Maintenance experience system and method of rail transit equipment based on VR and BIM technology

A technology for rail transit and equipment, applied in image data processing, 3D modeling, instruments, etc., can solve problems such as equipment not working properly, lack of maintenance personnel, equipment damage, etc., to achieve the effect of improving maintenance speed and maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

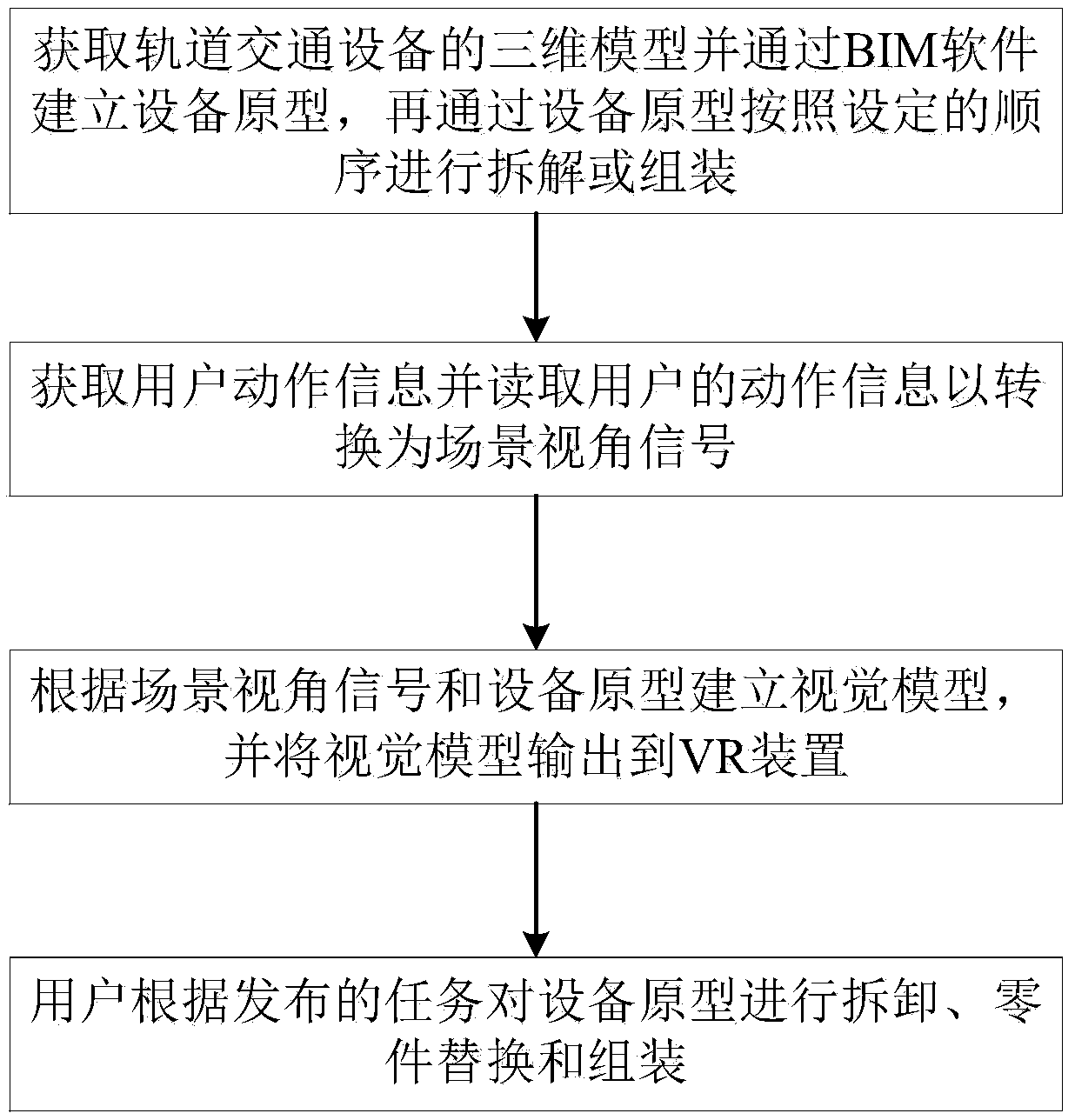

[0020] The rail transit equipment maintenance experience method based on VR and BIM technology provided in this embodiment includes:

[0021] (1) Obtain the BIM model file of the equipment and establish a prototype of the equipment; the parts of the equipment obtained through the 3D scanning device can be named according to the order of assembly, which is convenient for the acquisition of the BIM model file and the establishment of the equipment prototype. The BIM software then converts the BIM model files are assembled into an overall device model;

[0022] (2) Obtain user motion information and read the user’s motion information to convert it into a scene angle signal. The operator puts on the VR device, and the VR device automatically obtains the user’s motion information and converts the user’s motion information into a scene angle signal, which is convenient for follow-up The operator operates the equipment to have a formal sense of experience;

[0023] (3) Establish a v...

Embodiment 2

[0025] The rail transit equipment maintenance experience system based on VR and BIM technology provided in this embodiment includes a computer, a 3D scanning device, a VR device, a gateway device and a shared screen. The 3D scanning device can perform three-dimensional scanning on the parts and the whole of the equipment to form a BIM model file, and the BIM model file will be transmitted to the computer, which is equipped with BIM software and model building software, and the BIM software obtains the BIM model file and Assemble the BIM model file into a device prototype, and each component (BIM model file) can be disassembled according to the set operation command; the VR device obtains the user's motion information and reads the user's motion information to convert it into a scene perspective signal, The scene visual signal is sent to the computer, and the model building software in the computer obtains the scene visual signal and the equipment prototype to establish a visual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com