CMOS (complementary metal oxide semiconductor) inverter mold for teaching

A technology of inverters and molds, applied in the field of CMOS inverter molds for teaching, can solve the problems of being unable to intuitively understand and view the structure and manufacturing process of CMOS inverters, so as to improve learning interest and learning efficiency, and improve production efficiency , The effect of saving printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 is basically as attached figure 1 Shown:

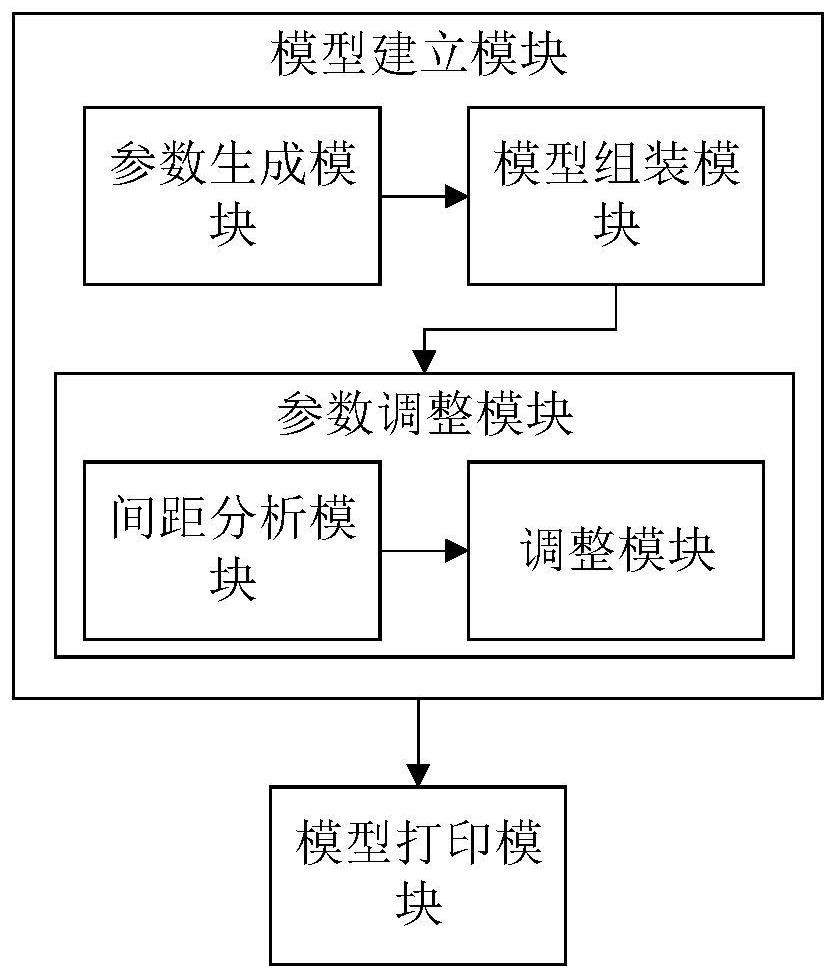

[0038] A CMOS inverter mold for teaching, such as figure 1 As shown, it includes model building module and model printing module. The model building module includes a parameter generation module, a model assembly module and a parameter adjustment module.

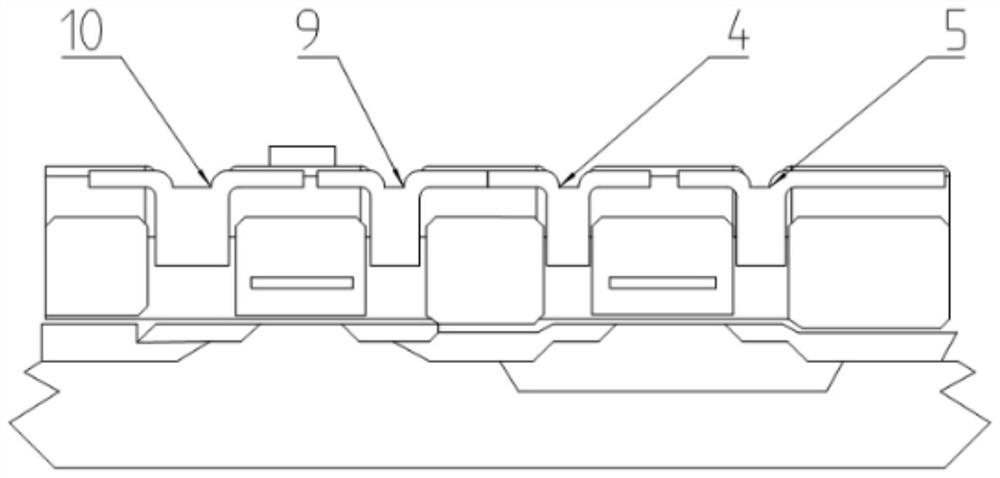

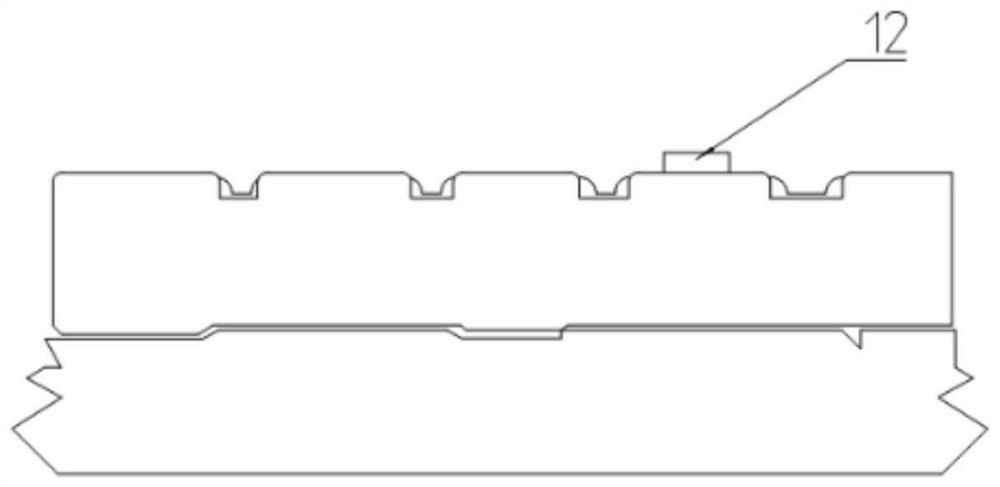

[0039] The parameter generation module is used to generate mold parameters of several mold parts. In this embodiment, the mold part includes a P-type substrate 1, an N-type hydrazine structure 2, an N+ injection region 3, an N-type drain electrode 4, an N-type source electrode 5, an N-type gate region 6, a P-type Hydrazine structure 7 , P+ injection region 8 , P-type drain electrode 9 , P-type source electrode 10 , P-type gate region 11 and gate electrode 12 . The mold parameters include the shape, size and color of each mold part. In this embodiment, the colors of each mold part are different, so as to distinguish each mold part. Wherein, the N-type drain e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com