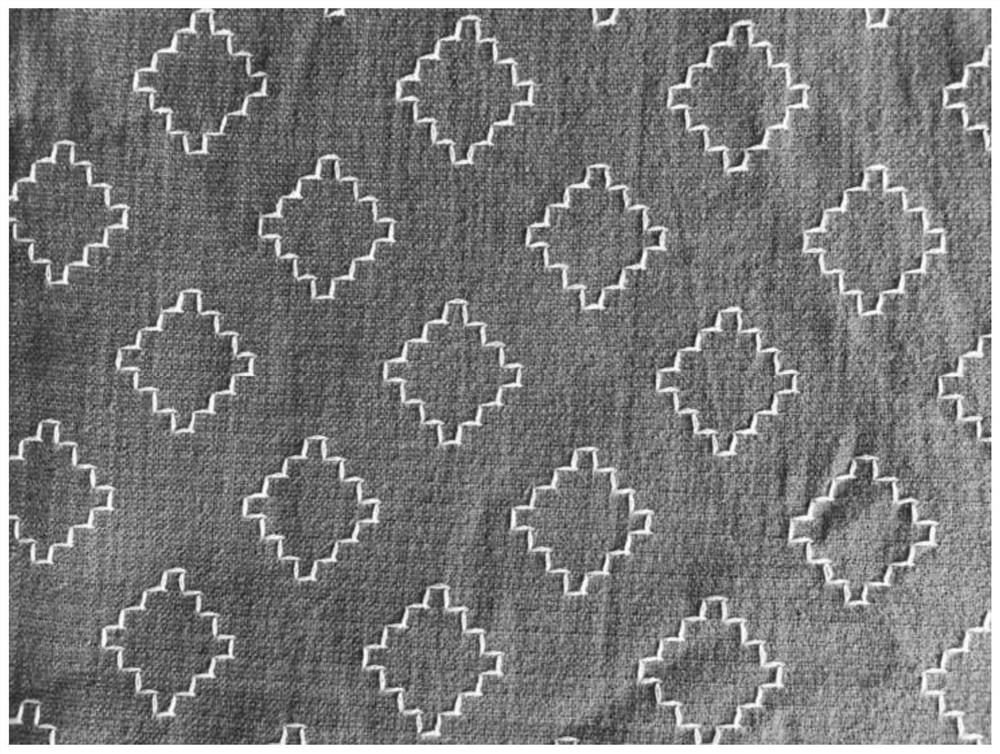

Embedded soft line drawing towel and its weaving process

A towel and flexible technology, applied in textiles, papermaking, textiles, fabrics, etc., can solve the problems of uneven weft density, which can only be expressed in local parts of the product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Yarn and production equipment requirements:

[0036]Yarn selection: yarn material is 100% cotton; wool warp yarn 18.2tex×2 weakly twisted yarn, bottom ground warp yarn and clamping ground warp yarn are 14.6tex×2, clamping weft yarn and raised weft yarn are 36.4tex and 29.2tex respectively, The textured ground warp and textured weft are 18.2tex×2 weakly twisted yarns; the reed number is 64#, and the weft density is 48 picks / 2.54cm.

[0037] The twist of weak twist yarn is 33 twists / 10cm.

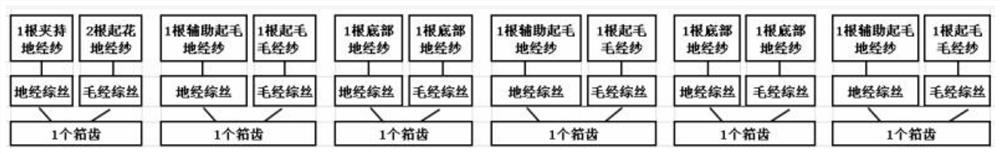

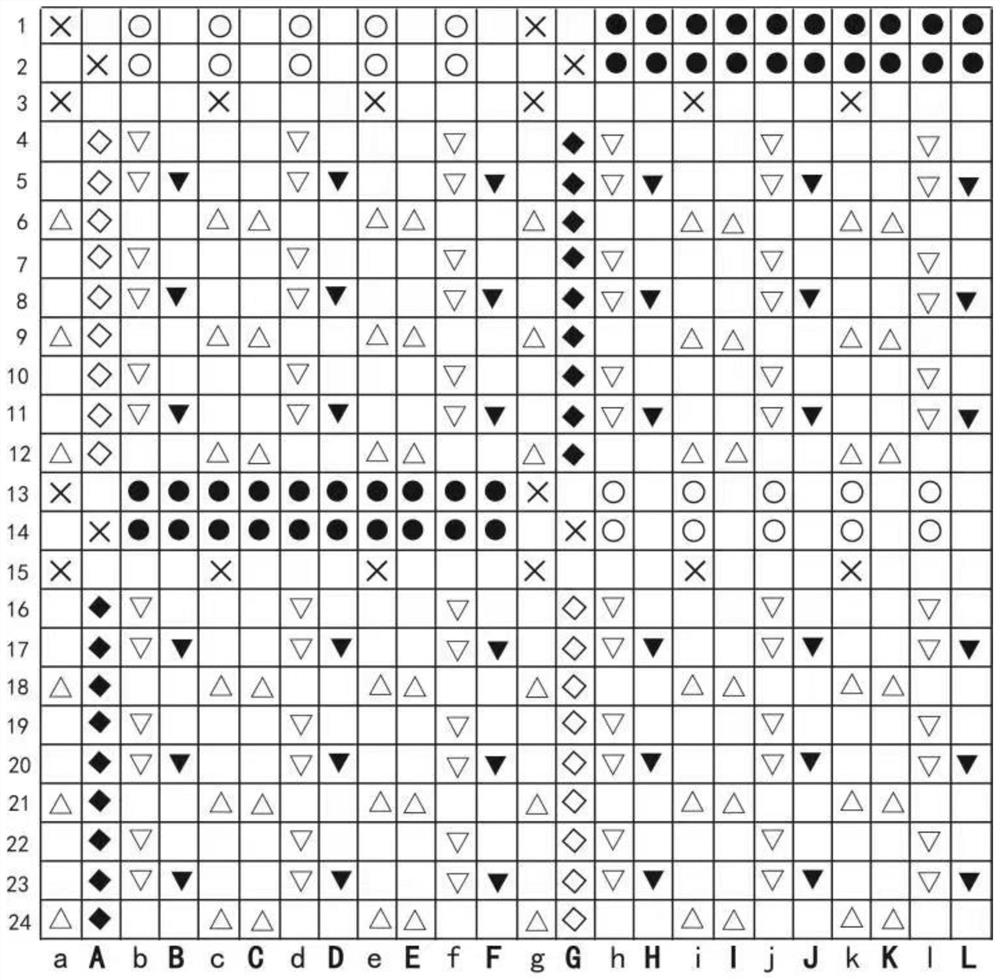

[0038] Use as attached figure 1 The way of drafting: one warp weaving cycle is 10 ground warp yarns, 3 wool warp yarns, including 2 raised ground warp yarns, 1 clamping ground warp yarn, 3 auxiliary raised ground warp yarns and 3 wool warp yarns, and 4 bottom ground warp yarns Warp yarn; the heald drawing sequence is: 1 clamping ground warp yarn penetrates 1 ground warp heddle, 2 raised ground warp yarns penetrates into wool warp heddle, and the upper part penetrates into a reed toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com