An extra-large tapered roller bearing with a pin-type cage

A tapered roller bearing and tapered roller technology, applied in the direction of bearing, bearing assembly, shaft and bearing, etc., to achieve the effect of improving the rotation precision, scientific and reasonable, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

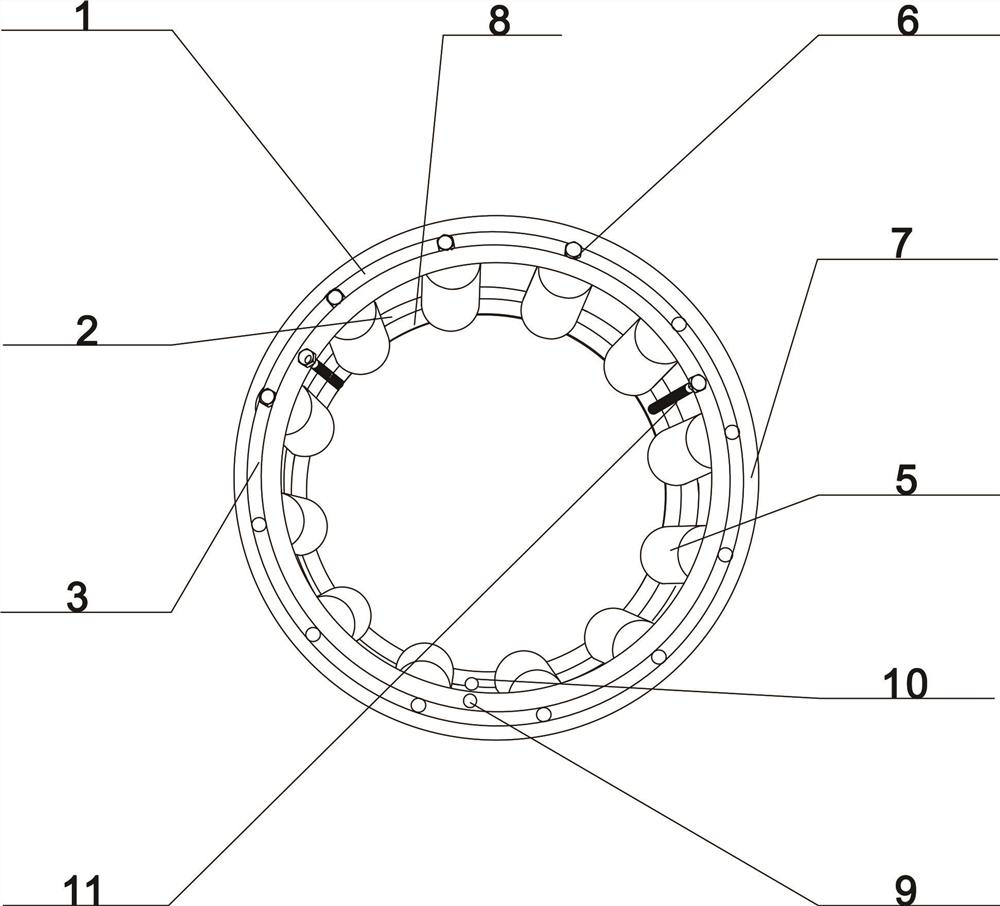

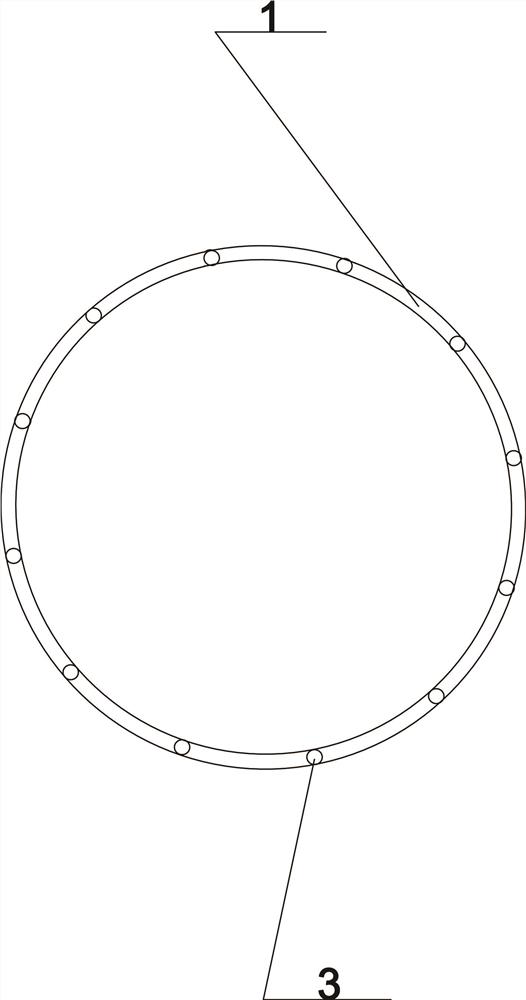

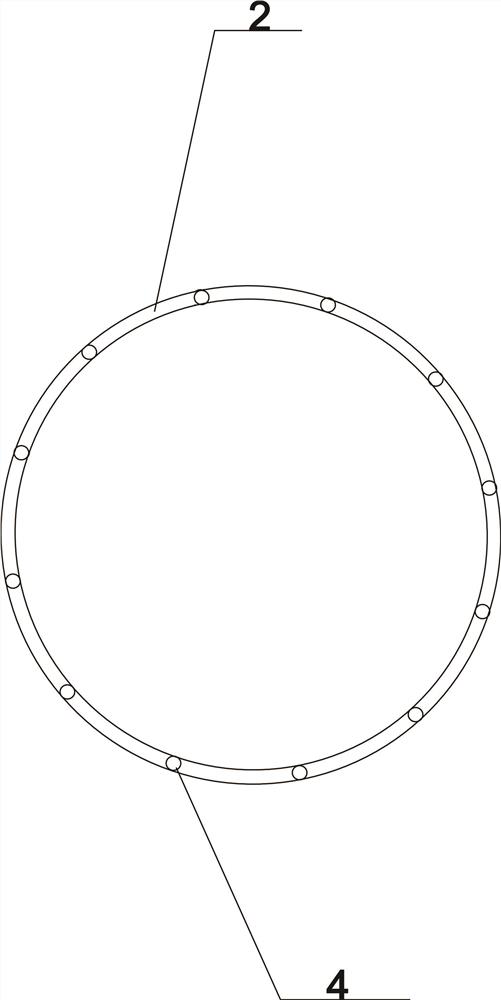

[0047] Embodiment 1. The countersunk head screw holes 9 are fixedly arranged on both sides of the edge of the upper pressure ring 7. The two countersunk head screw holes 9 are symmetrically arranged, and the countersunk head screw holes 9 pass through the body of the upper pressure ring 7. A through hole with internal thread; the wire hole 10 is fixedly arranged on one side of the lower pressing ring 8; the pressing screw 11 is arranged on the edges of both sides between the tapered rollers 5, and the pressing screw 11 passes through The countersunk head screw holes 9 of the upper pressure ring 7 are tightened with the screw holes 10 of the lower pressure ring 8, and a number of pressure screws 11 are arranged at equal distances in the circumferential direction between the upper pressure ring 7 and the lower pressure ring 8. The upper holding ring 1 , the lower holding ring 2 , the tapered roller 5 , the upper pressing ring 7 and the lower pressing ring 8 are connected as a who...

Embodiment 2

[0048] Embodiment 2. On the basis of the technical solution of the present invention, three to eight groups of pressing screws 11 are arranged at equal distances in the circumferential direction between the upper pressing ring 7 and the lower pressing ring 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com