Operating table for electronic product maintenance

A technology for electronic products and operating consoles, applied in workbenches, manufacturing tools, etc., can solve the problems of poor fixed storage effect of small parts, easy rolling of small parts, and poor effect of electrostatic diversion of the human body, so as to be easy to find and repair. Use, easy to find and assemble, the effect of saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

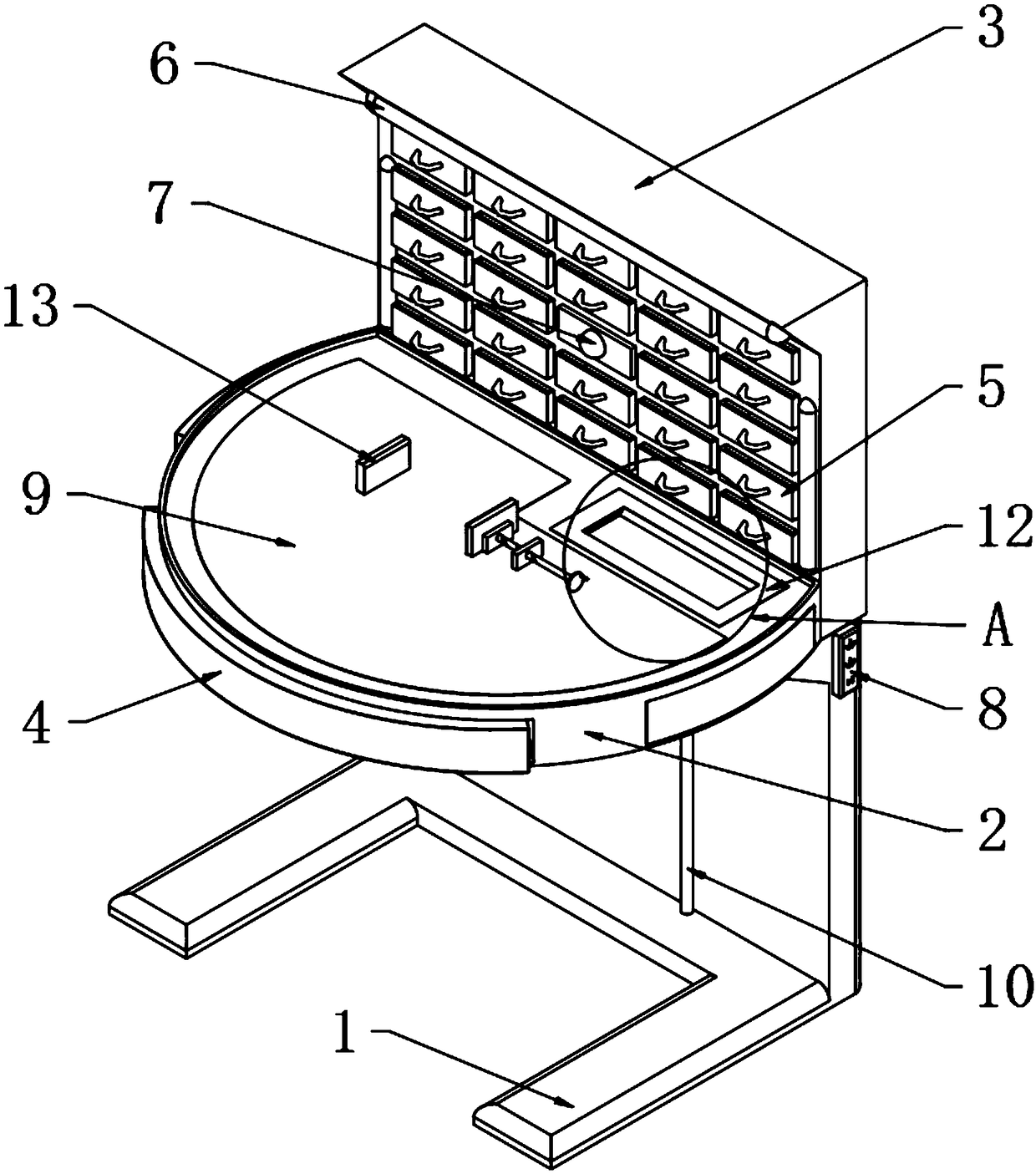

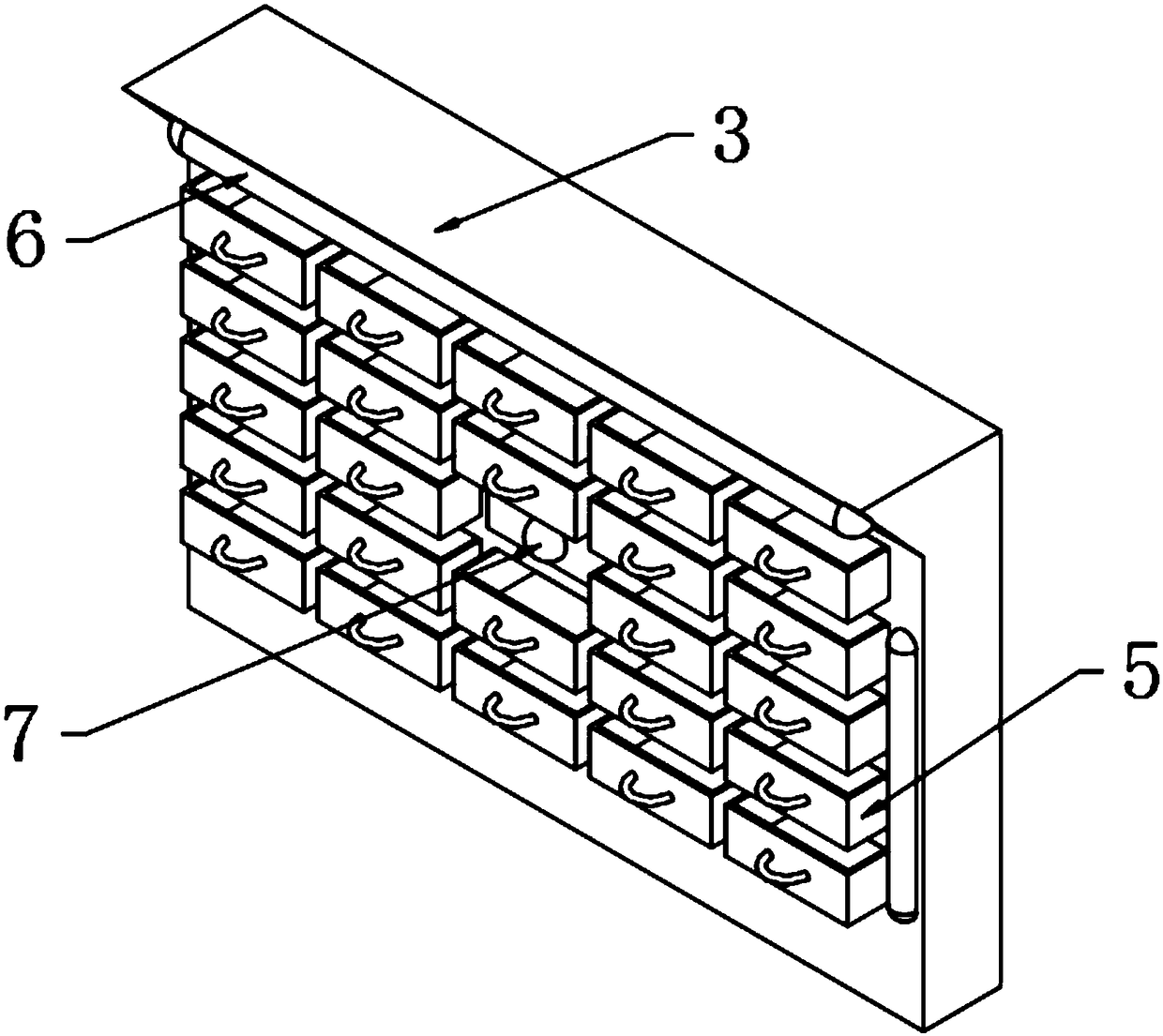

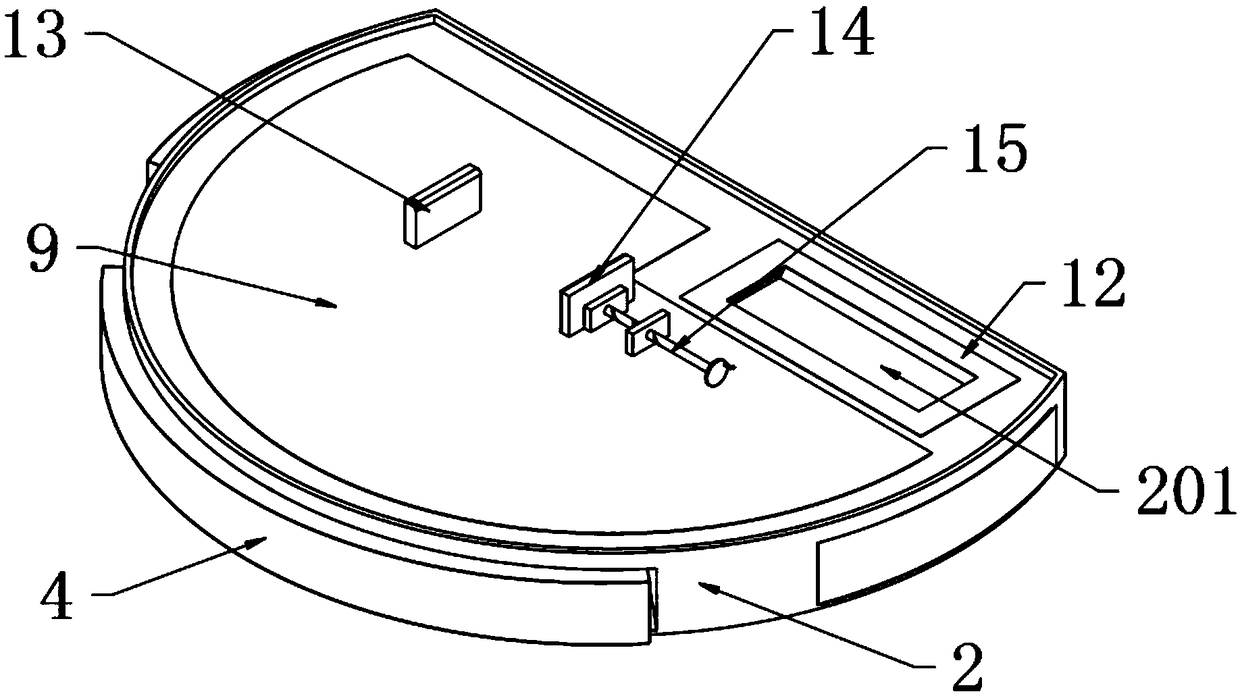

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The invention provides an operation console for electronic product maintenance, including a base 1, an operation console 2, a storage slot 201, a rear stopper 3, a fan-shaped drawer 4, a small drawer 5, a lighting lamp 6, an infrared sensor switch 7, and a power socket 8. Copper sheet 9, conductive wire 10, magnetic bar 11, white plastic sheet 12, left stopper 13, right stopper 14 and threaded shaft 15, the rear end of the bottom of the console 2 is installed on the top end surface of the base 1, and The bottom end surface of the rear block 3 is installed on the top end surface of the base 1; the rear end surface of the operating table 2 is fitted with the bottom of the front end of the rear block 3; the fan-shaped drawer 4 is installed inside the operating table 2, and the operating table 2 is Circular block structure; the small drawer 5 is placed on the back block 3; the infrared sensor switch 7 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com