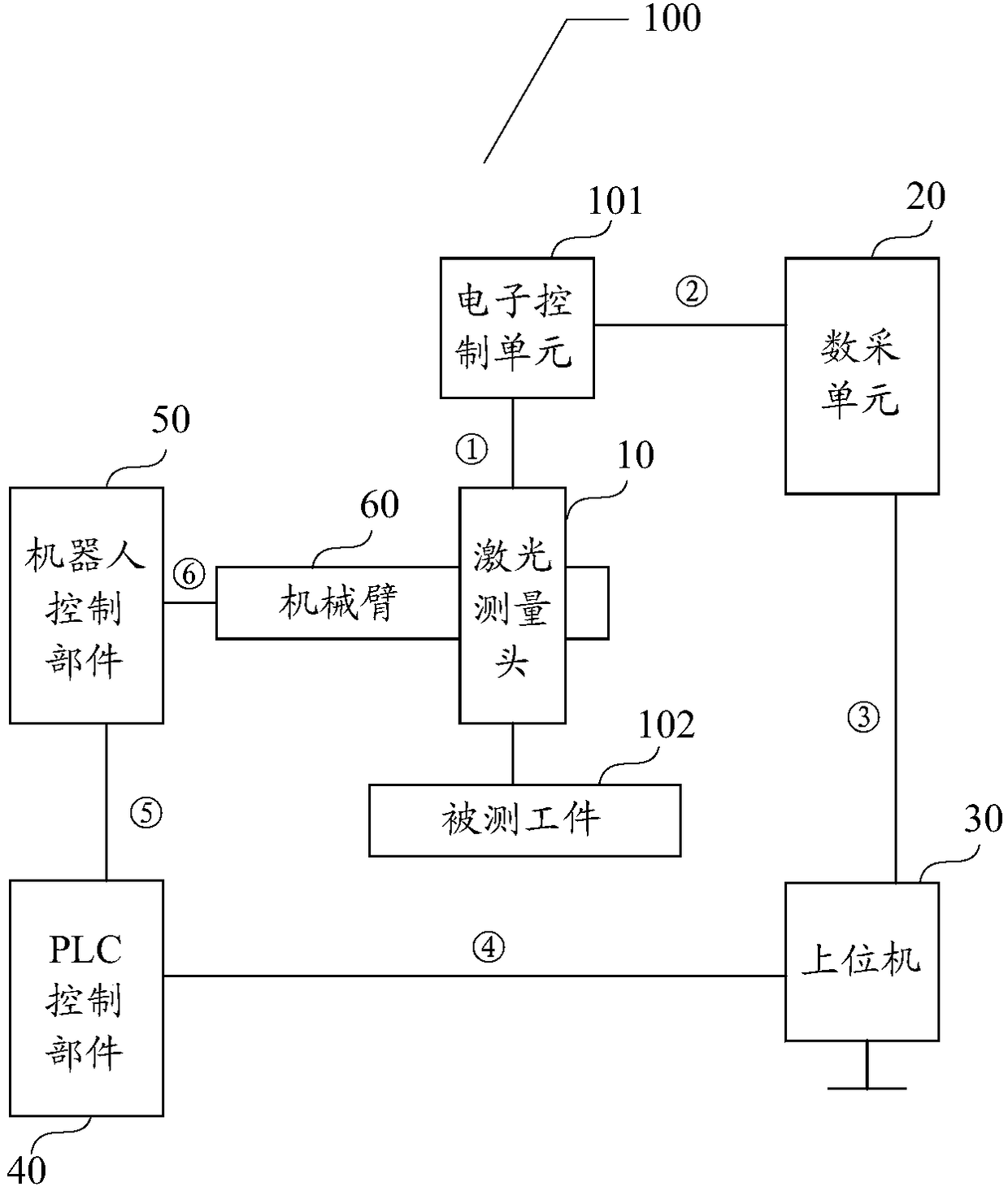

[0031] The inventor of this application is figure 1 The film thickness measurement system 100 is shown for further analysis. Continue to refer to figure 1 , the laser pulses generated by the laser measuring head 10 are controlled to heat the paint layer of the measured workpiece 102 (here, the measured workpiece 102 is an automobile subjected to electrophoretic painting as an example, and through the paint layer in the paint layer The electrophoretic immersion paint layer (KATAPHORESE TAUCH LACKIERUNG, referred to as KTL) reflects the attenuation heat wave, and the attenuation heat wave is transformed into the film thickness of the measurement point on the workpiece to be measured through the sensing unit (not shown) in the ECU101 electrical signal for the data acquisition unit 20 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com