Motor and method for improving running reliability of motor

A reliability and bearing technology, applied in the field of electric motors, can solve problems such as aggravating bearing damage, loosening of bearing inner ring and shaft 05, severe friction of bearing temperature, etc., to achieve the effect of extending service life, improving tolerance requirements, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

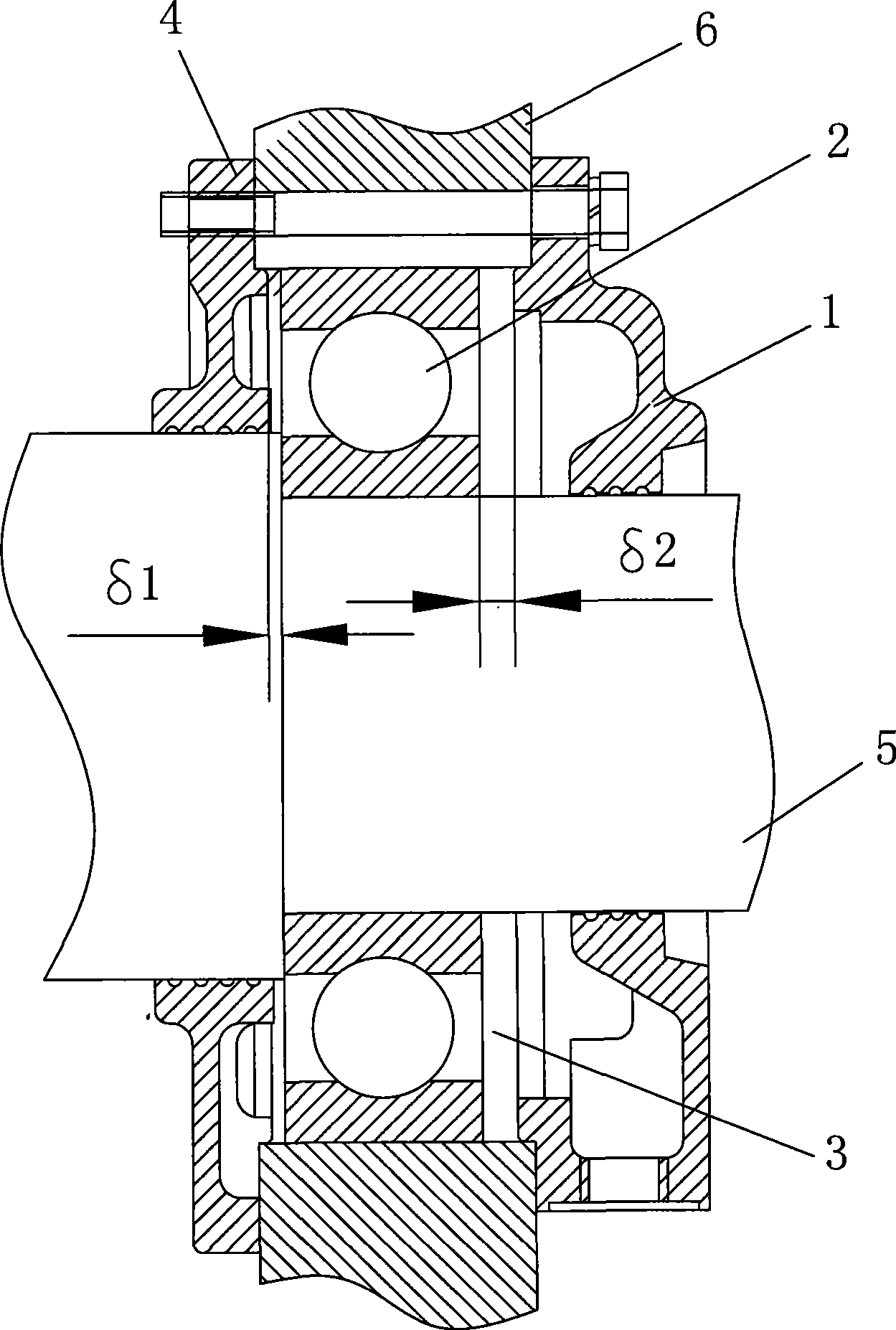

[0029] See attached figure 2 , the present invention includes:

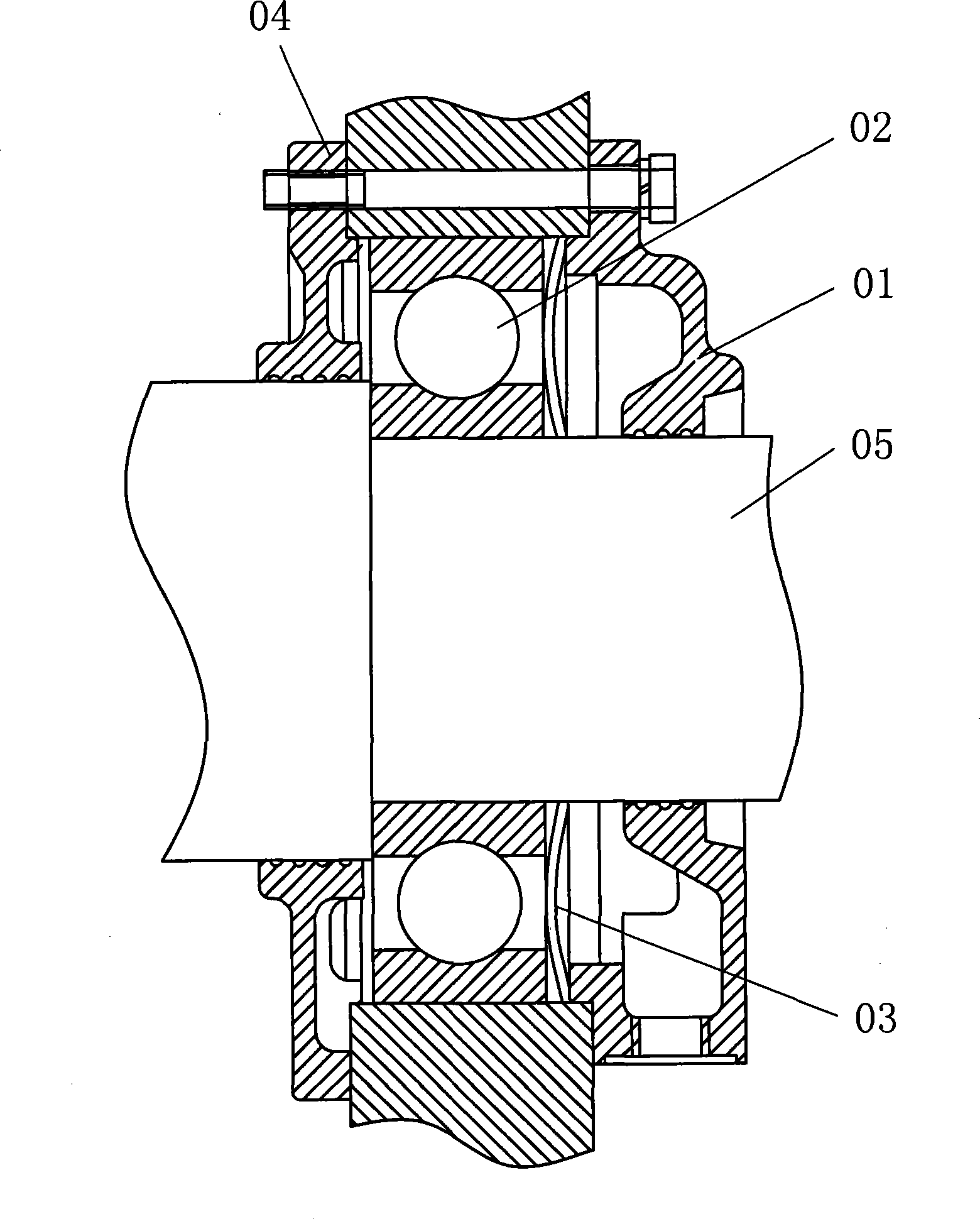

[0030] It includes bearing outer cover 1, bearing 2, bearing inner cover 4, shaft 5, bearing outer cover 1, bearing 2, bearing inner cover 4 are installed on the shaft 5 in sequence, and bearing 2 is located between bearing outer cover 1 and bearing inner cover 4 There is a movable gap 3 between the end face of the outer ring of the bearing 2 and the inner spigot of the bearing outer cover 1.

[0031] The bearing 2 is covered with a bearing sleeve 6 .

[0032] In the present invention, the axial distance between the end face of the bearing outer cover 1 and the end face of the outer ring of the bearing 2 is adjusted, and the conventional wave spring sheet or bearing spring is changed into a large gap, that is, the wave spring sheet or bearing spring is removed, so that the bearing outer cover 1 stops. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com