Assembly device and method for automobile shock absorber assembly

An automobile shock absorber and assembly assembly technology, which is applied in the direction of assembly machines, metal processing equipment, metal processing, etc., can solve the problems of reduced installation accuracy of vibration isolation pads, uneven spring force, and low installation accuracy, so as to prevent The installation accuracy is reduced, the force of the spring is uniform, and the effect of improving the installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

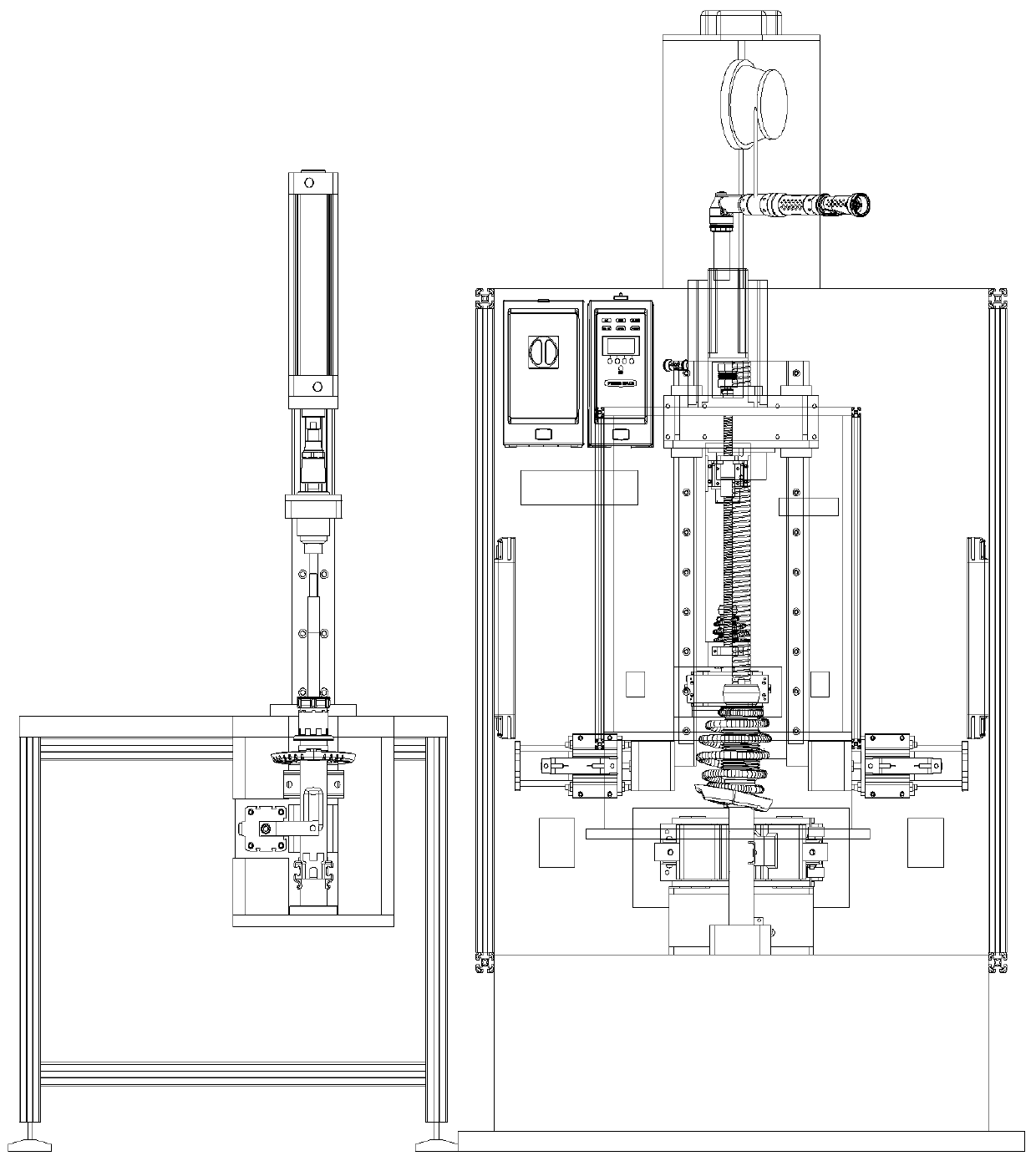

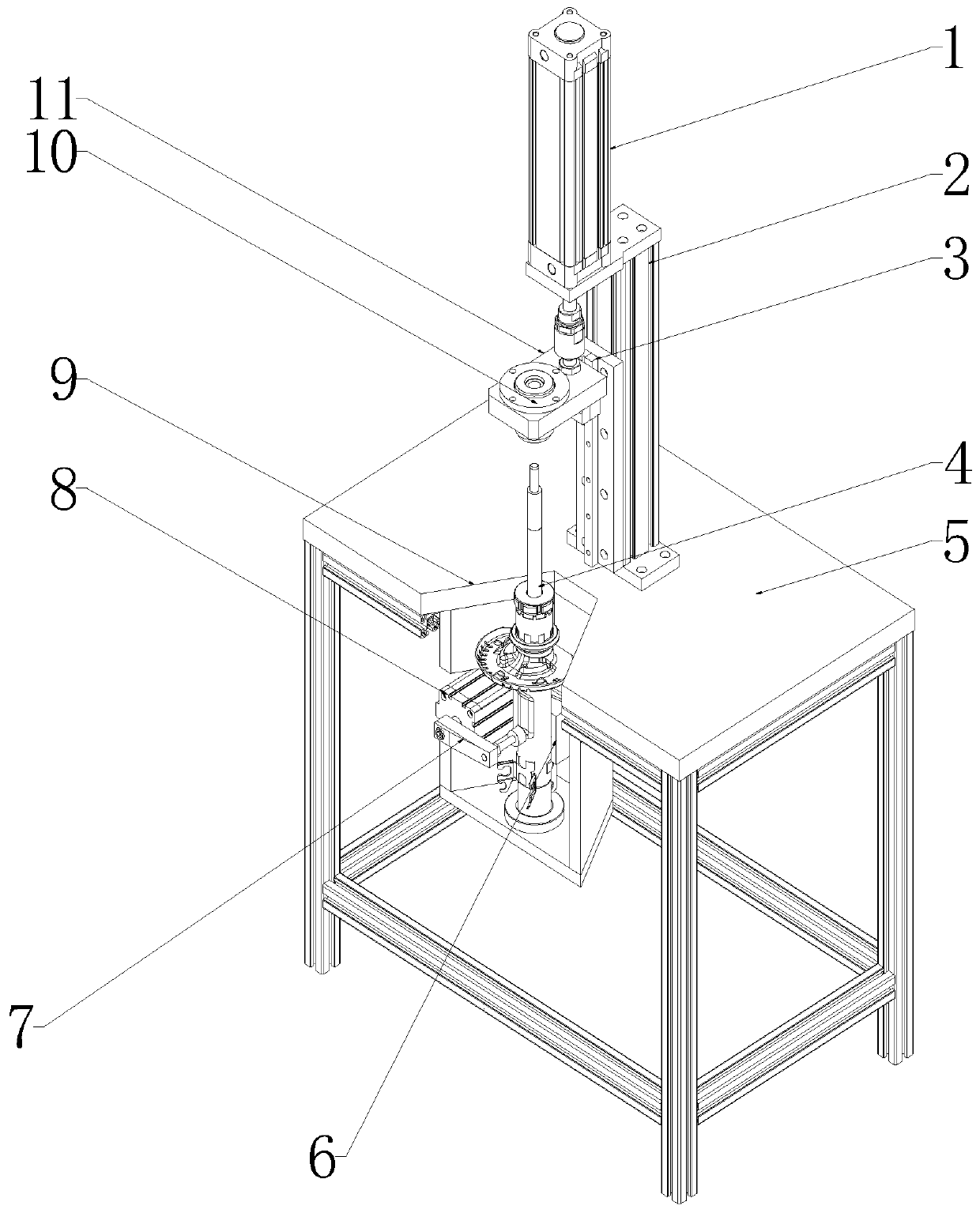

[0046] see Figure 1-5 , an automobile shock absorber assembly assembly device, characterized in that it includes a buffer block press-fitting device and an adjacent shock-absorbing pad press-fitting device, wherein

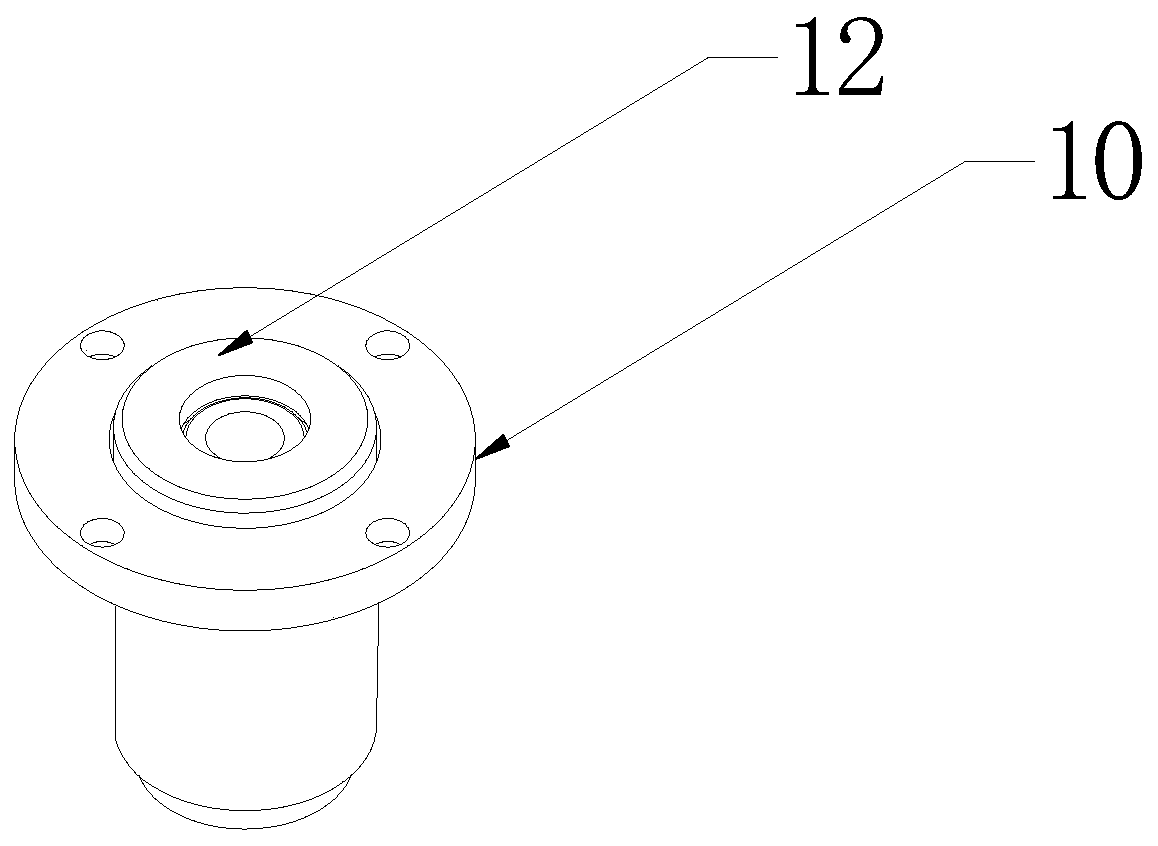

[0047] The buffer block press-fitting device includes a linear guide rail I2, which is vertically installed on the workbench 5, and a horizontal connecting plate is arranged above the linear guide rail I2, and a press-fitting cylinder 1 is vertically installed on the connecting plate, and a press-fitting cylinder 1 The piston rod is connected with a pressure plate 11, the back of the pressure plate 11 is connected with a slider I3, the slider I3 is installed on the linear guide rail I2, the pressure plate 11 can be pressed vertically downward under the action of the press cylinder 1, and the center of the pressure plate 11 has a The buffer block positioning sleeve 10, the buffer block can be plugged and fixed from the bottom of the buffer block positioning sleeve...

Embodiment 2

[0059] A method for assembling an automobile shock absorber assembly, which is applied to the equipment described in the above embodiments, includes the following steps:

[0060] S1: Insert the shock absorber assembly into the buffer block press-fitting device, and press and fix it through the pressing mechanism and positioning fixture 6;

[0061] S2: Install the buffer block into the buffer block positioning sleeve 10, and then press the buffer block through the pressing plate 11;

[0062] S3: Take out the shock absorber assembly from the buffer block press-fitting device, insert it into the support block 21 at the bottom of the shock-isolating pad press-fitting device, clamp and fix it with the claws 20, and then install the spring, bearing, spring pad and spring seat;

[0063] S4: The spring is straightened and fixed by the straightening mechanism, and the vibration isolation pad is put into the positioning sleeve 27 of the vibration isolation pad, and then press-fitted by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com