Baking device for producing tea leaves

A baking device and tea technology, which is applied in tea processing before extraction, etc., can solve the problems of not having the function of turning over the tea leaves, unevenness, backlog and turning of tea leaves, etc., and achieves the convenience of spreading and recycling, ensuring uniformity and convenience The effect of installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

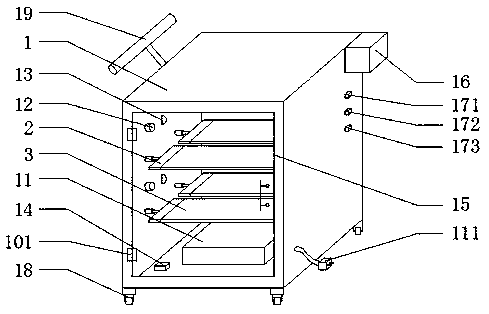

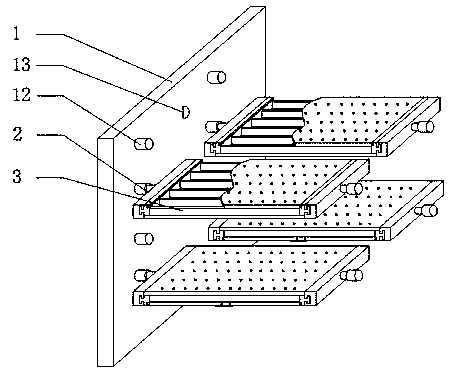

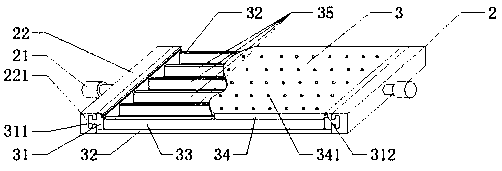

[0024] Embodiment 2: as Figure 1-Figure 4 As shown, a baking device for tea production includes a box body 1, a hot air generator 11 is installed on the upper side of the bottom of the box body 1, and a rotary turning device 2 is installed on the inner side of the box body 1, and the rotating turning surface The device 2 is located at the top of the hot air generator 11; the rotating turning device 2 includes a first stepping motor 21, and the first stepping motor 21 is installed on the inside of the side plate of the casing 1, and the first stepping motor 21 outputs One side of the baking support plate 22 is installed at the end, and the other side of the baking support plate 22 is provided with a first chute 221. A baking plate 3 is slidably connected, and four pairs of rotating surface-turning devices 2 are installed in the box body 1, and the four pairs of rotating surface-turning devices 2 are installed in a square array of two rows and two columns. The baking plate 3 i...

Embodiment 3

[0025] Embodiment 3: as Figure 1-Figure 4 As shown, a baking device for tea production includes a box body 1, and a hot air generator 11 is installed on the upper side of the bottom of the box body 1. The hot air generator 11 can adjust the air volume and air temperature according to needs, so it can be used according to the difference of tea baking. stage, adjust the required baking temperature, the inner side of the box body 1 is equipped with a rotary turning device 2, and the rotating turning device 2 is located at the top of the hot air generator 11. The rotary turning device 2 includes a first stepping motor 21, the first stepping motor 21 is installed on the inside of the side plate of the casing 1, the output end of the first stepping motor 21 is equipped with a baking support plate 22 on one side, and the baking support plate 22 is on the other side There is a first chute 221 on one side, and the rotating turning devices 2 are arranged oppositely. A baking plate 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com