Dry isolation transformer

An isolation transformer and dry-type technology, applied in the direction of transformers, fixed transformers, transformer/inductor cores, etc., can solve the problems of main insulation distance, dry arc distance, insufficient creepage distance, poor insulation withstand voltage, etc., to achieve High energy transfer efficiency, improved insulation withstand voltage capability, and increased main insulation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

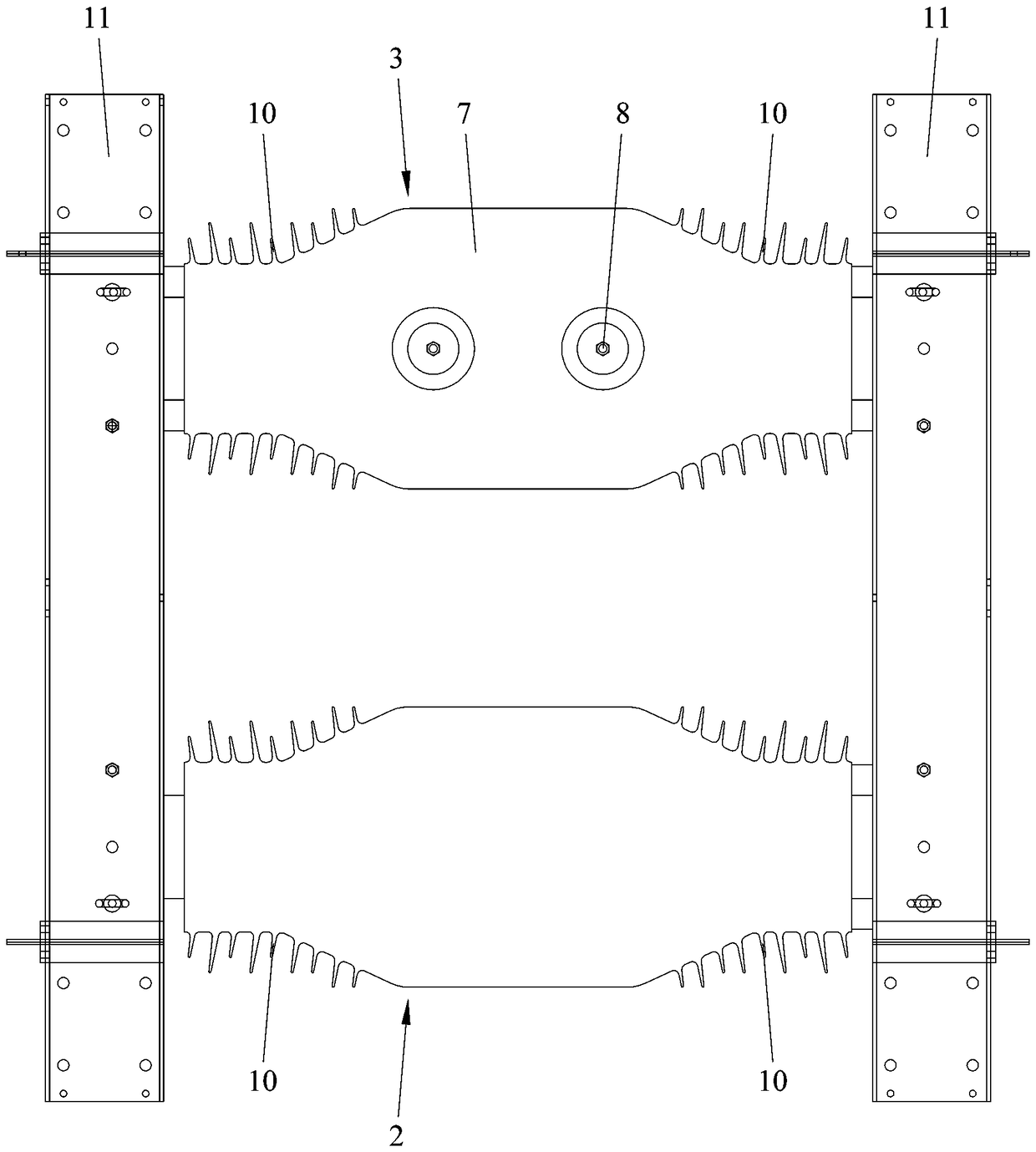

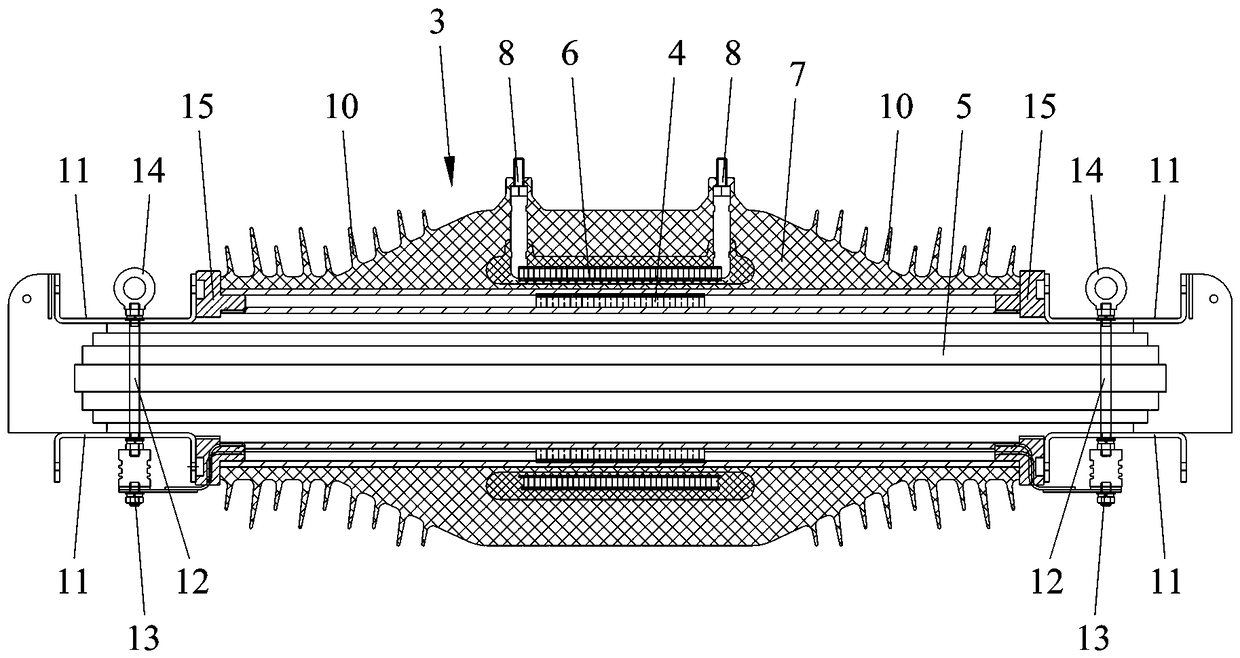

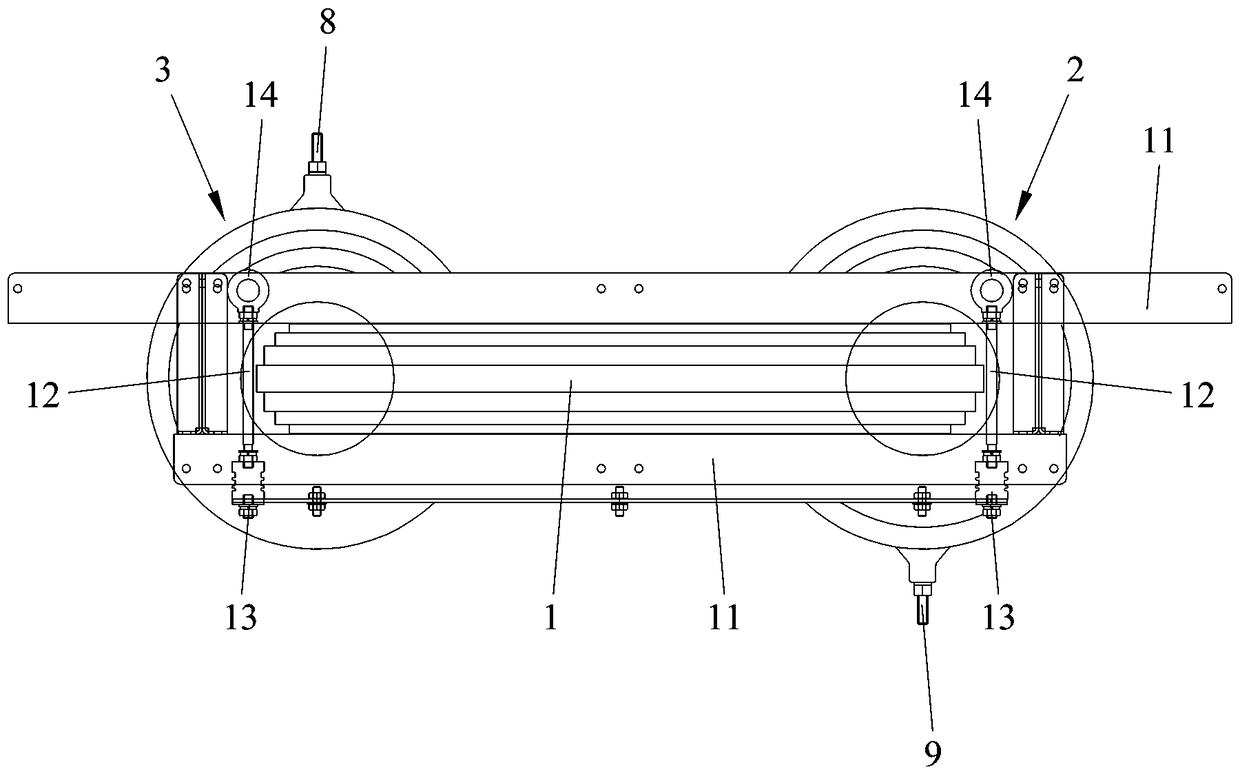

[0022] Embodiment one: as attached figure 1 To attach image 3 As shown, a dry-type isolation transformer includes a core 1 , an input winding 2 , an output winding 3 , and an intermediate winding 4 .

[0023] The iron core 1 includes two separate and connected iron core legs, respectively referred to as a first iron core leg and a second iron core leg 5 , and the iron core legs have an axis. The intermediate winding 4 for transferring energy includes a first part N1' and a second part N2', and the two ends of the two parts are correspondingly connected to form a loop. The first part N1' of the intermediate winding 4 and the input winding 2 are arranged on a core leg, that is, the first core leg, the first part N1' of the intermediate winding 4 is wound in the middle of the first core leg, and the input winding 2 is arranged on the The first part N1' of the intermediate winding 4 and the outer circumference of the first core leg where it is located. The second part N2' of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com