Aggregate intermediate bin and concrete mixing station

A technology of intermediate silo and aggregate silo, which is applied in ingredients storage, clay preparation device, mixing operation control, etc., can solve the problems of worn aggregate intermediate silo and rear wall wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0029] In the present invention, in the case of no contrary description, the used orientation words such as "up, down, left and right" usually refer to the up, down, left and right shown in the accompanying drawings; "inside and outside" Refers to the inside and outside of the outline of each part itself. The present invention will be described in detail below with reference to the drawings and in combination with embodiments.

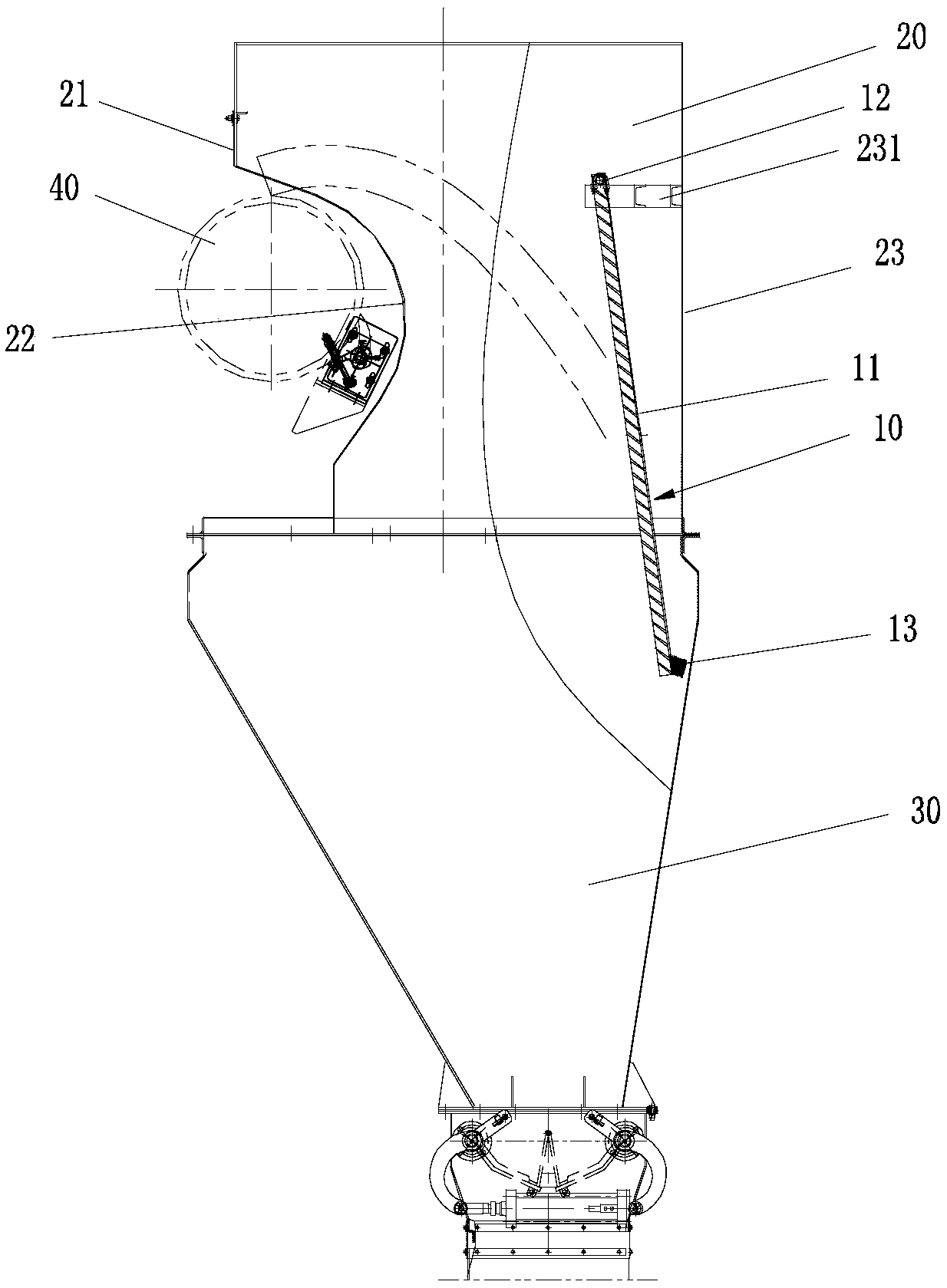

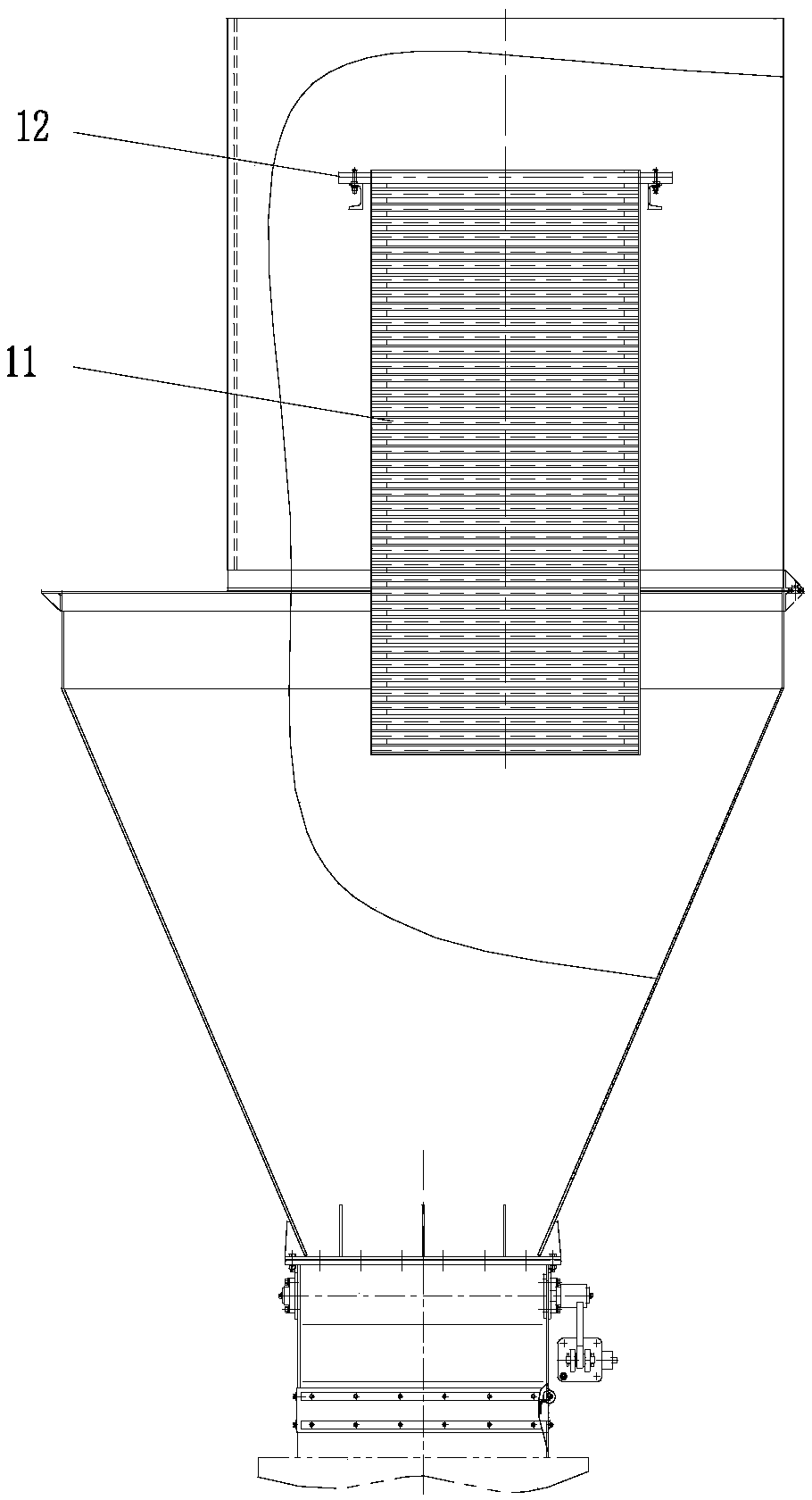

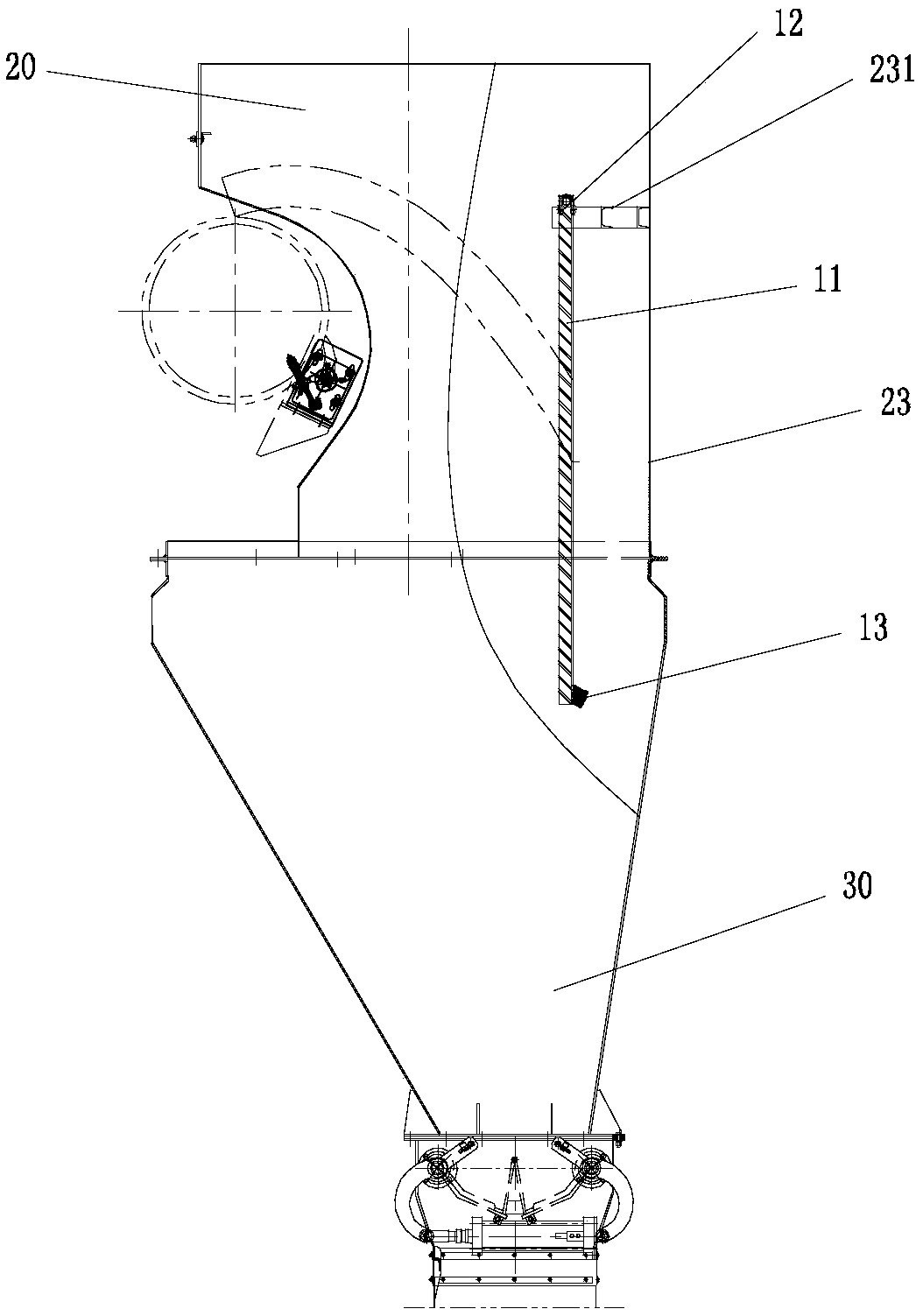

[0030] According to one aspect of the present invention, there is provided an aggregate intermediate silo, wherein the aggregate intermediate silo includes an anti-wear device 10, a head cover 20, and an aggregate bin 30 arranged under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com