Clamping device for filling vehicle shock absorber

A technology of automobile shock absorbers and clamping devices, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve problems such as simple and no structure, and achieve the effects of expanding the operating range, reducing placement time, and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

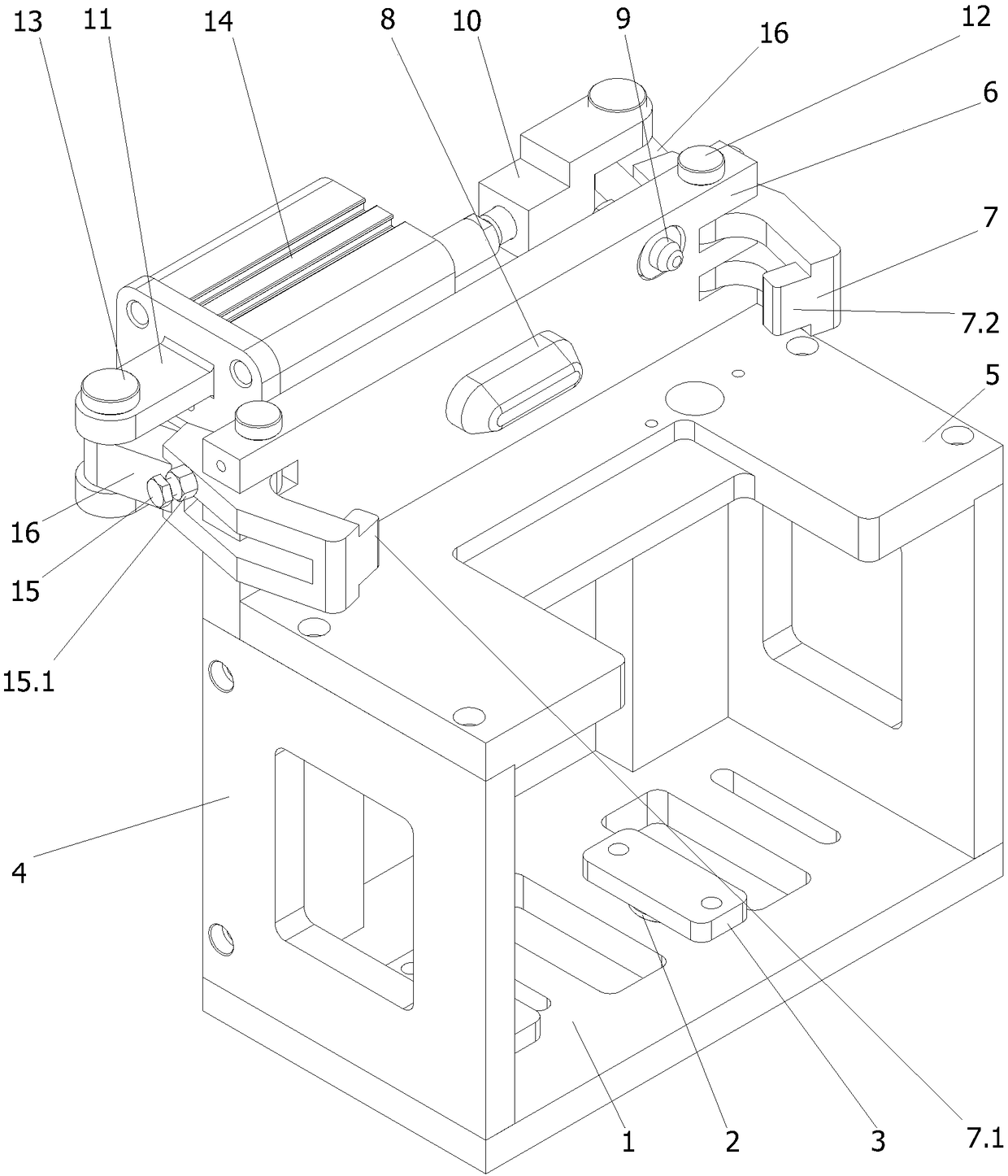

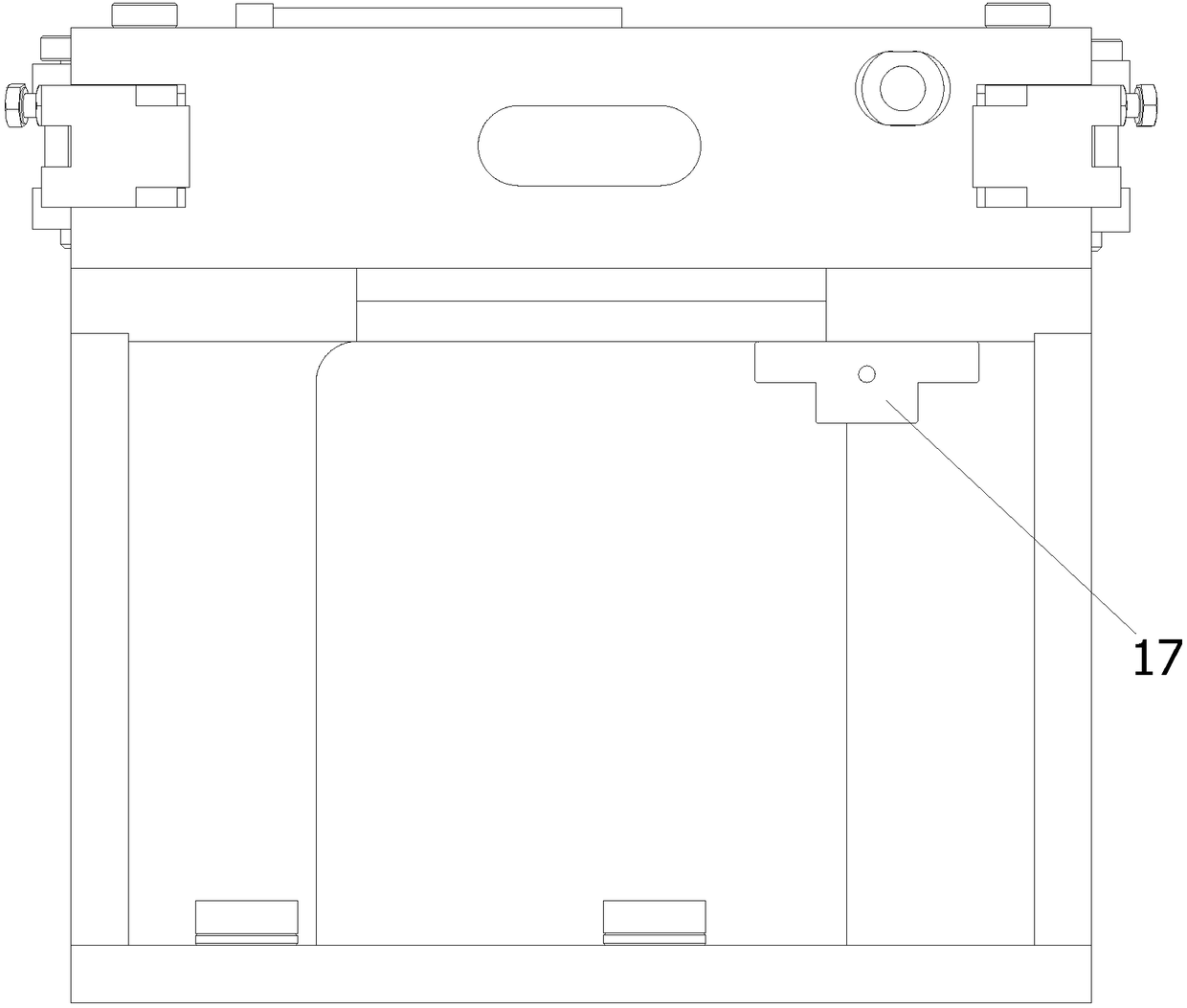

[0018] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0019] Such as figure 1 , figure 2 As shown, the present invention includes a base plate 1, a side vertical plate 4, a shock absorber support plate 5, a back plate 6, jaws 7, a cylinder connector 10, a cylinder fixing seat 11, a jaw rotating shaft 12, a connecting pin 13, and a cylinder 14 , Connecting arm 16. The cylinder body of the cylinder 14 links to each other with the cylinder holder 11, and the left and right ends of the cylinder 14 are respectively provided with a piston. The side vertical plate 4 includes two left and right side vertical plates, the lower end of the left vertical plate is fixedly connected with the left end of the base plate 1, and the lower end of the right vertical plate is fixedly connected with the right end of the base plate 1, and both are not shown in the figure. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com