Miniature manually-operated lathe

A kind of lathe, small-scale technology, applied in the field of automation and machine tool technology, can solve the problems that are not suitable for the practical teaching of mechanical students, the structure of the lathe is complex, and the effect is not very good, so as to promote the theoretical study and practice, and the intuitive understanding of the working principle , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

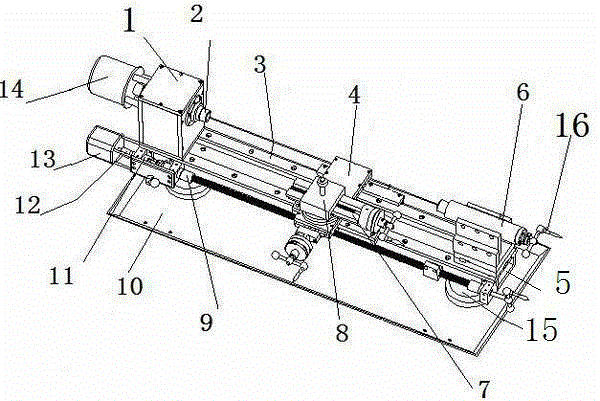

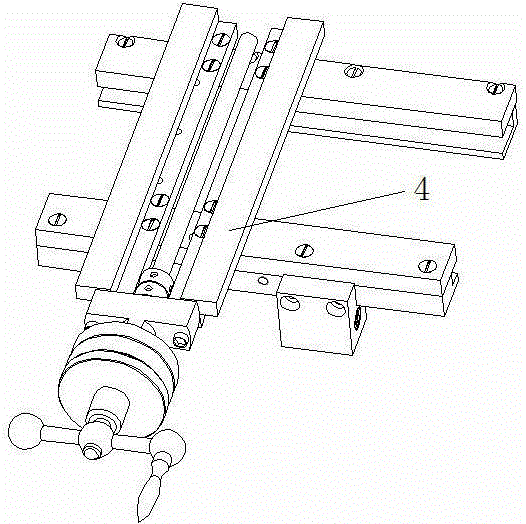

[0011] figure 1 A schematic diagram of the overall structure of the small manual lathe device of the present invention is given. The headstock 1, the tailstock 6, the tool post 8, the guide rail 3, the base 15, the material receiving plate 10, the bed 5, the headstock 1 and the tailstock 6 are respectively installed on the left and right ends of the bed 5, a base 15 is installed underneath the base 15, a material receiving plate 10 is arranged under the base 15, a guide rail 3 is provided on the bed 5, and the guide rail 3 passes The guide rail pair is connected with a Y-axis feeding device 4, the Y-axis feeding device 4 is installed with an X-axis feeding device 7, and the X-axis feeding device 7 is installed with a tool holder 8. One side of the shaft feeding device 4 is connected to the main screw 9 through threads; the right end of the main screw 9 is connected to the bed 5 through a bearing, and the left end is connected to the main screw motor 13 through a coupling 12; A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com