A design method for on-line fault detection of high-speed railway traction system

A traction system and fault detection technology, applied in the direction of calculation, computer parts, signal pattern recognition, etc., can solve the problems that the change characteristics are not obvious, not suitable for small fault diagnosis, etc., and achieve the effect of improving the detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

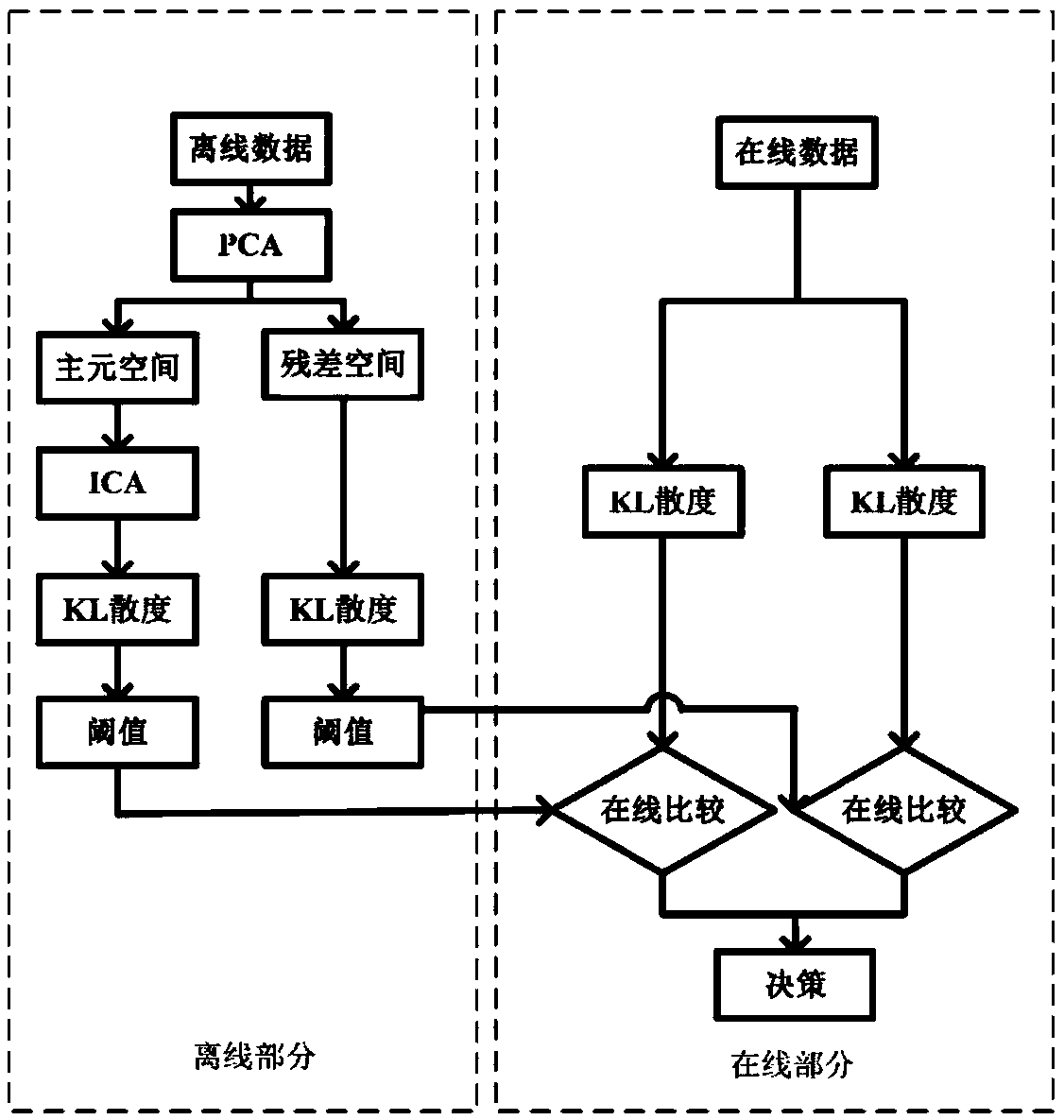

[0053] The technical solutions and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0054] The present invention provides a system design method for detecting and locating minor faults of an electric traction system, comprising the following steps:

[0055] In the offline stage, the high-speed rail has not been running offline, and the accumulated historical data of normal operation is used:

[0056] (1) Store the operating data of the high-speed rail traction system under normal operating conditions;

[0057] (2) Process the stored data with PCA and map it to the pivot space and residual space;

[0058] (3) In the principal component space, use ICA to extract features of non-Gaussian components;

[0059] (4) For the data processed by ICA and the data in the residual space, the statistics are defined according to the Kullback-Leibler divergence;

[0060] (5) Determine the threshold of the statisti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com