An annular panel rib structure with distributed stiffness

A circular, distributed technology, applied in the direction of floating buildings, etc., can solve the problems of uneven distribution of structural stress, different strength of support, local stress concentration, etc., to achieve good vibration isolation ability, simple and clear structural form , the effect of reducing the level of sound radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

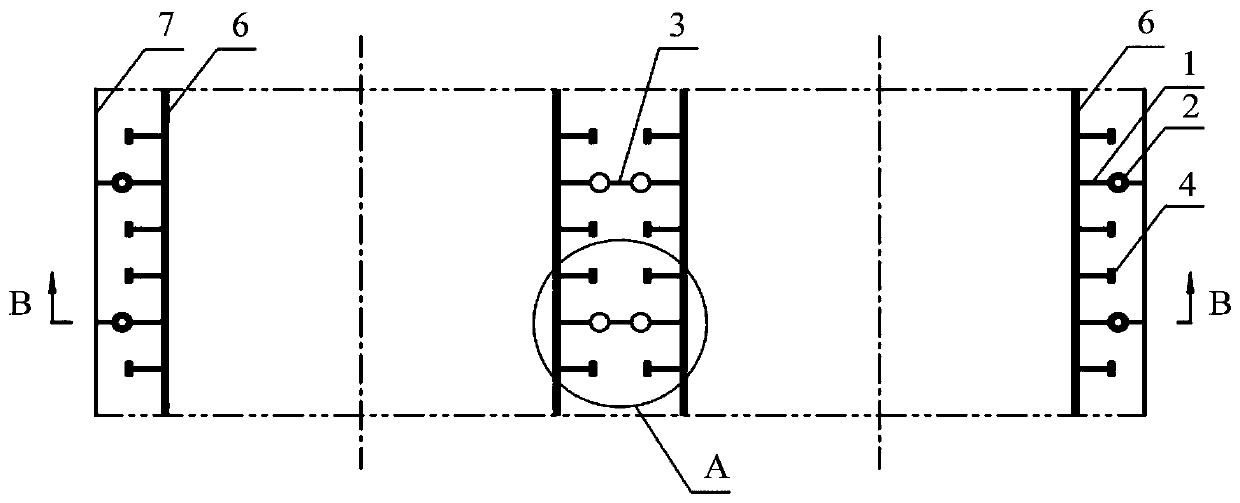

[0031] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

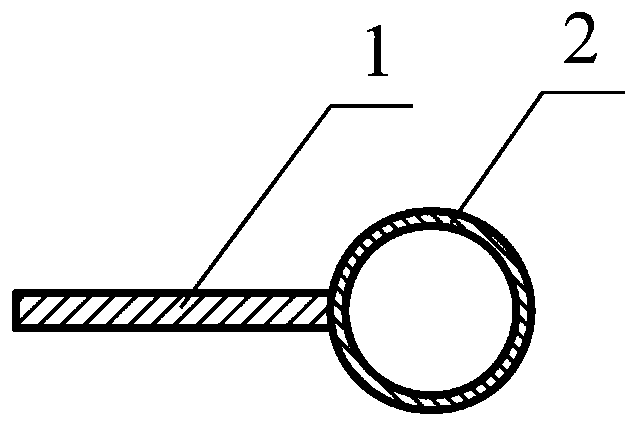

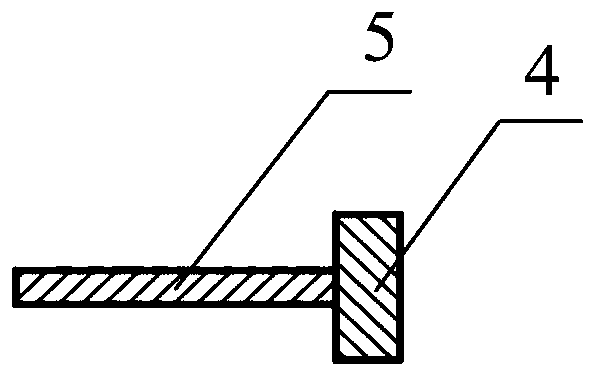

[0032] The fixed connection structure connects the inner pressure-resistant shell and the outer non-pressure-resistant shell of the platform. On the one hand, it plays the role of transferring load and deformation between the inner and outer double-layer shells. Therefore, the design of the fixed connection structure plays a key role in the sound radiation level of the platform. In view of the defects in the prior art, the embodiment of the present invention proposes a circular panel rib structure with distributed stiffness. Since the pressure-resistant rib panel is the installation basis of the deep-sea platform fixed structure, the present invention is applied to the fixed structure In the design of the platform, the conversion of the fixed connection structure from rigidity to elasticity can be realized, thereby eliminating or reducing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com