Carbon fiber and basalt fiber weaving process

A basalt fiber and carbon fiber weaving technology, which is applied in the field of textile weaving, can solve the problems of reduced fiber volume content, no lateral movement, and reduced product performance, achieving high tension, increased contact surface, and less prone to snagging and pilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

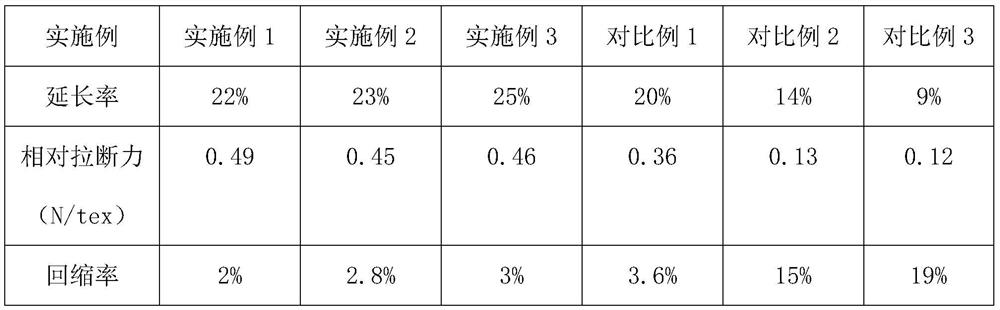

Examples

Embodiment 1

[0025] A carbon fiber and basalt fiber weaving process, comprising the following steps:

[0026] 1), making carbon fiber filaments, using nano-scale glass filaments as the inner core, then wrapping 15D / 1F polyester filament spinning equipment on the nano-scale carbon fiber filaments, and controlling the tension of the polyester filaments at 1.2 grams to produce a twist of 1500T / M, carbon fiber filament with draft ratio set to 2.0;

[0027] 2) For the production of basalt fiber yarn, take basalt fiber as the inner core, and then wrap the nylon yarn and spandex yarn as the outer yarn on the basalt fiber according to two different spiral directions of positive and negative through a high-speed wrapping machine to produce twist 2000T / M, flat basalt fiber filament with draft ratio set to 3.0;

[0028] 3), weaving, using basalt fiber as warp, carbon fiber as weft, warp is a three-layer structure, warp is combined in pairs, and warp monofilament is also arranged between two weft mon...

Embodiment 2

[0034] A carbon fiber and basalt fiber weaving process, comprising the following steps:

[0035] 1), making carbon fiber filaments, using nano-scale carbon fibers as the inner core, and then wrapping 15D / 1F polyester filament spinning equipment on the nano-scale carbon fiber filaments, and controlling the tension of the polyester filaments at 1.6 grams to produce a twist of 1800T / M, carbon fiber filament with draft ratio set to 2.5;

[0036] 2) For the production of basalt fiber yarn, carbon fiber is used as the inner core, and then the nylon yarn and spandex yarn used as the outer yarn are wrapped on the basalt fiber according to two different spiral directions of positive and negative through a high-speed wrapping machine, and the twist is produced. 2400T / M, flat basalt fiber filament with draft ratio set to 3.5;

[0037] 3) Weaving, using basalt fiber as the warp and carbon fiber as the weft, the warp is a three-layer structure, and the warp is combined in pairs; the first...

Embodiment 3

[0041] A carbon fiber and basalt fiber weaving process, comprising the following steps:

[0042] 1) The production of carbon fiber filaments, using nano-scale carbon fiber filaments as the inner core, and then wrapping 15D / 1F polyester filaments on the nano-scale carbon fiber filaments, and controlling the tension of the polyester filaments at 1.4 grams to produce a twist The carbon fiber filament is 1600T / M, and the draft ratio is set to 2.5;

[0043] 2) For the production of basalt fiber yarn, take basalt fiber as the inner core, and then wrap the nylon yarn and spandex yarn as the outer yarn on the basalt fiber according to two different spiral directions of positive and negative through a high-speed wrapping machine to produce twist 2200T / M, flat basalt fiber filament with draft ratio set to 3.5;

[0044] 3) Weaving, using basalt fiber as the warp, carbon fiber as the weft, and the warp as a three-layer structure; the first layer of warp combination combines the two longi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| draft ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com