Casting burr removal device

A technology for cleaning devices and burrs, which is applied in spraying devices, grinding/polishing safety devices, and machine tools suitable for grinding the edge of workpieces, etc., and can solve the problem of not having real-time cleaning of waste and oiling protection, and waste scratching parts And oxidized parts, single structure and function, etc., to achieve the effect of reasonable design, cost saving and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

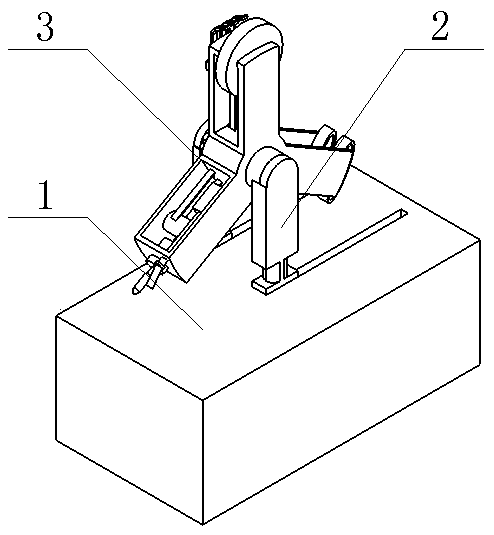

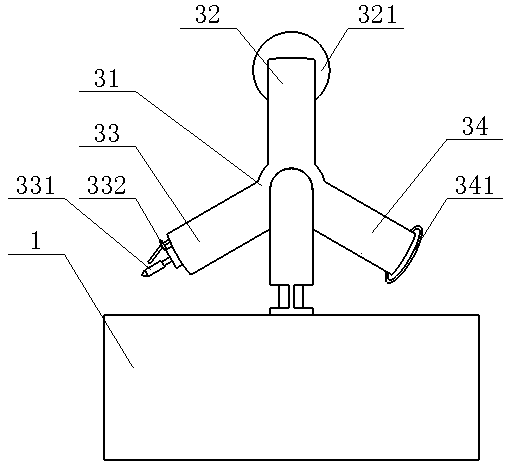

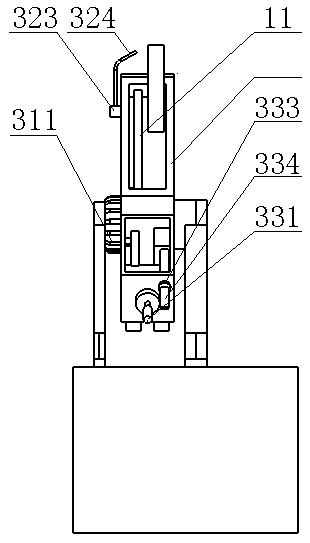

[0017] Such as Figure 1-4 As shown, the present invention is a casting burr cleaning device, which includes an operating table 1, a support rod 2 and a cleaning head 3. The operating table 1 is set as a square table to facilitate grinding and cleaning of castings. The upper end of the operating table 1 is provided with a chute 11. The chute 11 is two horizontal grooves, which are used to facilitate the sliding use of the support rod 2 on the upper end of the console 1. It is used to facilitate the placement of the console 1 when different castings are polished. The support rod 2 is set on the console 1. and the support rod 2 is slidingly connected with the console 1, the lower end of the support rod 2 is provided with a hydraulic lifting rod 21, the hydraulic lifting rod 21 is fixedly connected with the support rod 2, and the support rod 2 can move horizontally or vertically relative to the console Lifting greatly improves the position flexibility of the cleaning head 3, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com