Throttling cooling structure and system for mold

A mold and cooling device technology, which is applied in the field of throttling cooling structure and system for molds, can solve the problems that the cooling flow channel cannot cover the product, affect the product quality, and uneven cooling, and achieve the convenience of inserting the auxiliary cooling place and structure of the mold Simple and reliable, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

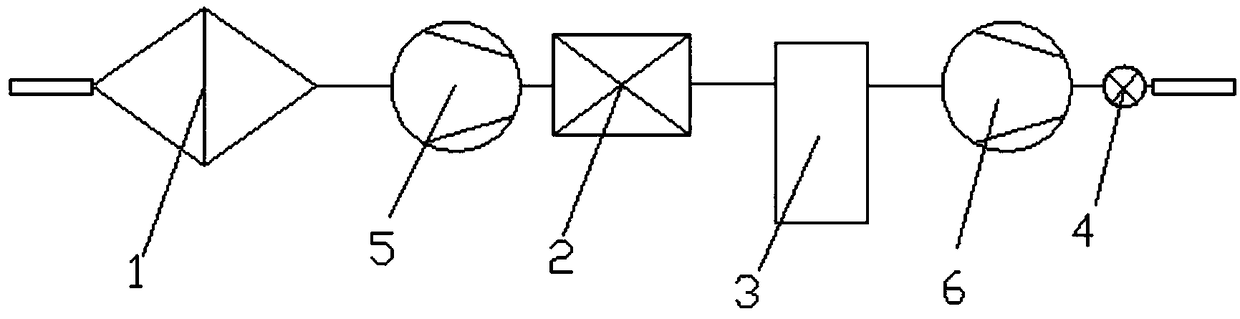

[0021] This embodiment shows a throttling cooling system for molds, which consists of several throttling cooling devices for molds connected in parallel, and the throttling cooling devices for molds are all connected to the pressure regulating device.

[0022] see figure 1 The mold throttling cooling device includes an air filter 1, a cooling dehumidification device 2 connected to the air filter 1, an adsorption drying device 3 connected to the cooling dehumidification device 2, and a throttling device 4 connected to the adsorption drying device 3;

[0023] The throttling device 4 is composed of microporous tubes; after the air passes through the air filter 1, the cooling dehumidification device 2, and the adsorption drying device 3 for filtration, dehumidification, and drying, since the throttling device 4 is composed of microporous tubes, the passage area is reduced , to boost the pressure, after the throttling device 4 is inserted into the place where the mold needs auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com