Support frame for planting

A support frame and hollow column technology, applied in application, cultivation, agriculture, etc., can solve the problems of troublesome fruit picking, inconvenient pruning of branches and leaves, high height, etc., and achieve the effect of self-locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

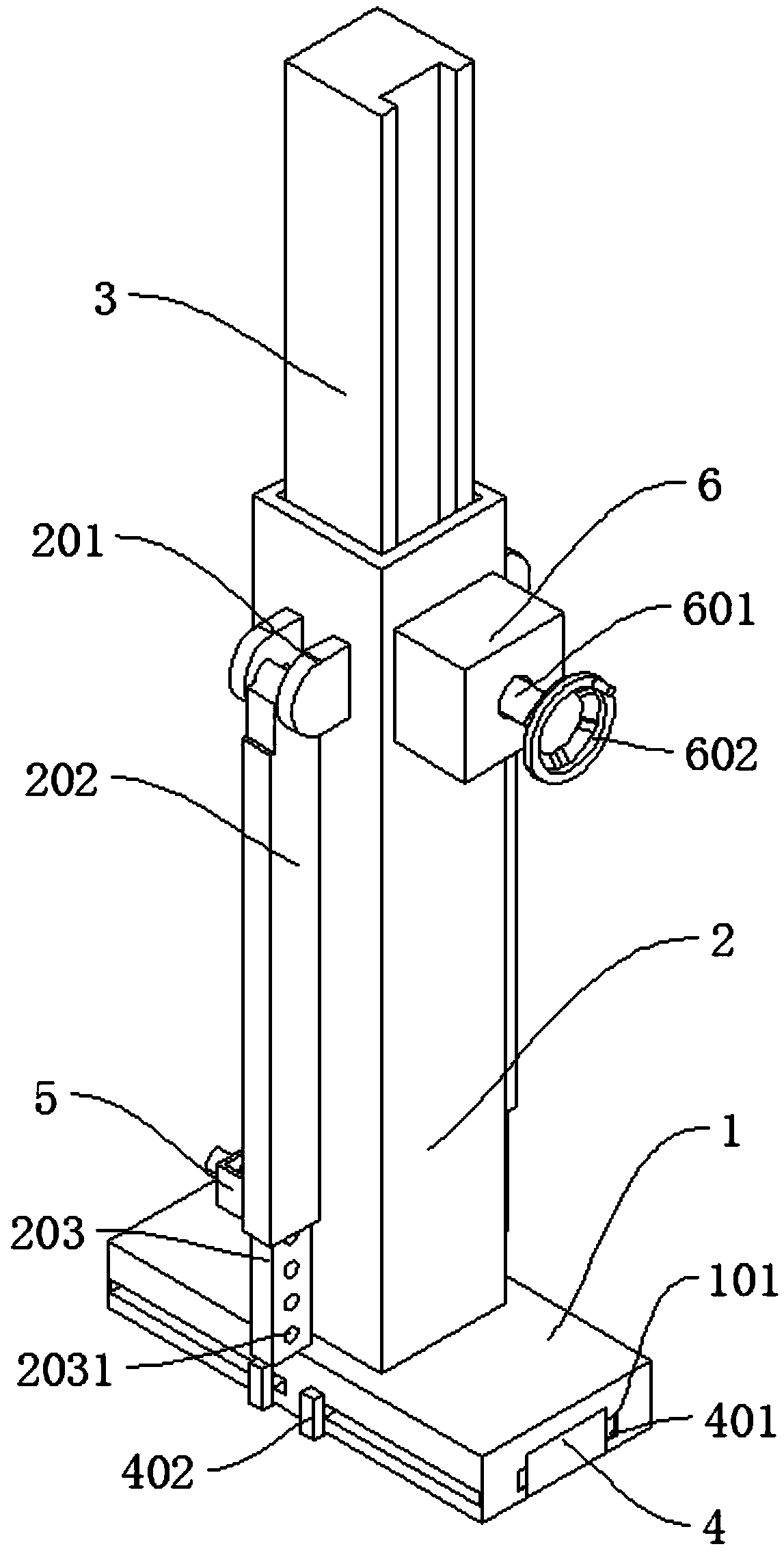

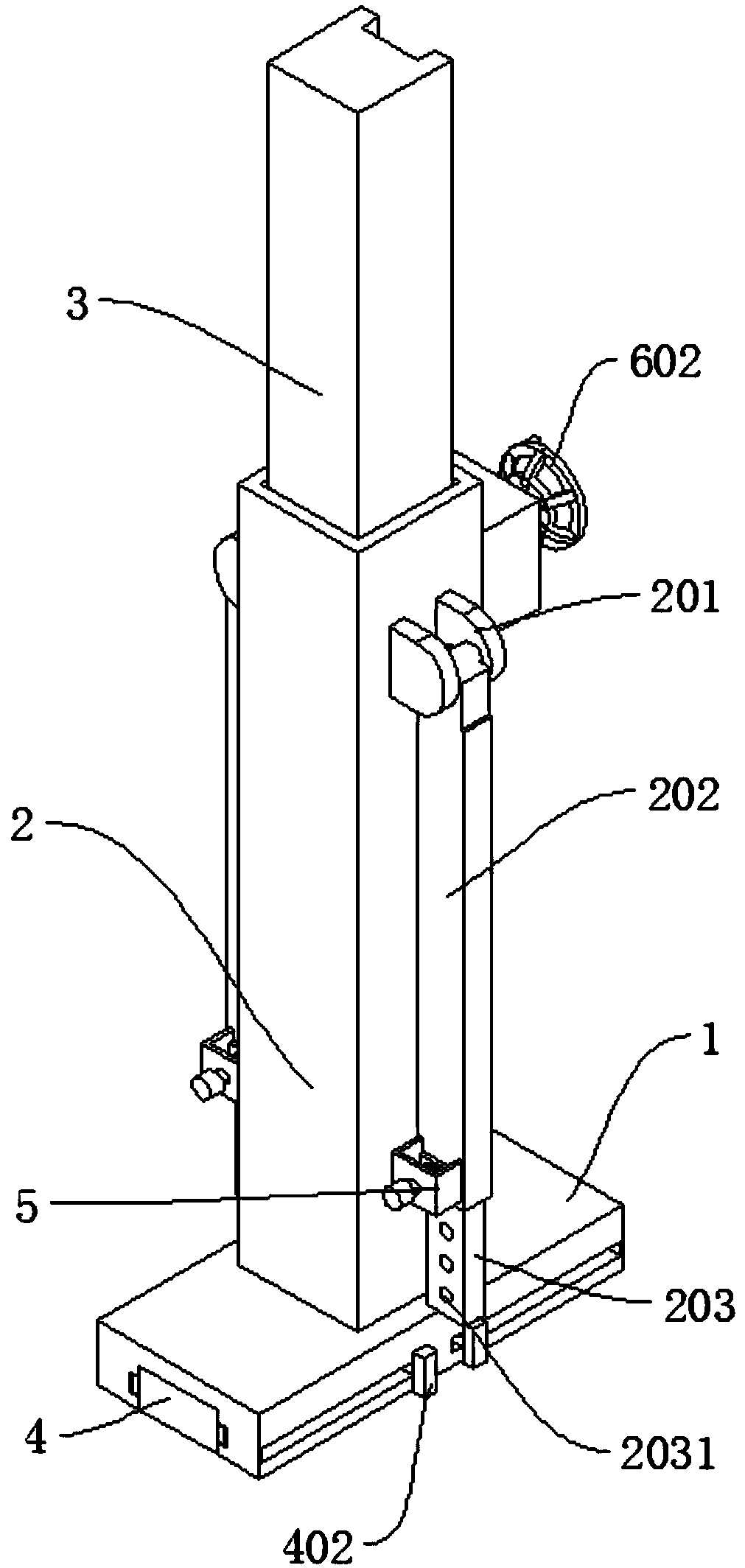

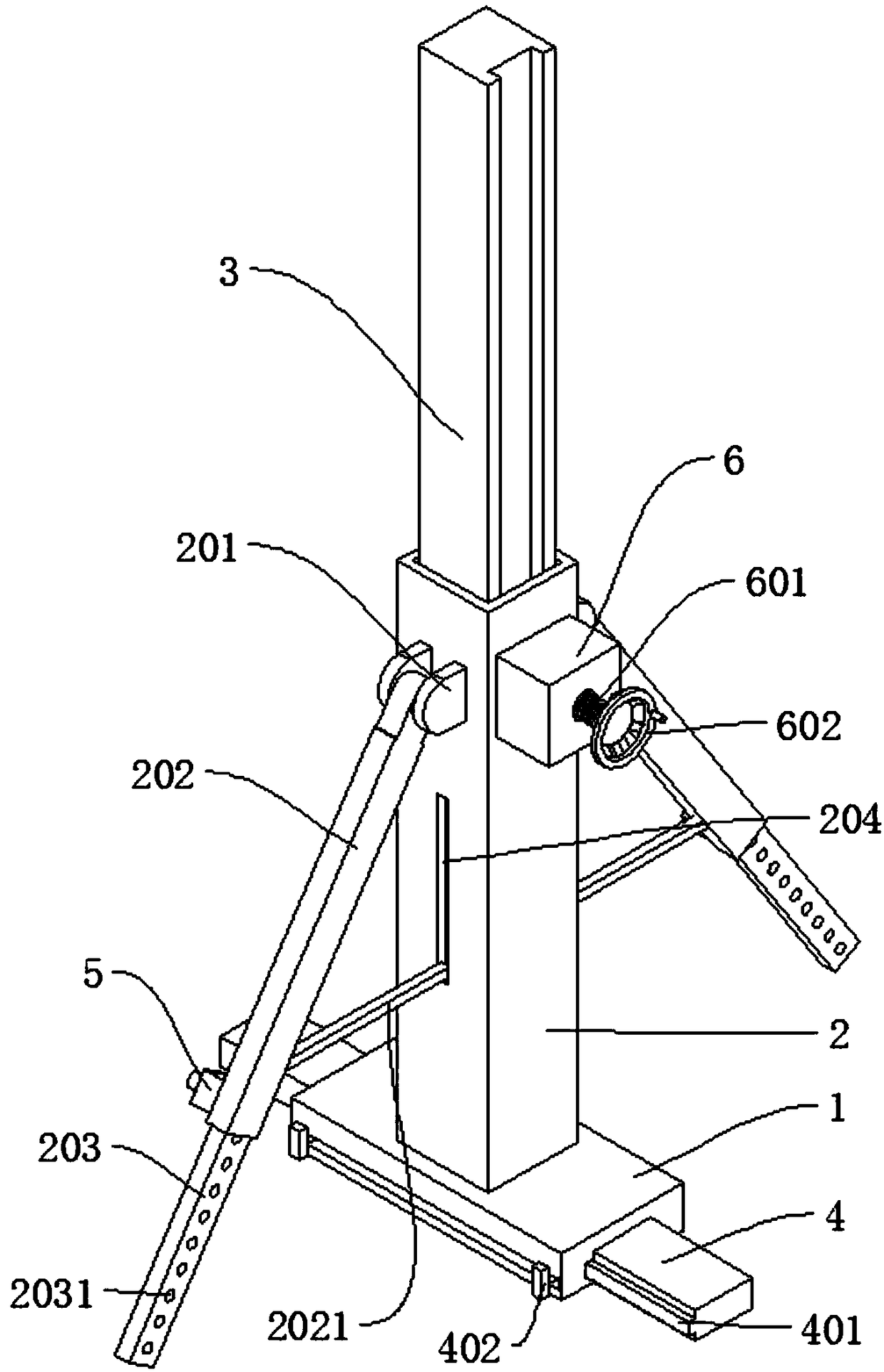

[0032] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 , a support frame for planting, comprising a base 1, a first hollow column 2, a first sliding bar 3, a second hollow column 202, and a second sliding bar 203, the first hollow column 2 is fixedly connected to the top of the base 1, the second A sliding rod 3 is slidably connected in the first hollow column 2, the second hollow column 202 is rotatably connected to the outer wall of the first hollow column 2 through a pin shaft 201, and the second sliding rod 203 is slidably connected in the second hollow column 202, The base 1 is symmetrically slidably connected to the two outriggers 4. When using, the user first pulls out the outrigger 4, and then rotates the second hollow column 202 to an appropriate angle, and then pulls out the second sliding rod 203. Therefore, it plays a supporting role, and the height can be adjusted conveniently by moving the first slide bar 3 upward.

Embodiment 2

[0034] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 , a support frame for planting, comprising a base 1, a first hollow column 2, a first sliding bar 3, a second hollow column 202, and a second sliding bar 203, the first hollow column 2 is fixedly connected to the top of the base 1, the second A sliding rod 3 is slidably connected in the first hollow column 2, the second hollow column 202 is rotatably connected to the outer wall of the first hollow column 2 through a pin shaft 201, and the second sliding rod 203 is slidably connected in the second hollow column 202, The base 1 is symmetrically slidably connected to the two outriggers 4. When using, the user first pulls out the outrigger 4, and then rotates the second hollow column 202 to an appropriate angle, and then pulls out the second sliding rod 203. Therefore, it plays a supporting role, and the height can be adjusted conveniently by moving the first slide bar 3 upward.

[0035] The number of the...

Embodiment 3

[0037] refer to Figure 1-7 , a support frame for planting, which is basically different from Embodiment 2. Furthermore, the side wall of the second hollow column 202 is connected with a first box body 5, and a connecting rod 501 is slidably connected to the first box body 5, and the connecting rod The upper end of the 501 is fixedly connected with a handle 502, the lower end of the connecting rod 501 is fixedly connected with a baffle 503, the bottom of the baffle 503 is connected with an insertion rod 504, and the second sliding rod 203 is provided with a slot 2031 corresponding to the insertion rod 504, A spring 505 is sleeved on the connecting rod 501, and the two ends of the spring 505 respectively resist the first box body 5 and the baffle plate 503. The body 5 slides, and then drives the insertion rod 504 to move out of the slot 2031 on the second slide rod 203, and then pulls the second slide rod 203 outward. After the position is adjusted, the spring 505 drives the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com