Air inlet device for drying drum of asphalt concrete mixing station in plateau area

A technology for a concrete mixing station and an air inlet device, which is applied in the directions of roads, road repairs, roads, etc., can solve the problems of insufficient internal oxygen supply, decreased drying effect, and damage caused by suffocation during drying, so as to prevent the front and rear movement, Prevent suffocation damage and ensure the effect of alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

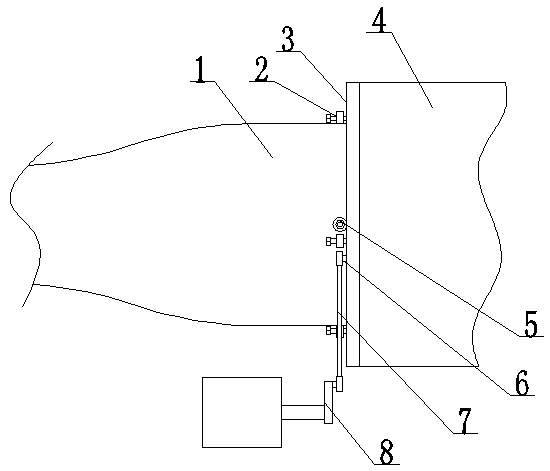

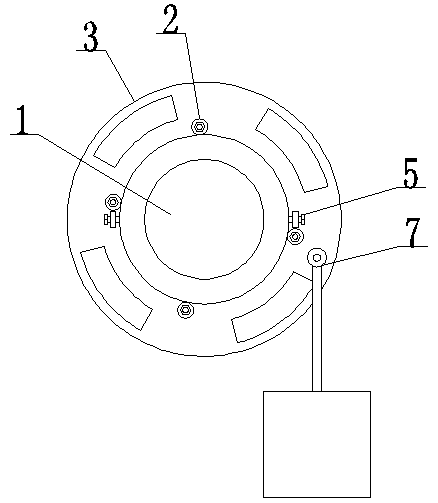

[0020] An air inlet device for a drying cylinder of an asphalt concrete mixing station in a plateau area, which consists of: an air inlet cylinder 1 and a drying cylinder 4, the air inlet cylinder of the dryer can move back and forth, and the air inlet cylinder is directed toward the Push forward to make the rotating disk fit the drying cylinder. The rotating disk 3 is set on the air inlet cylinder. A group of horizontal stoppers 2 evenly arranged on the circumference are arranged on the rotating disk. The bearing fits with the side wall of the air inlet, and the side wall of the air inlet is provided with a group of vertical stoppers 5 evenly arranged on the circumference, and the bearing of the vertical stopper fits with the rotating disk. The fixed pin 6 on the rotating disk is hinged with one end of the pull rod 7, and the other end of the pull rod is hinged with the rotating rod on the motor 8. By starting the motor, the pull rod is pulled down, thereby driving the rotatio...

Embodiment 2

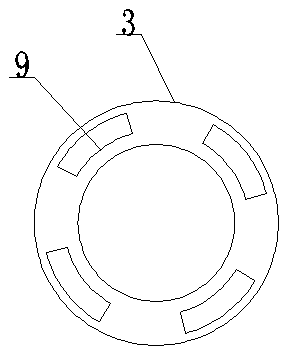

[0022] According to the air inlet device of the drying cylinder of the asphalt concrete mixing station in the plateau area described in Example 1, the rotating disk has four fan-shaped openings 9, and the inner wall of the drying cylinder has four fan-shaped openings corresponding to the fan-shaped openings. fan blade 10.

Embodiment 3

[0024] According to the air inlet device of the drying cylinder of the asphalt concrete mixing station in the plateau area described in embodiment 1 or 2, both the horizontal stopper and the vertical stopper are composed of fixed shafts, bearings and nuts, The bearing is sleeved on the fixed shaft, and one end of the fixed shaft is threadedly connected with the nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com