A hollow servo motor-driven electric spindle for ultrasonic cutting

A technology of servo motor and ultrasonic cutting, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems that affect the improvement of aviation industry and related fields, reduce the processing efficiency of parts, and burr on the edge and contour surface of parts, etc., to achieve effective It is conducive to the promotion and use of large-scale, improving the accuracy of rotation motion, and the effect of compact space layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the following will describe in detail the defrosting control system and method for the refrigerator of the present invention in conjunction with the accompanying drawings and specific implementation methods.

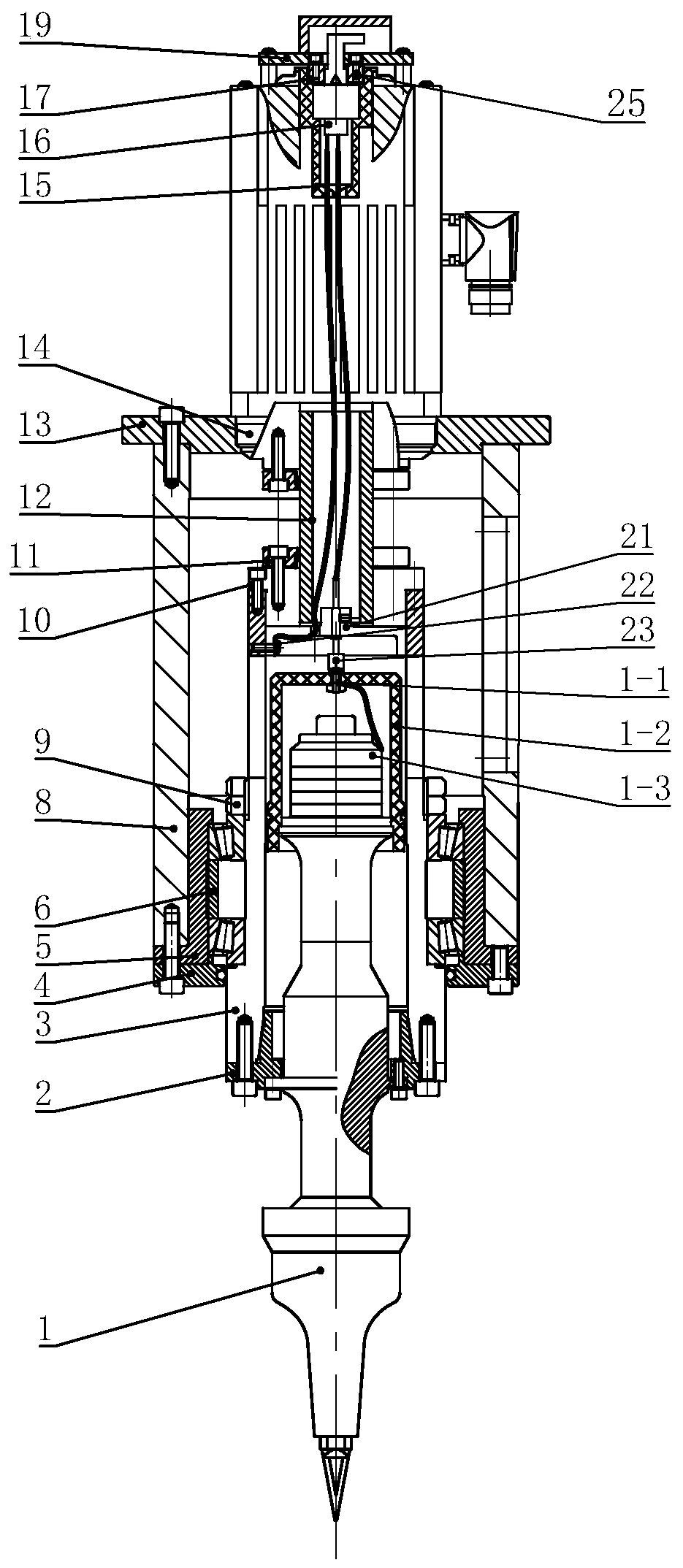

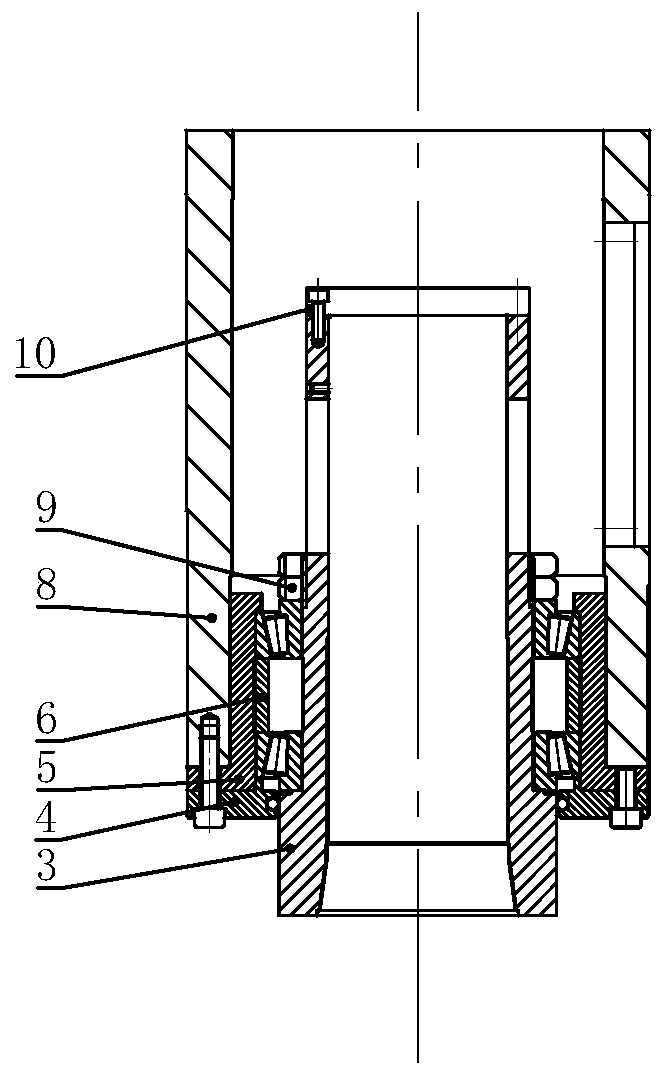

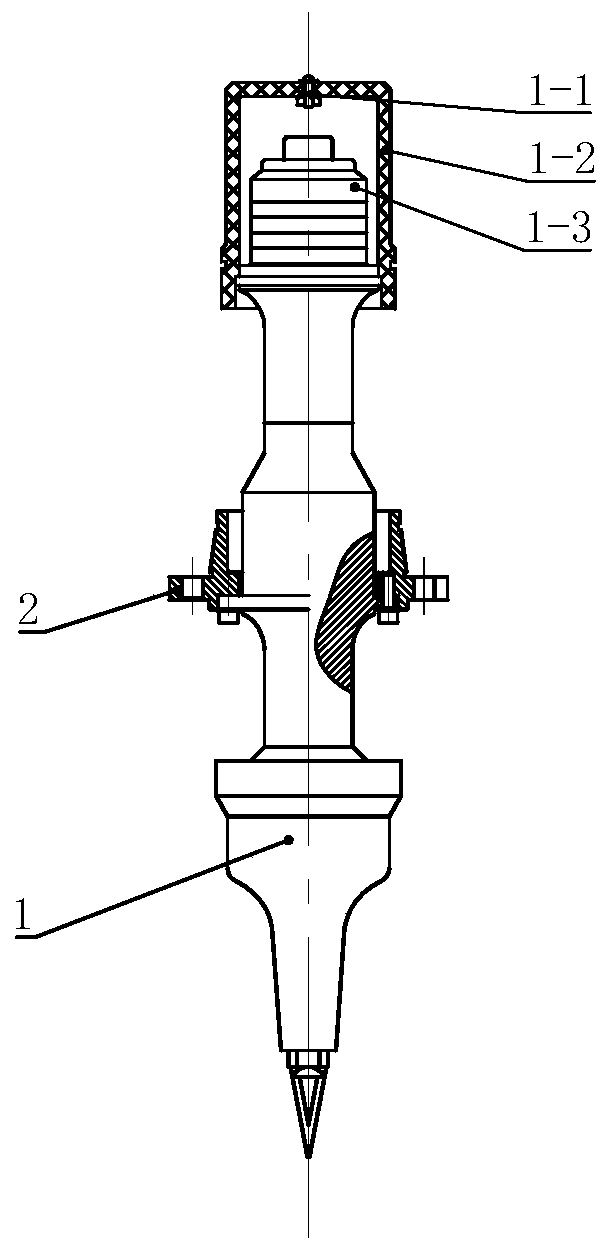

[0027] Such as figure 1 As shown in -4, the ultrasonic cutting electric spindle driven by the hollow servo motor of this embodiment includes the electric spindle body and the acoustic assembly 1, and the electric spindle body includes the hollow spindle 3, the bushing 5, the casing 8, the motor mounting plate 13 and Hollow servo motor 14. Wherein, the hollow main shaft 3 is installed in the shaft sleeve 5 through bearings, and the shaft sleeve 5 is coaxially installed on the lower end of the housing 8 , the upper end of the housing 8 is provided with a motor mounting plate 13 , and the hollow servo motor 14 is mounted on the motor mounting plate 13 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com