Mechanical part precise grooving device

A precise technology for mechanical parts, applied in the field of precise slotting devices for mechanical parts, can solve problems such as the inability to accurately control the slotting depth, achieve the effects of improving slotting efficiency and slotting accuracy, simple structure, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

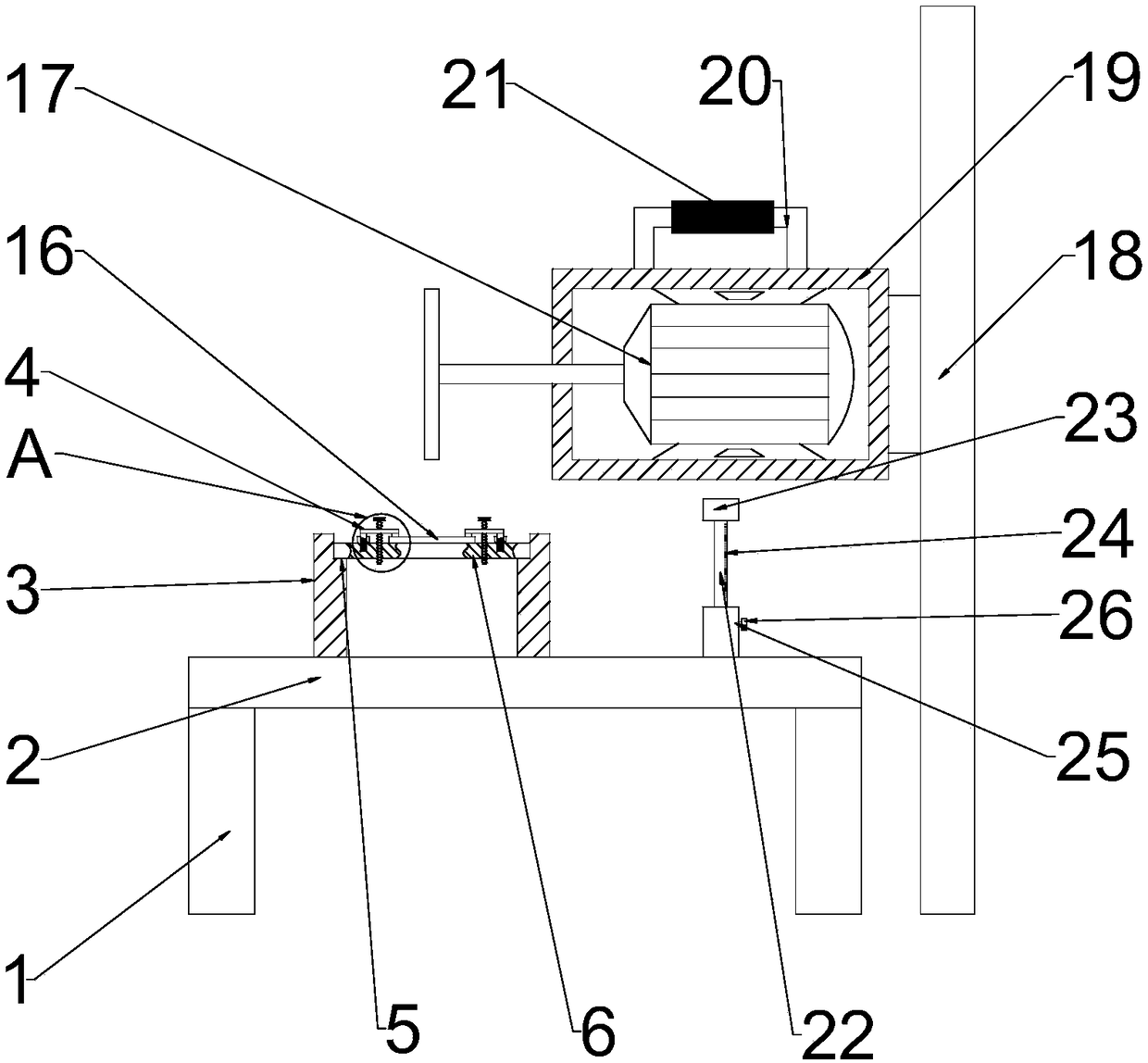

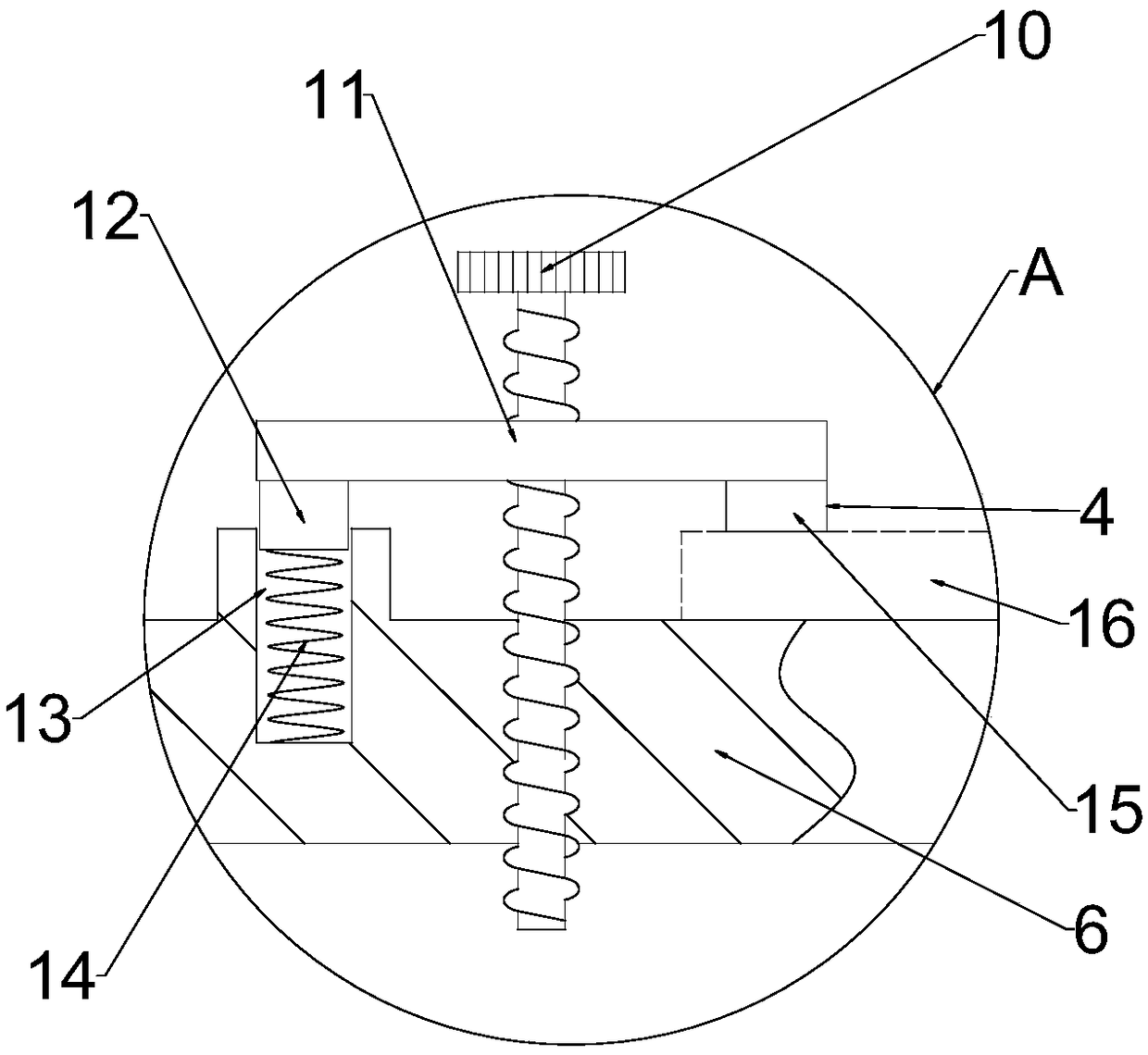

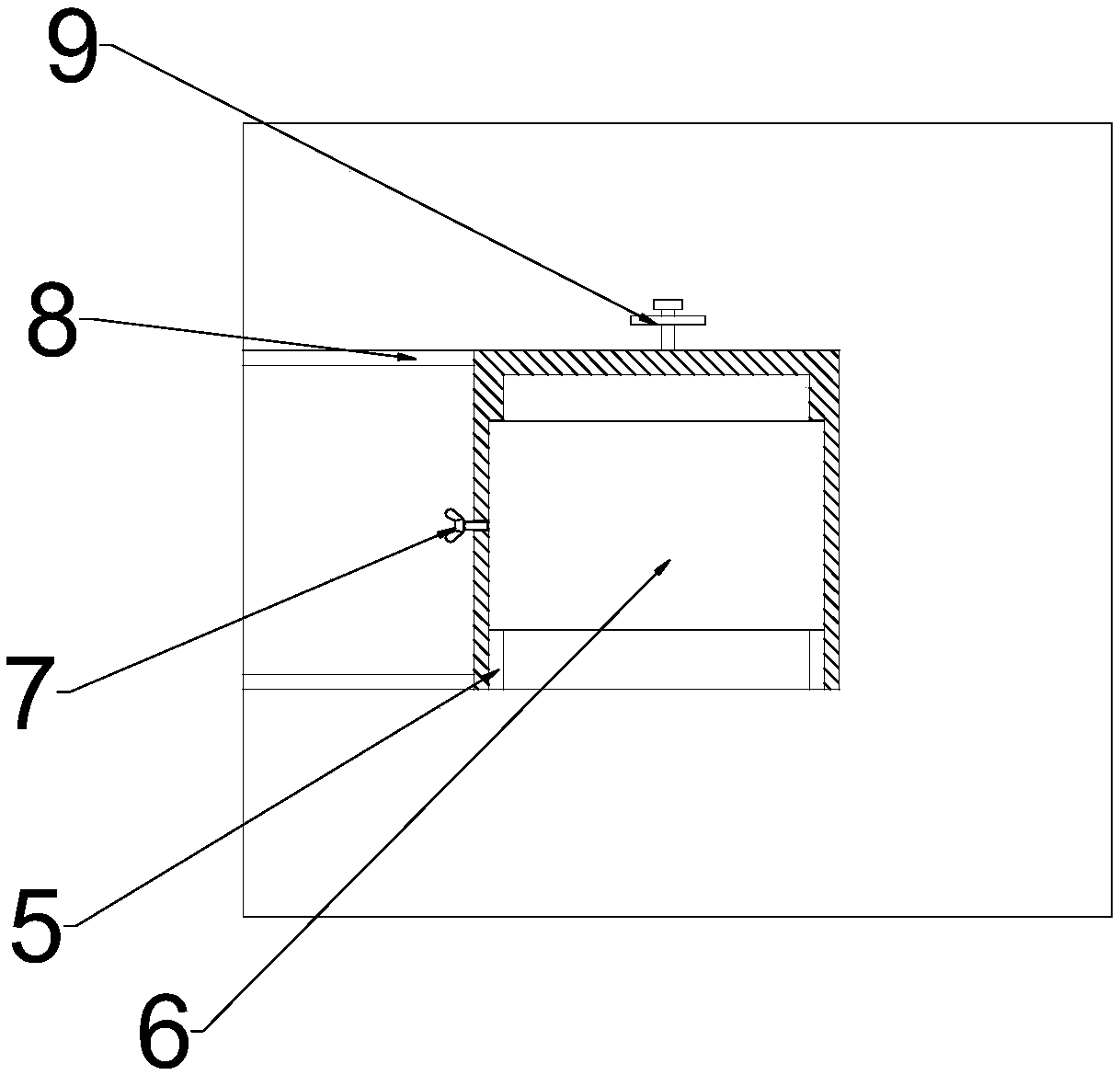

[0016] see figure 1 , figure 2 and image 3 , a precise slotting device for mechanical parts, including a frame 1, a desktop 2, a part 16 and a slotting machine 17, the frame 1 is welded and fixed on the bottom of the desktop 2, and the part 16 is fixed above the desktop 2, The slotting machine 17 is arranged above the part 16; the left and right chute 8 is processed on the upper surface of the desktop 2, and the fixed barrel 3 is slidably installed in the left and right chute 8, and the fixed barrel 3 is provided with The left and right fixing bolts 9 can adjust the position of the fixed barrel 3 in the left and right chutes 8 and fix the left and right chutes 8; the front and rear chutes 5 are processed on the fixed barrel 3, and the front and rear chutes 5 are The front and rear sliders 6 are slidingly installed, and the front and rear sliders 6 are fixed by the front and rear fixing bolts 7, so that the front and rear sliders 6 can slide and be fixed on the fixed bucket...

Embodiment 2

[0018] see Figure 4 , compared with Embodiment 1, the difference between Embodiment 2 and Embodiment 1 is that a buffer mechanism 27 is symmetrically arranged on the left and right sides of the bottom of the installation bucket 19, which plays a good buffer role and is used to protect the limit mechanism 22; the buffer mechanism 27 includes a casing 28, a buffer block 29 and a spring 30, the top of the casing 28 is close to the bottom of the installation bucket 19, the inner cavity of the spring 30 is slidably installed below the casing 28 and the bottom is tightly connected to the buffer block 29 paste.

[0019] The working principle of the present invention is: through described front and rear chute 5 and described left and right chute 8 can adjust the relative position of described parts 16 and described slotting machine 17, when described slotting machine 17 is positioned at described parts 16 For the position where slotting is required, the position of the part 16 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com