Omni-directional aircraft ground working platform using McNam wheels

A working platform and ground technology, applied in aircraft maintenance, aircraft cleaning, etc., can solve problems such as low work efficiency, a lot of time, and time waste, and achieve the effects of saving time, avoiding waste, and improving work efficiency

Inactive Publication Date: 2019-01-22

ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At this stage, when performing aircraft ground maintenance, the working platform mostly uses ordinary cars. When turning, a large amount of space is required for steering actions. It usually takes a lot of time to adjust the position, resulting in waste of time and low work efficiency.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

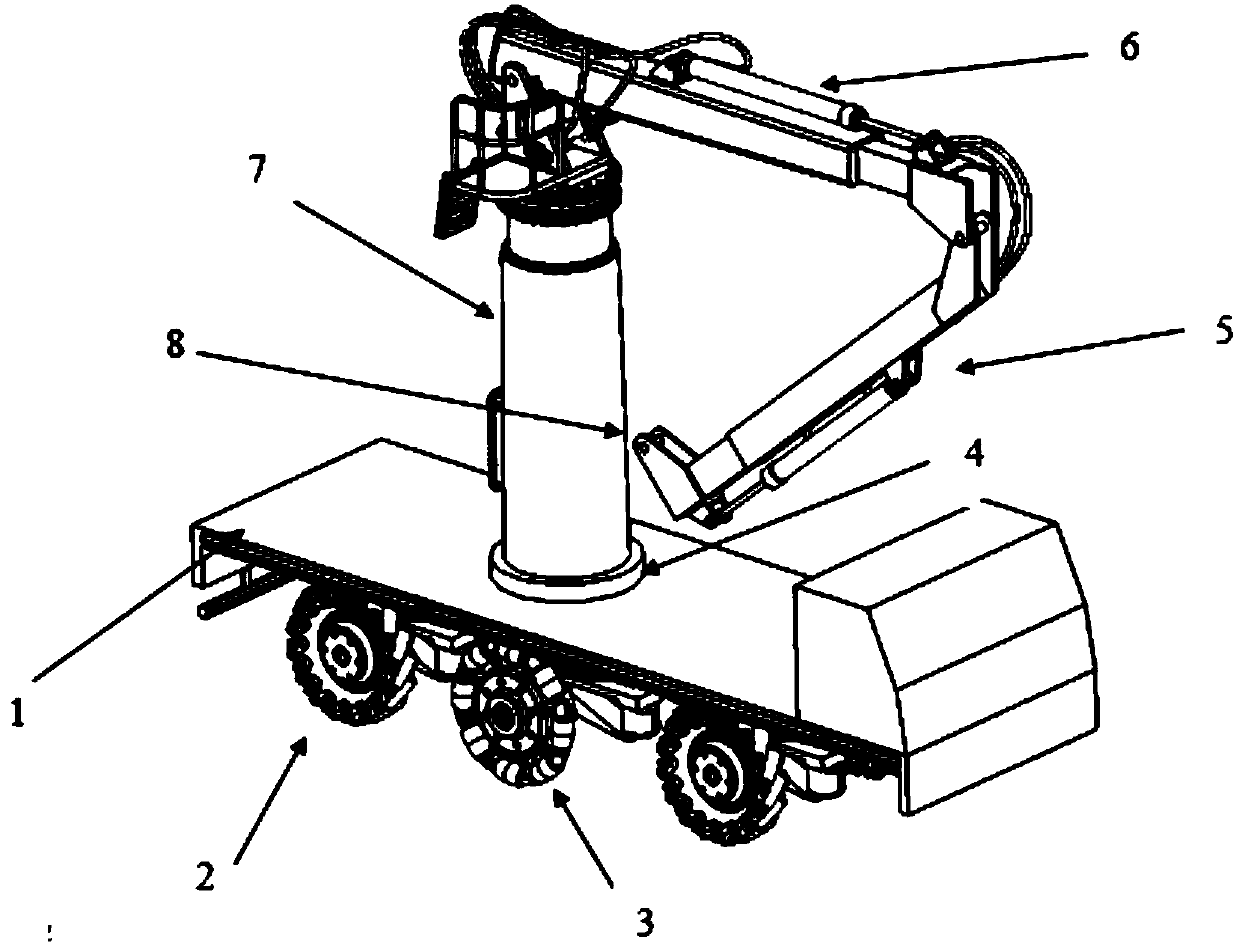

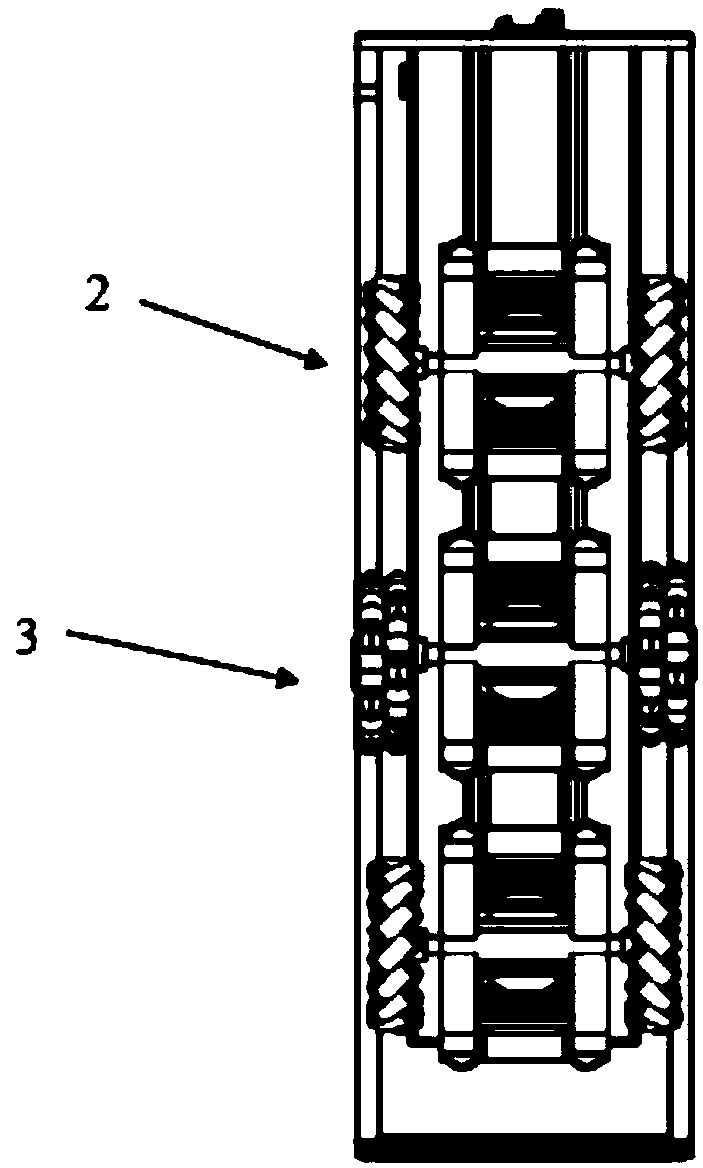

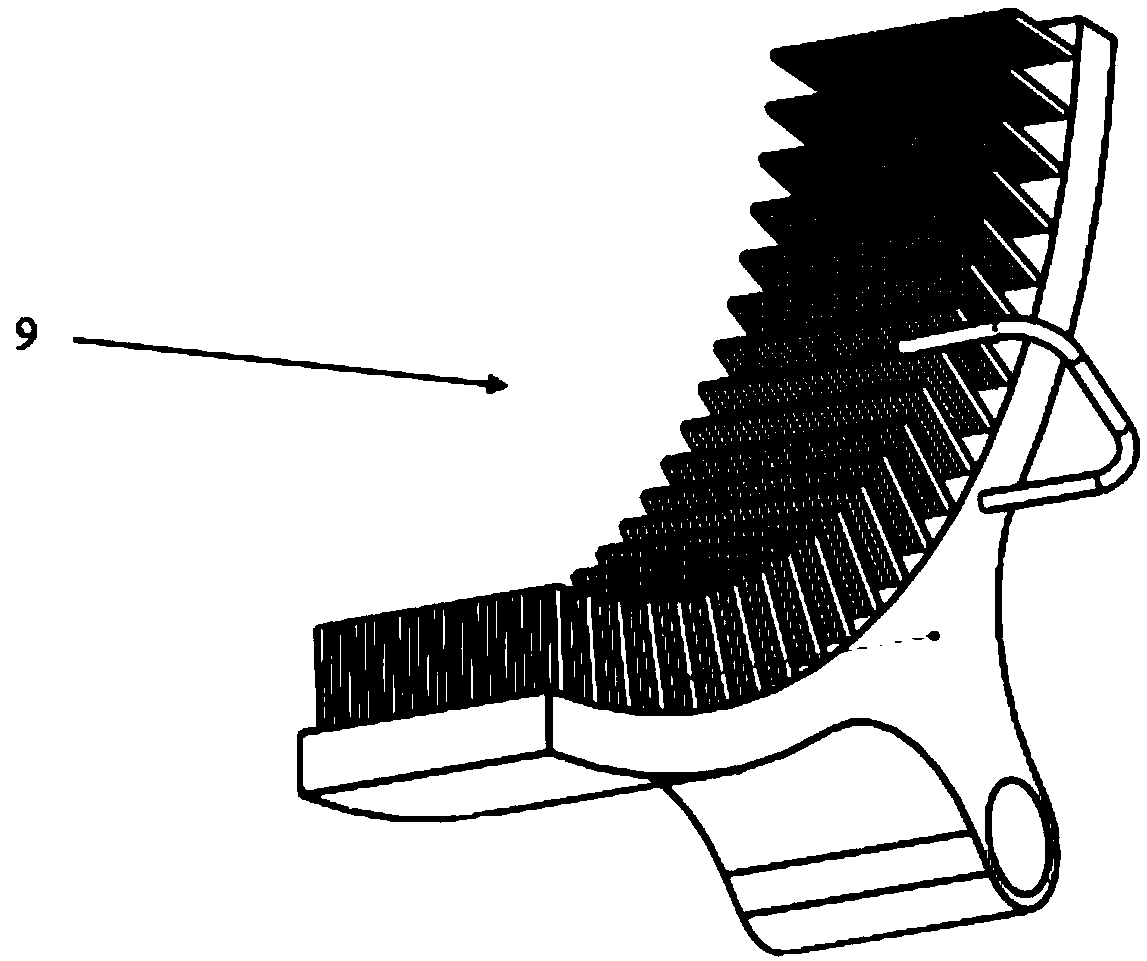

The invention discloses an omni-directional aircraft ground working platform using McNum wheels, comprising an omni-directional moving body, a McNum wheel, an omni-directional wheel, a 360-degree rotating base, a first lifting arm, a second lifting arm, a hydraulic lifting column and a working platform interface. Two pairs of McNam wheels are arranged under that omni-directional moving body, and apair of omni-directional wheels are arranged between the two pairs of McNam wheels; the 360-degree rotary base is fixed above that omni-directional moving body, the hydraulic lifting column is vertically installed on the 360-degree rotary base, the top end is connected with the second lifting arm by a rotating mechanism, the second lifting arm and the first lifting arm are connected with each other by a hydraulic lifting mechanism, and the end of the first lifting arm is provided with a working platform interface. The omni-directional aircraft ground working platform using McNam wheel is simple in structure and convenient in use, and can greatly improve the working flexibility, enlarge the working area, and ensure higher working efficiency.

Description

technical field The invention relates to an aircraft ground working platform, in particular to an omnidirectional aircraft ground working platform using a mecanum wheel. Background technique At this stage, when performing aircraft ground maintenance, the working platforms are mostly ordinary cars. When turning, a large amount of space is required for steering actions. It usually takes a lot of time to adjust the position, resulting in waste of time and low work efficiency. Therefore, there is an urgent need to provide an omnidirectional aircraft ground work platform with a simple structure and easy to use using mecanum wheels. Contents of the invention The purpose of the present invention is to provide an omnidirectional aircraft ground working platform using mecanum wheels, which has a simple structure and is easy to use, can greatly improve working flexibility and expand the working area area, to ensure high work efficiency. In order to achieve the above object, the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B64F5/40B64F5/30

CPCB64F5/30B64F5/40

Inventor 汪奇韩岭峰孙帅沈怡

Owner ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com