Shunting-type deodorization system and fecal suction truck

A shunt type and valve technology, applied in separation methods, dispersed particle separation, biological sludge treatment, etc., can solve the problems of deodorizing liquid sucking back, and achieve the effect of preventing odor overflow and avoiding sucking back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

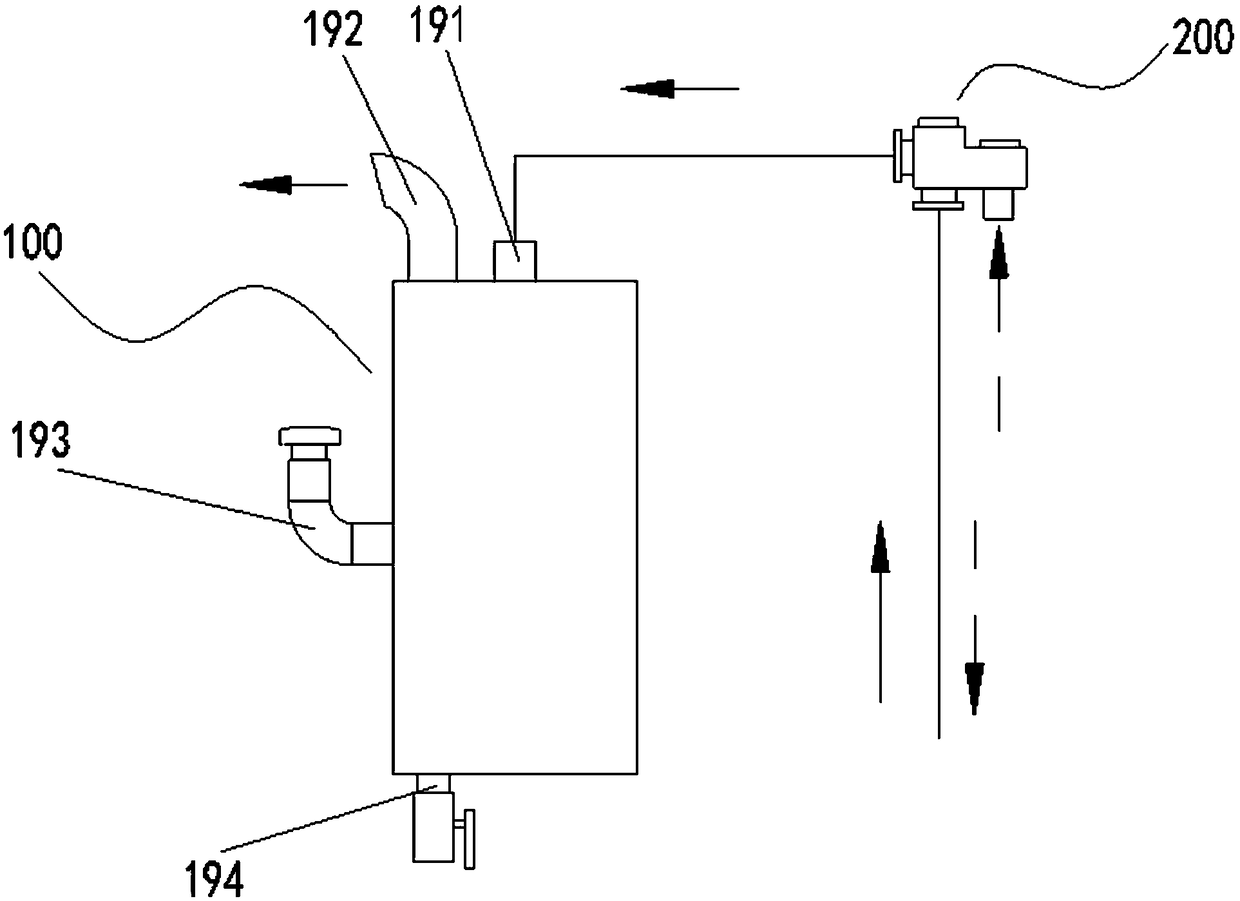

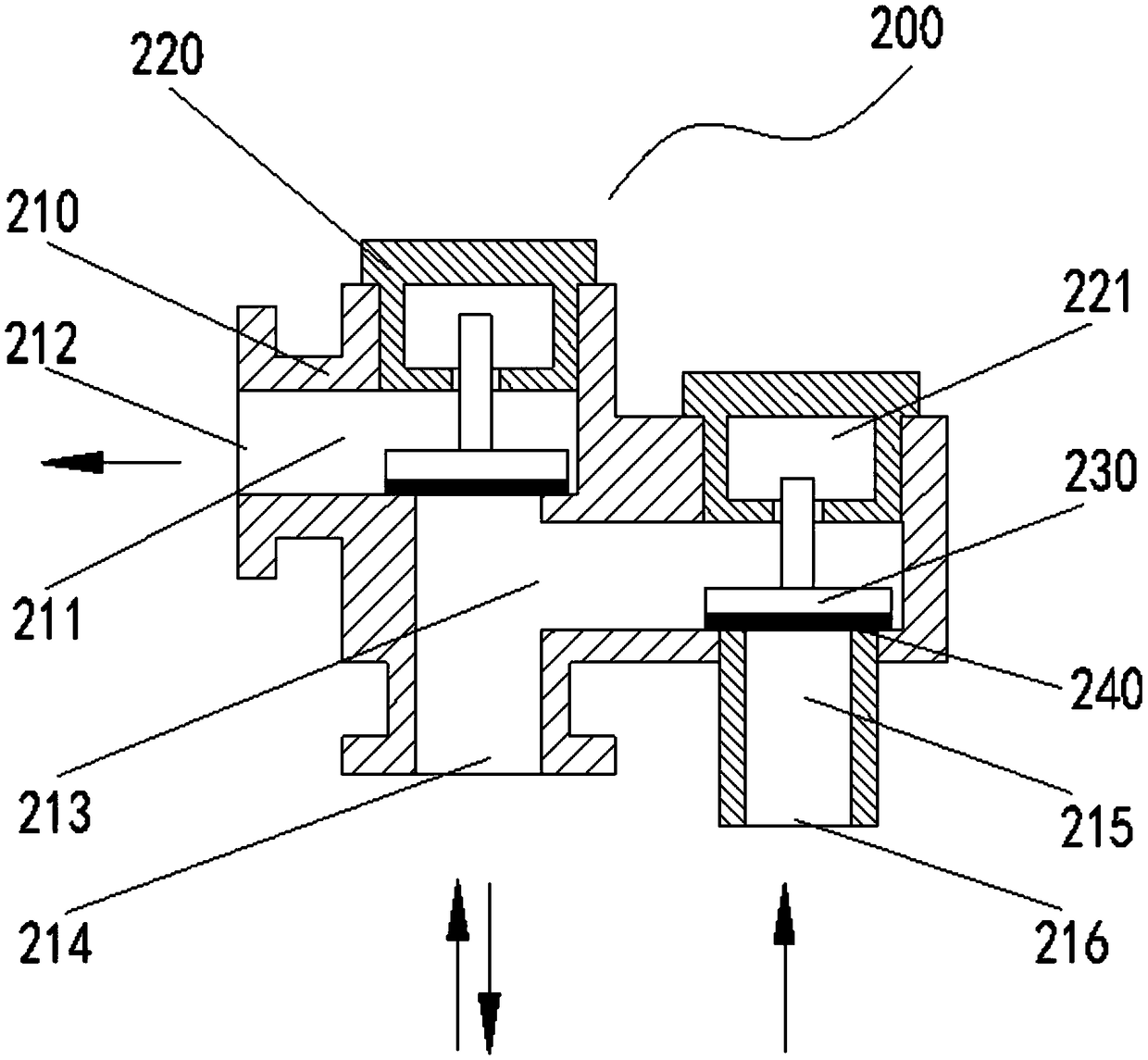

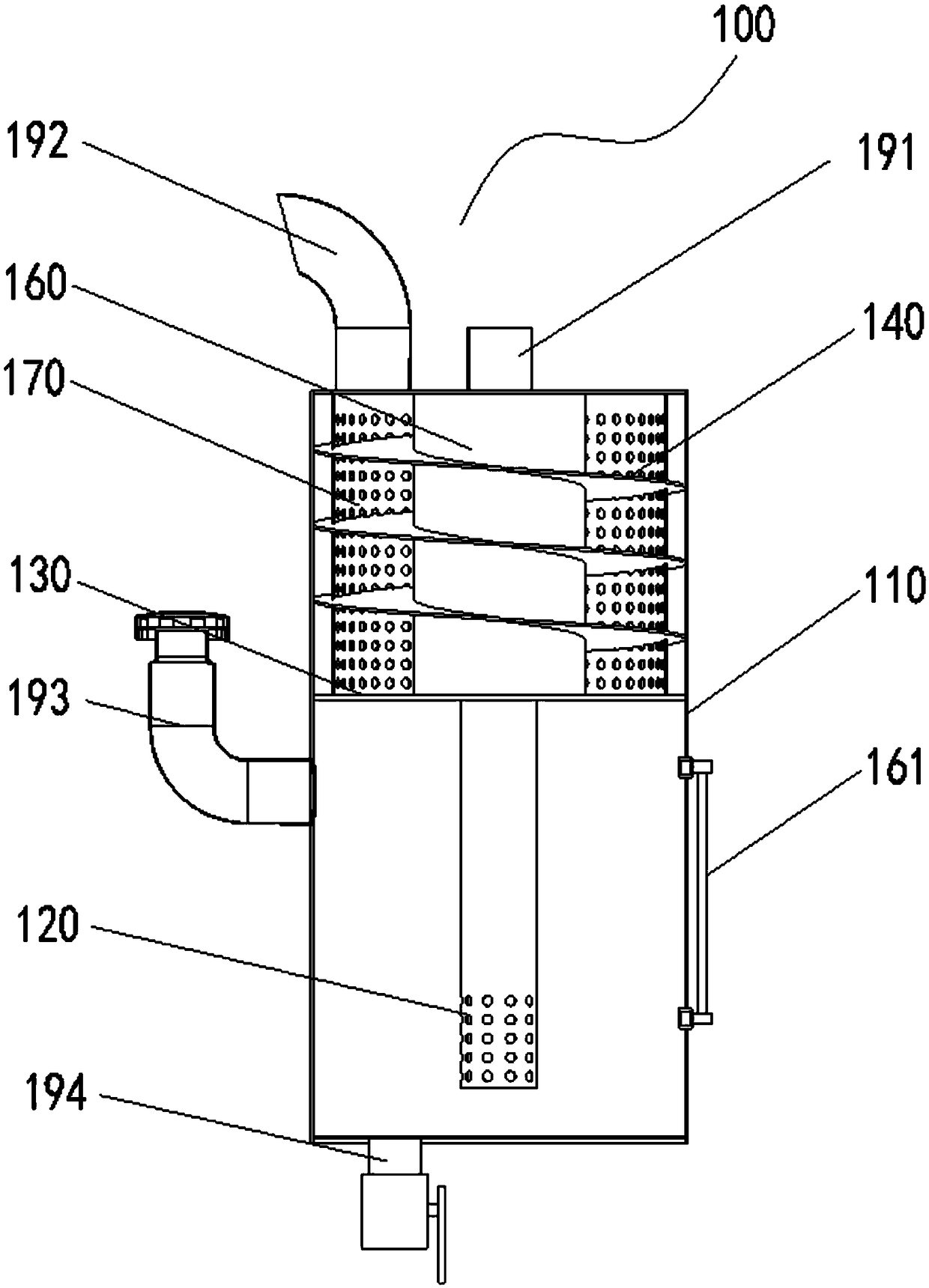

[0041] Please also refer to Figure 1 to Figure 5 , the present invention provides a split deodorization system, the split deodorization system includes a deodorization mechanism 100, a self-controlled vent valve 200 and a gas delivery mechanism 300, the self-controlled vent valve 200 includes a body 210, a first The valve and the second valve, the body 210 has an exhaust cavity 211, an alternate air cavity 213 and an intake cavity 215 connected in sequence, the exhaust cavity 211 leads to the exhaust port 212, and the alternate air cavity 213 leads to Alternate air port 214, the air inlet chamber 215 leads to the air inlet port 216, the first valve is arranged on the communication port between the alternate air chamber 213 and the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com