Tool applicable to all-around welding of test boards

An all-round, tooling technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that the safety of welding personnel cannot be reliably guaranteed, the space occupied by test welding is large, and welding work takes a long time. , to achieve the effect of safe and reliable operability, small space occupied by test welding, and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

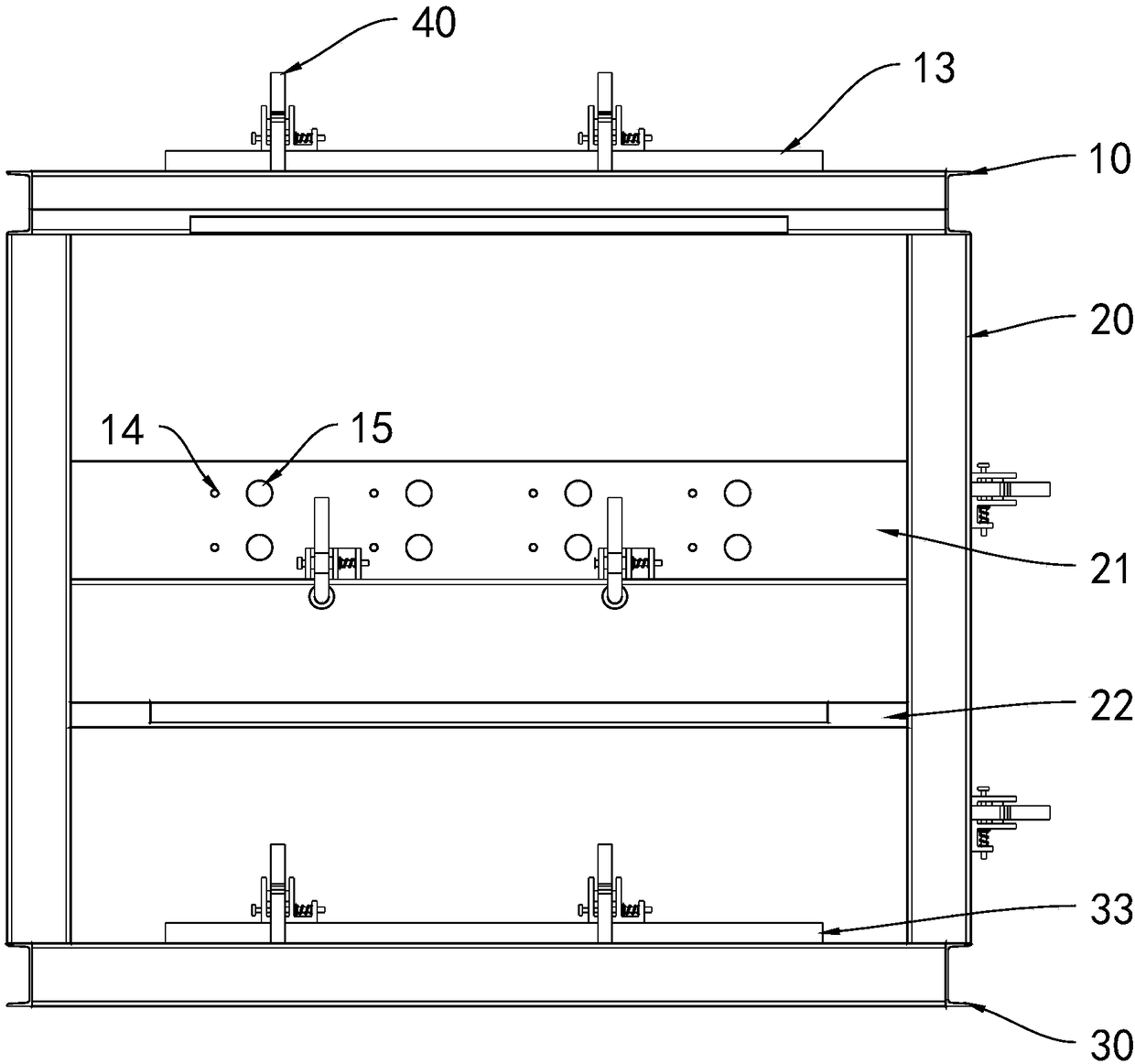

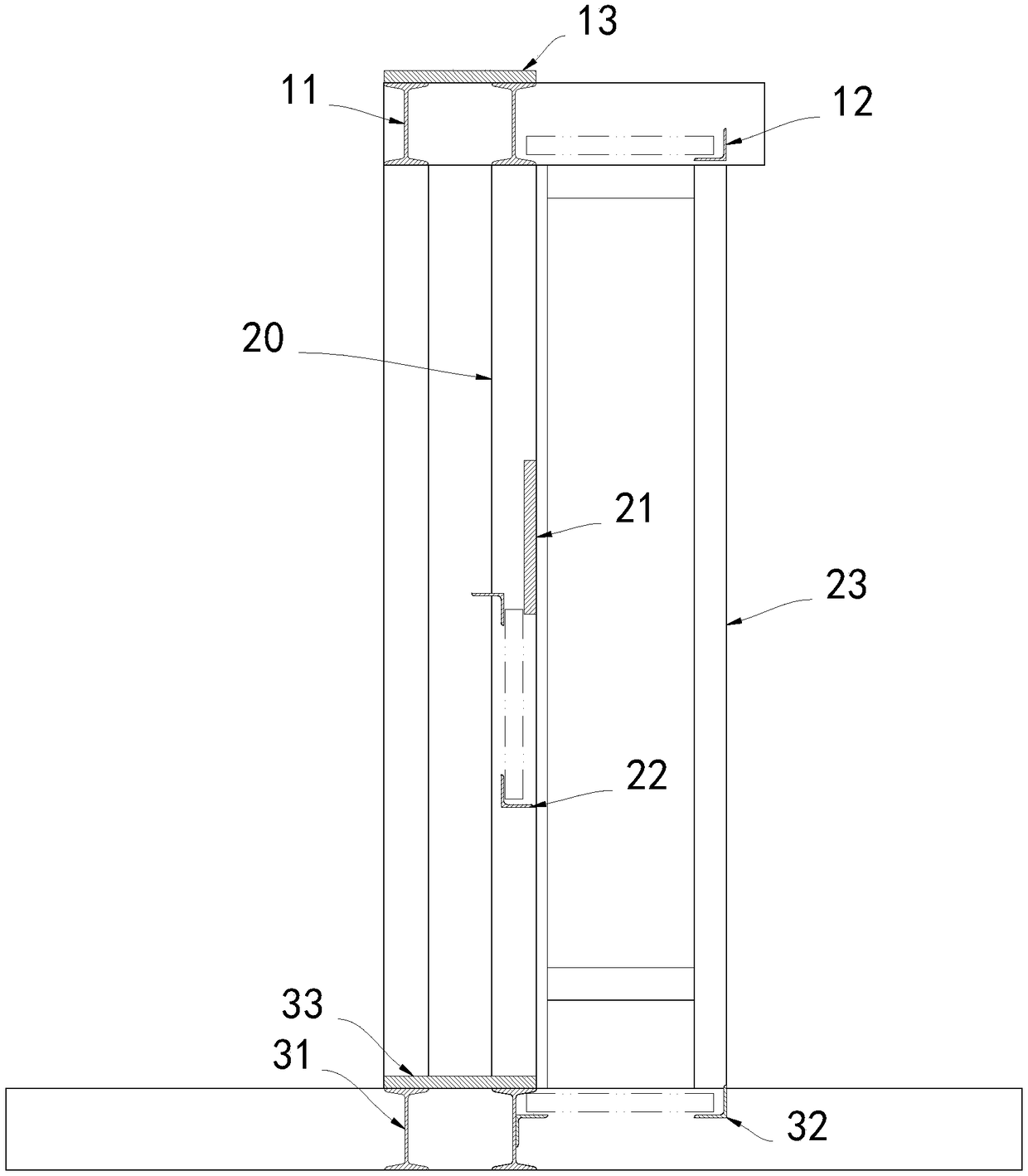

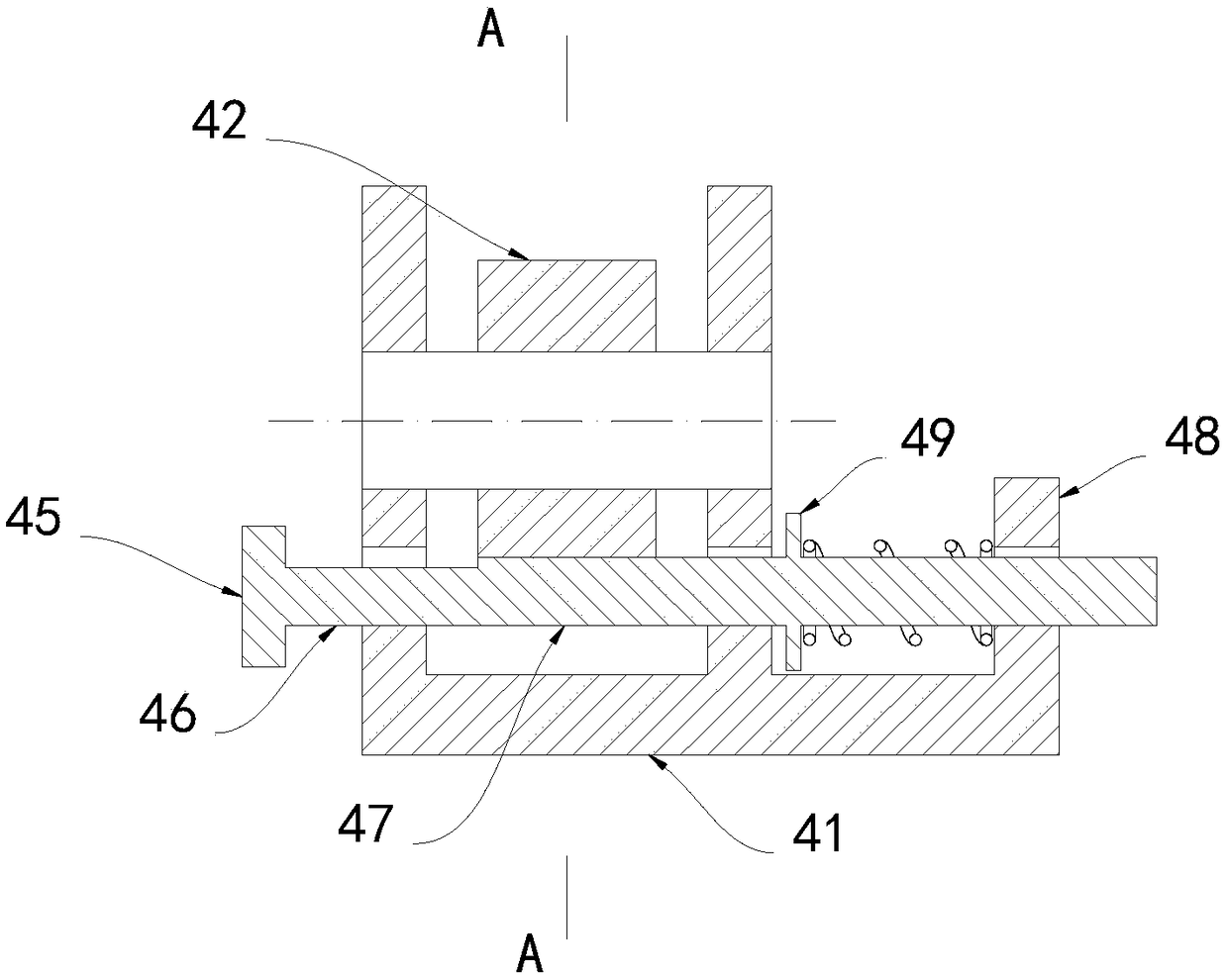

[0019] Embodiment: a kind of frock suitable for all-round welding of the test plate, constituted as figure 1 As shown in the figure [, it includes an upper beam 10, a column 20 and a lower beam 30 arranged in pairs; an upper I-beam 11 and an upper angle steel 12 forming a horizontal load-bearing structure of the test plate are arranged between the upper beams 10, and the upper An upper track support plate 13 is provided on the I-beam 11; a transverse track support plate 21 and a transverse angle steel 22 forming the transverse load-bearing structure of the test plate are arranged between the two columns 20, and a side angle steel 23 is provided on the side of one column 20 , the side angle steel 23 and the column 20 form the vertical load-bearing structure of the test plate; the lower I-beam 31 and the lower angle steel 32 forming the horizontal load-bearing structure of the test plate are arranged between the two lower beams 30, and the lower I-beam 31 is provided with The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com