Disk surface flatness detection device of large polishing machine, and working method thereof

A flatness detection and polishing disc technology, which is applied to measuring devices and instruments, can solve the problems of high cost and difficulty in ensuring the movement accuracy of the probe, and achieve the effect of easy loading and unloading, saving manpower and time costs for disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiment of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings, but the specific embodiment of the present invention is only illustrative rather than restrictive. Processes and ideas, or directly or indirectly used in other related fields, are equally included in the scope of patent protection of the present invention.

[0043] The left and right directions of the present invention are only for describing aspects relative to the drawings, and do not constitute limitations on the present invention.

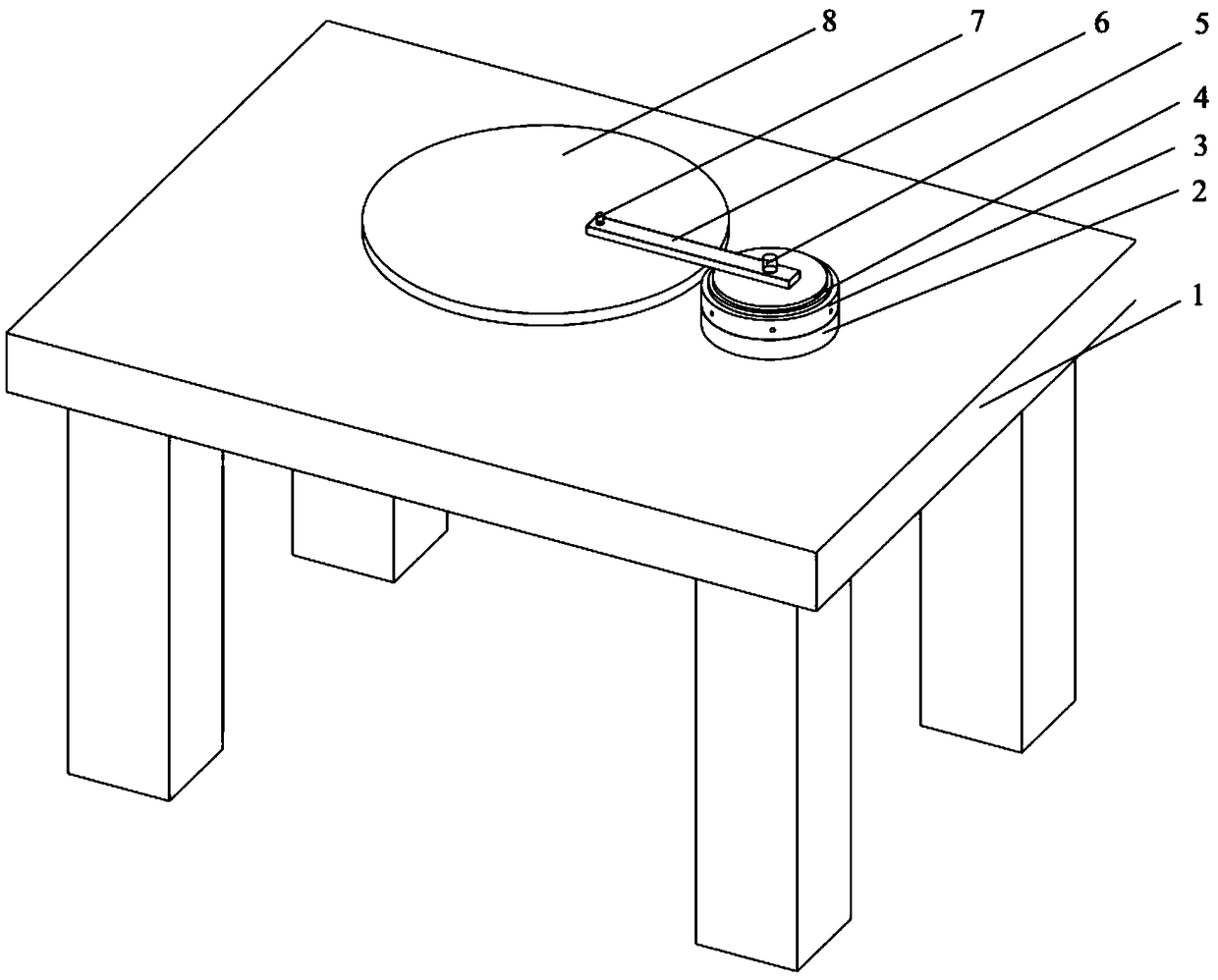

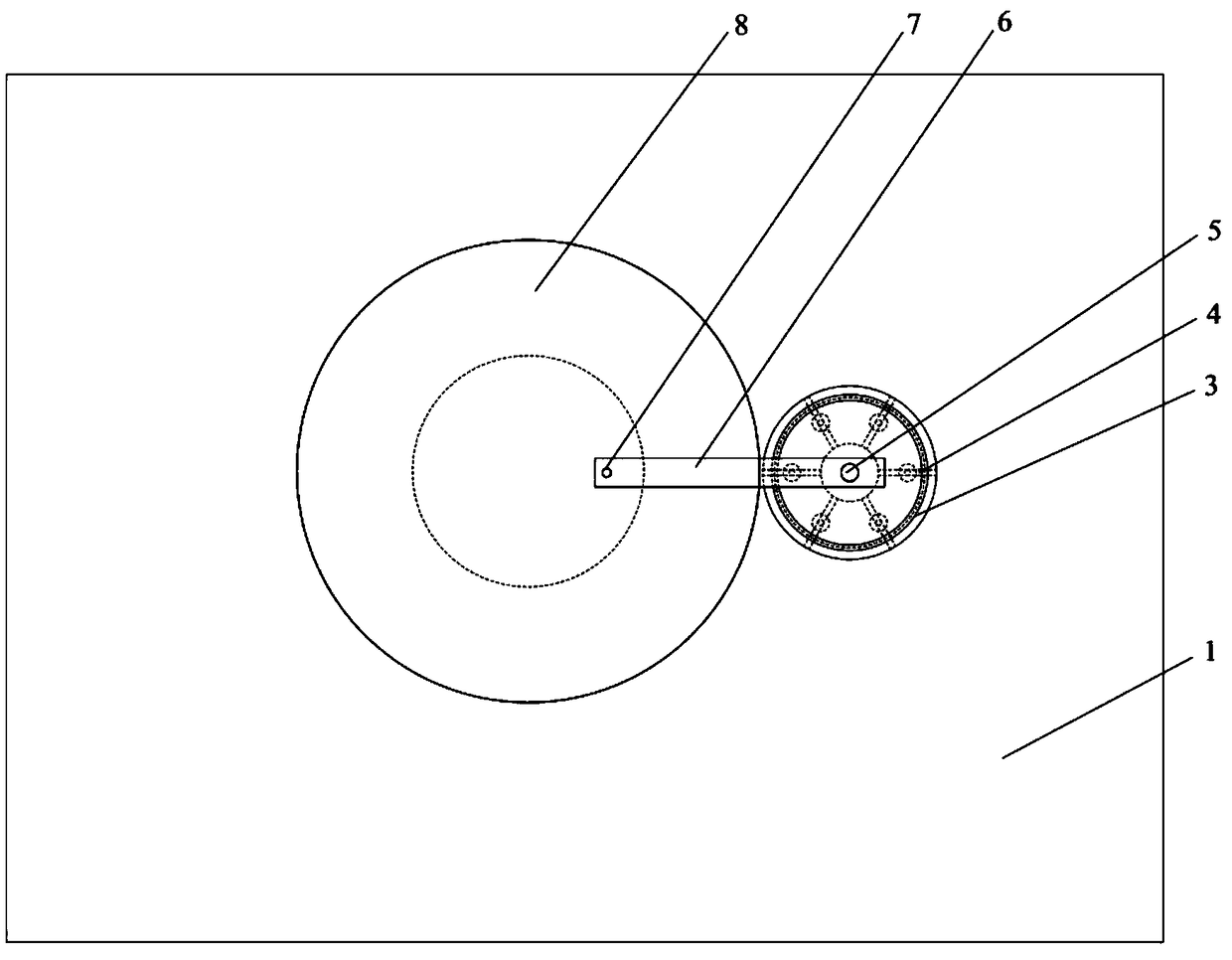

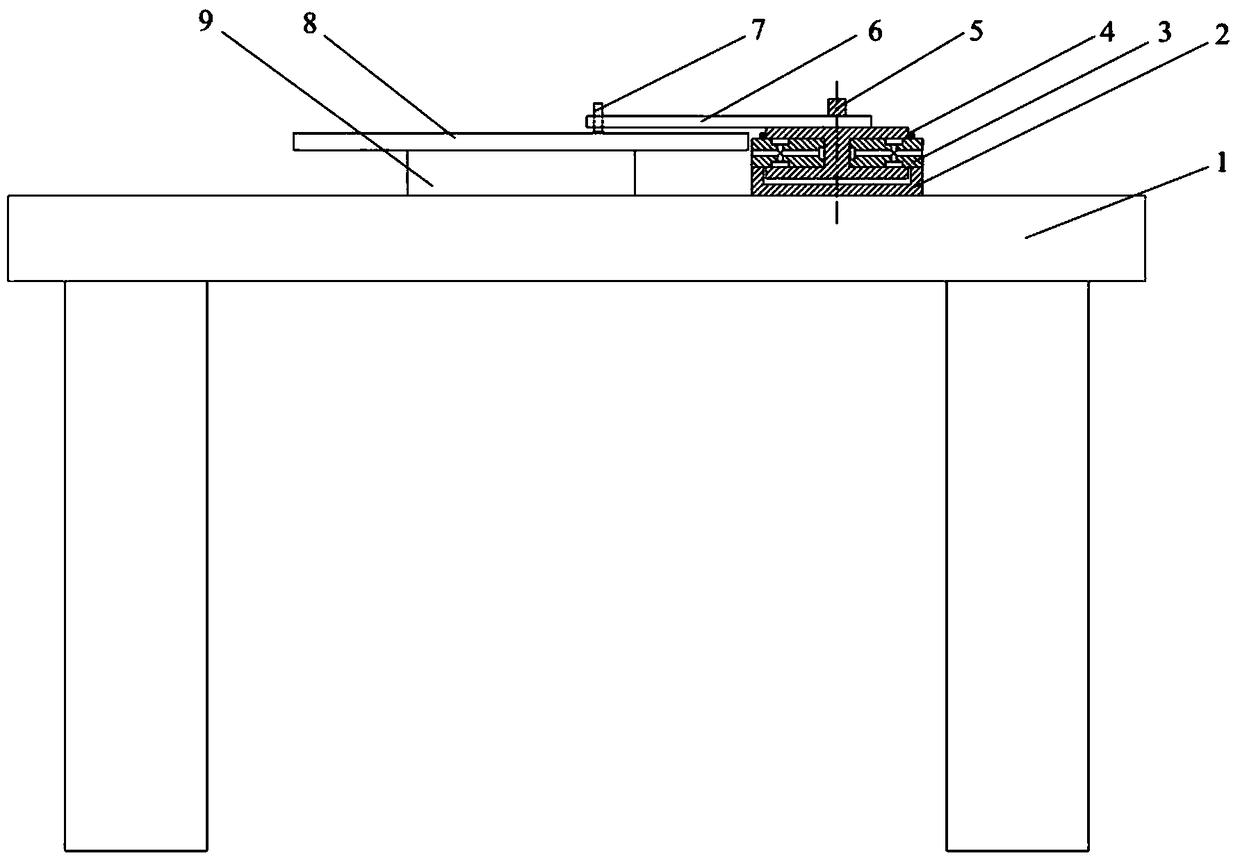

[0044] Such as Figure 1-4 As shown, a flatness detection device for a polishing disc of a large polishing machine includes a base 1, a gas static pressure bearing unit, a swing arm 6, a distance sensor 7, a polishing disc 8, a hydraulic turntable 9 and an industrial computer, and the gas The static pressure bearing unit includes a gas static pressure bearing seat 2, a gas static pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com