Arc generating equipment and electric contact material anti-arc performance evaluation method

A technology for generating equipment and electric contacts, which is applied in the field of electrical testing, can solve problems such as lack of arc generating equipment and the inability to meet the evaluation requirements of electric contacts, and achieve the effects of controlling charging time, reducing selection requirements, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

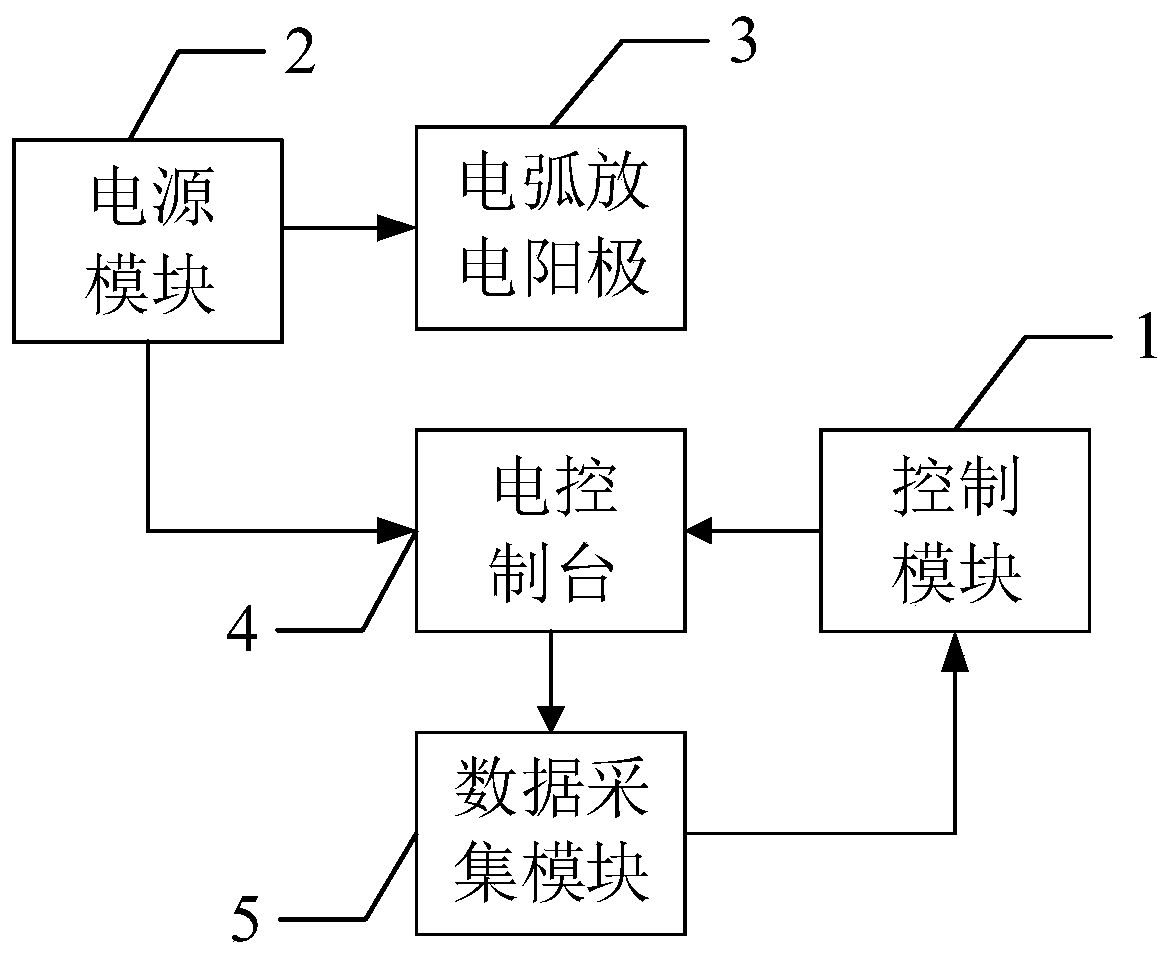

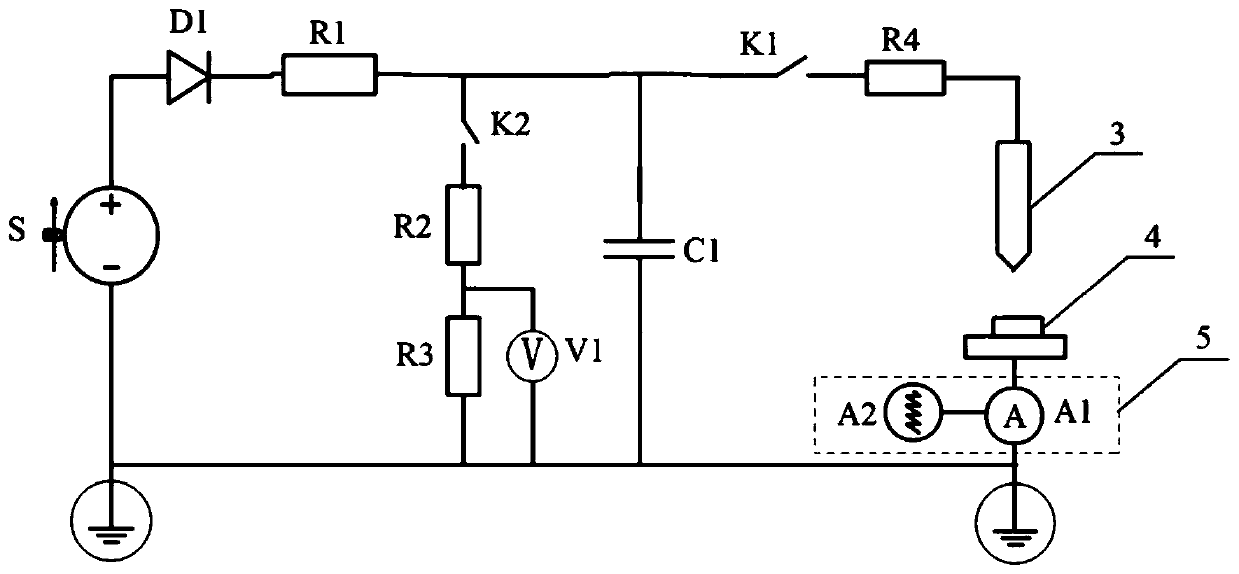

[0030] This embodiment provides an arc generating device, such as figure 1 As shown, it includes: a control module 1, a power module 2, an arc discharge anode 3, an electric console 4 and a data acquisition module 5.

[0031] Wherein, the anode of the power module 2 is connected with the arc discharge anode 3, and the cathode is connected with the sample of the electric contact provided on the electric console 4 to provide the arc discharge voltage; the electric console 4 is connected with the control module 1. connected to be close to or away from the arc discharge anode 3 according to the output signal of the control module 1; the data acquisition module 5 is arranged between the cathode of the power module 2 and the electric console 4, and is connected with the control module 1 to collect the arc discharge current during the discharge process, and send the discharge current to the control module 1.

[0032] In this embodiment, in order to meet the requirement that the arc ...

Embodiment 2

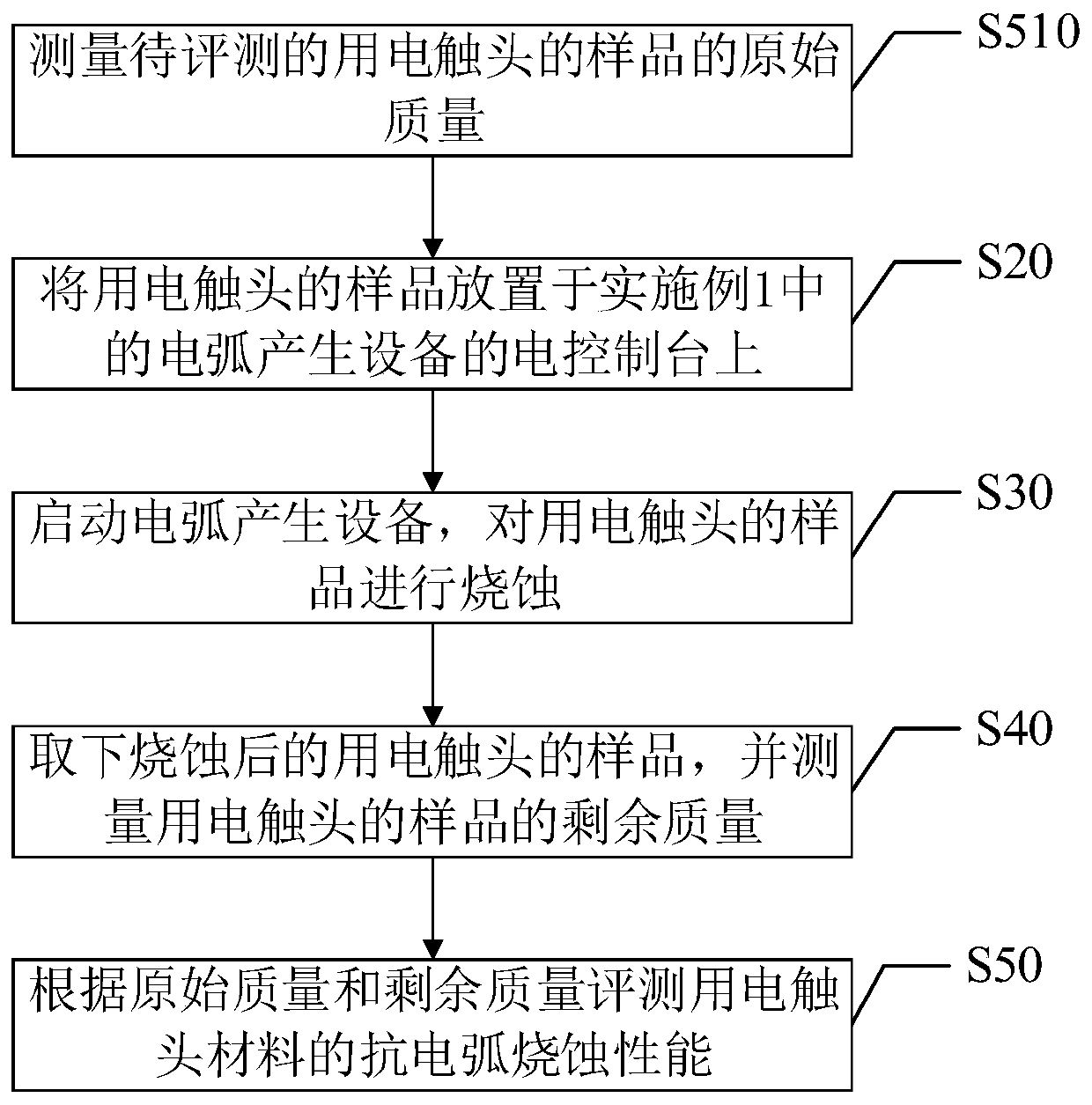

[0048] This embodiment provides a method for evaluating the arc ablation resistance performance of electrical contact materials, such as image 3 shown. It should be noted that this method is an application method of the arc generating device in Embodiment 1, and what has been explained in Embodiment 1 will not be repeated here. In addition, although the logical sequence is shown in the flow chart, In some cases, however, the steps shown or described may be performed in an order different from that presented here. The process includes the following steps:

[0049] Step S10, measuring the original quality of the sample to be evaluated for the electrical contact. In this embodiment, the sample needs to be made into a metallographic sample, and the surface is mechanically polished, and then ultrasonically cleaned in deionized water to remove oil stains on the sample surface, and dried. In this embodiment, a high-density electronic balance is used for weighing samples.

[0050...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com