Glass digitalized etching method

A glass and glass plate technology is applied in the field of digital etching to manufacture glass back covers of organic electroluminescent display devices, so as to reduce the manufacturing cost and improve the etching efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

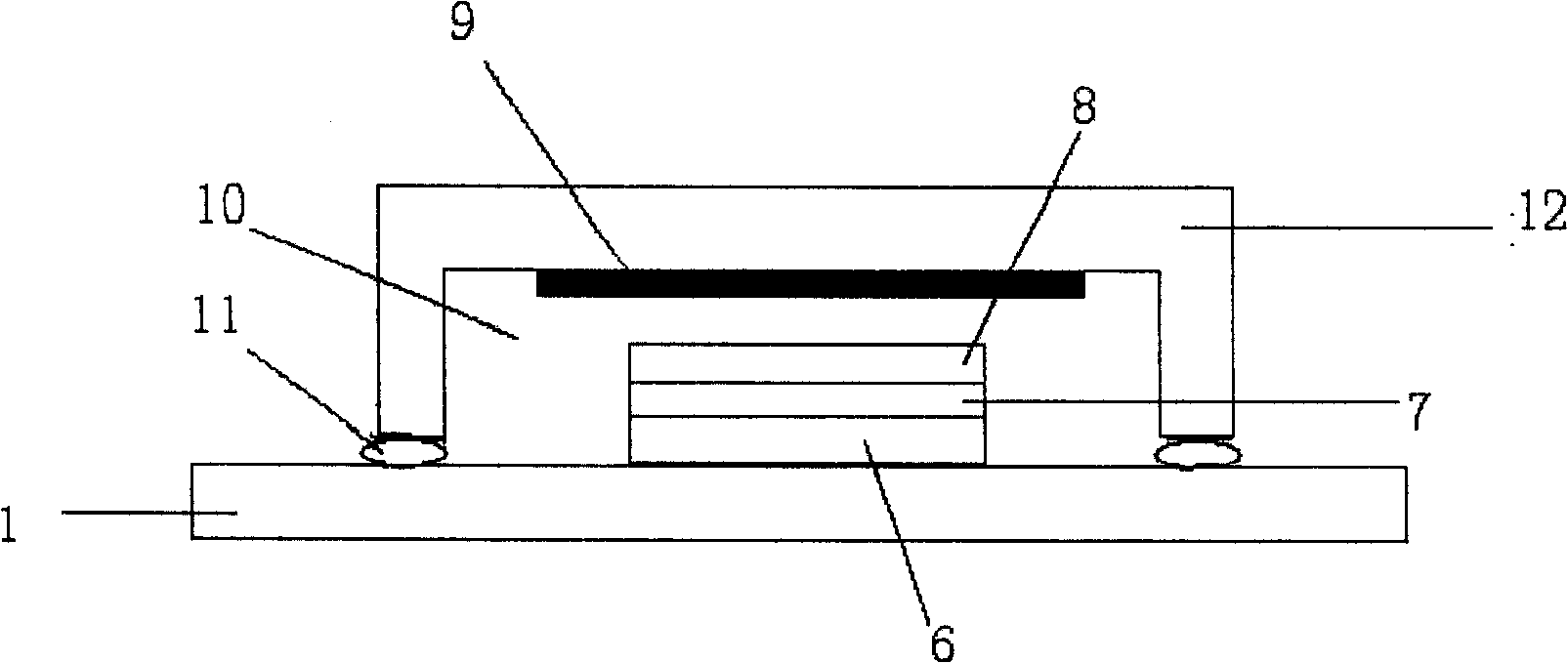

[0033] Below, with reference to the accompanying drawings, a further detailed description will be made on the glass rear cover of the organic electroluminescence display device manufactured by the present invention.

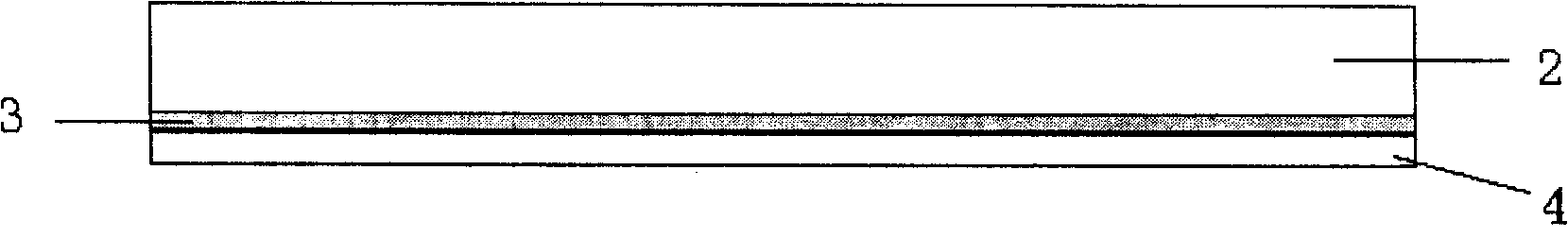

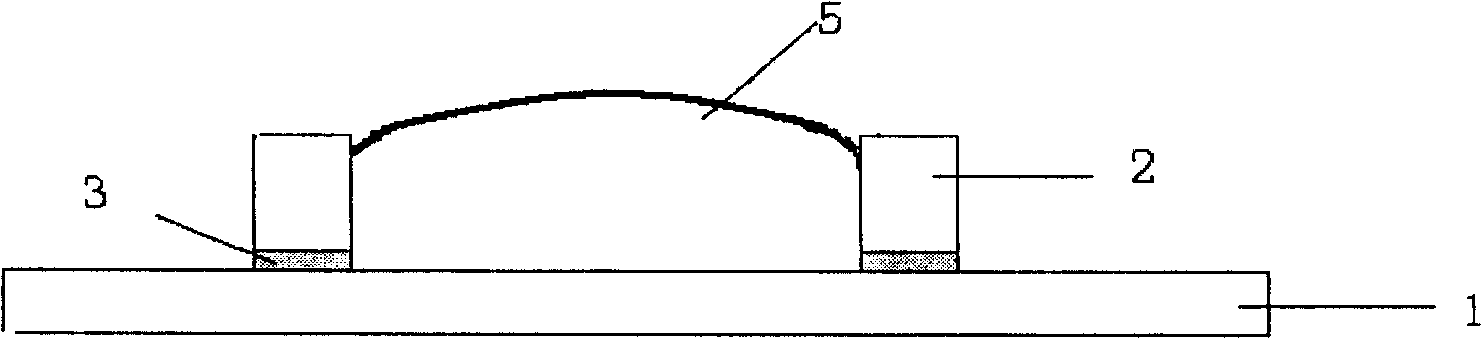

[0034] figure 1 As shown, the mask material used in the present invention generally includes a mask material 2, an adhesive surface 3 and a protective film 4, and the mask material 2 is a basic covering material for covering a glass plate surface that does not need to be etched; The adhesive surface 3 is used to tightly combine the mask material 2 and the glass plate 1, and there is no gap between the two; the protective film 4 is used to protect the adhesive surface 3 from being damaged when not in use. If it is damaged, when using the mask material 2, remove the protective film 4, align the adhesive surface 3 with the glass plate 1 to cover, and press the mask material 2 so that it is tightly covered on the glass plate 1, and the adhesive surface 3 The two ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com