Antibacterial breathable cut-resistant and stab-resistant fabric and production method thereof

A production method and cutting-resistant technology, applied in chemical instruments and methods, layered products, biochemical fiber treatment, etc., can solve problems such as affecting the scope of use, poor antibacterial air permeability, etc., to improve antistatic performance, improve air permeability, excellent Anti-friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

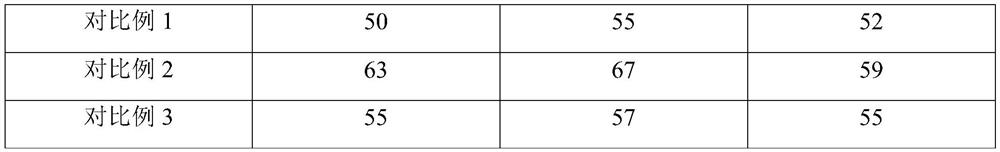

Examples

Embodiment 1

[0030]An antibacterial, breathable, cut-resistant and stab-resistant fabric, comprising interwoven antibacterial fabric layer silk threads and cut-proof and stab-resistant fabric layer silk threads, the antibacterial fabric layer silk threads are made of PET polyester fiber and antibacterial polyester fiber according to the mass fraction ratio of 4 :7 blended, the cut-resistant and stab-resistant fabric layer silk is made of ultra-high molecular weight polyethylene fiber, carbon fiber, cotton fiber and glass fiber according to the mass fraction ratio of 5:2:1:1; among them, PET polyester fiber and Silver-carrying antibacterial agent is sprayed on the spinning of antibacterial polyester fiber after blending, and antistatic agent is coated on ultra-high molecular weight polyethylene curly fiber.

[0031] A method for producing an antibacterial, breathable, cut-proof and stab-proof fabric, comprising the following steps:

[0032] A. Manufacture of antibacterial fabric layer silk ...

Embodiment 2

[0039] An antibacterial, breathable, cut-resistant and stab-resistant fabric, comprising interwoven antibacterial fabric layer silk threads and cut-proof and stab-resistant fabric layer silk threads, the antibacterial fabric layer silk threads are made of PET polyester fiber and antibacterial polyester fiber according to the mass fraction ratio of 4 :7 blended, the cut-resistant and stab-resistant fabric layer silk is made of ultra-high molecular weight polyethylene fiber, carbon fiber, cotton fiber and glass fiber according to the mass fraction ratio of 5:2:1:1; among them, PET polyester fiber and Silver-carrying antibacterial agent is sprayed on the spinning of antibacterial polyester fiber after blending, and antistatic agent is coated on ultra-high molecular weight polyethylene curly fiber.

[0040] A method for producing an antibacterial, breathable, cut-proof and stab-proof fabric, comprising the following steps:

[0041] A. Manufacture of antibacterial fabric layer silk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com