Anti-reflection system and method of high-pressure air pulse water wave periodically hammering coal body

A high-pressure air and high-pressure gas technology, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of small extraction influence range, short extraction time period, and high extraction cost, so as to improve safety and efficiency. The effect of production efficiency, reduction of economic cost input, and simplified operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

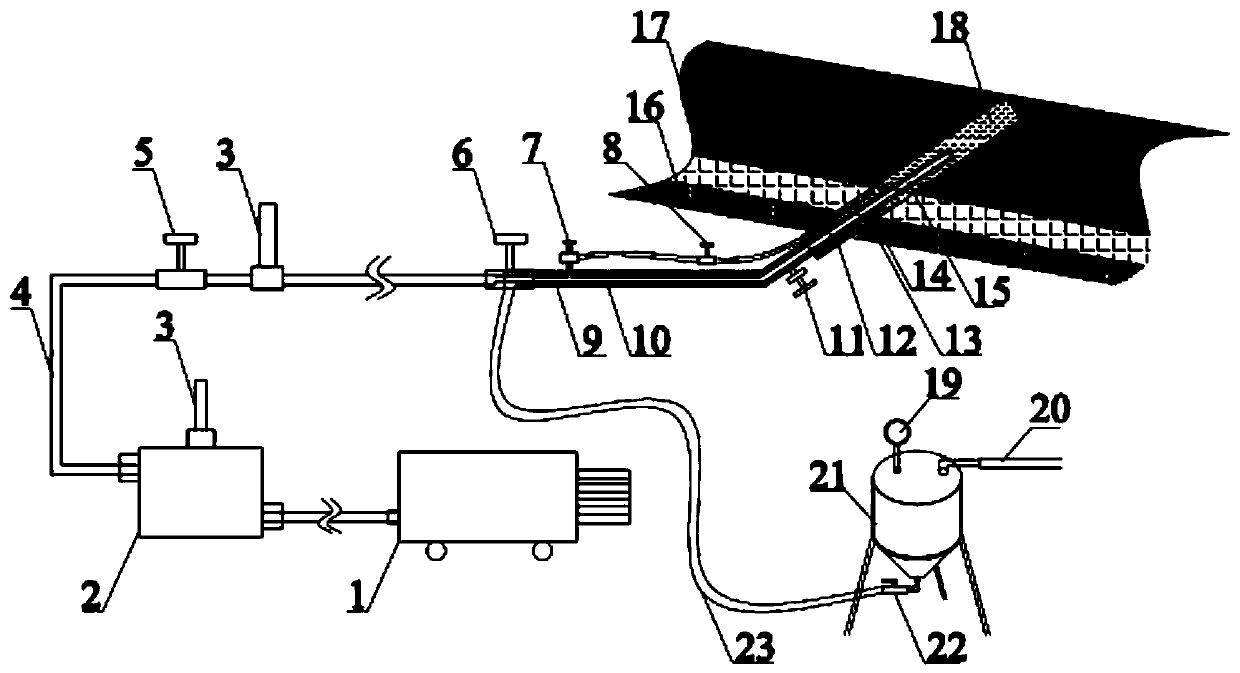

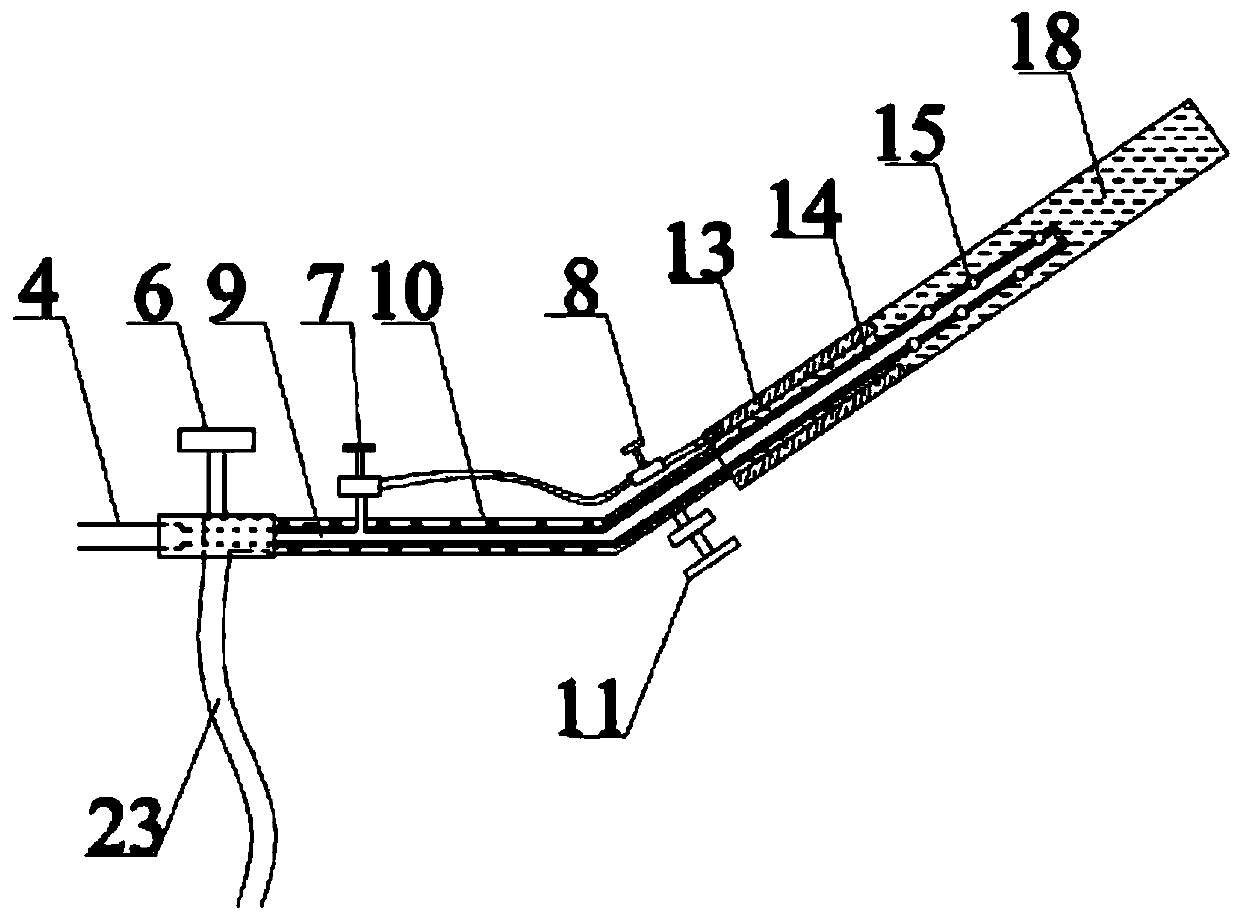

[0032]This embodiment proposes a high-pressure air pulse water wave periodic hammering coal body anti-reflection system, including a water filling device, an air charging device, and fracturing equipment. The fracturing equipment includes a high-pressure gas release pipe 14, a sealing capsule 13, and a high-pressure double-layer conveying pipe , the high-pressure double-layer conveying pipe comprises a high-pressure double-layer gas delivery inner pipe 9 of an inner layer and a high-pressure double-layer water delivery outer pipe 10 of an outer layer, and the high-pressure double-layer gas delivery inner pipe 9 ends are connected with a high-pressure gas release pipe 14, and A number of one-way gas release holes 15 are distributed on the gas release pipe 14, and the sealing capsule 13 is arranged on the outer wall of the high-pressure double-layer delivery pipe close to the position of the high-pressure gas release pipe 14; the water filling device communicates with the high-pre...

Embodiment 2

[0040] This embodiment proposes a method of periodically hammering the coal body with high-pressure air pulse water waves for anti-reflection, using the high-pressure air pulse water waves periodically hammering the coal body anti-reflection system in Example 1, and high-pressure air pulse water waves periodically hammering the coal body for anti-reflection The method includes the following steps:

[0041] Step 1. Construct the layer-penetrating fracturing hole 12 in the floor rock layer 16 of the underground rock roadway to enter the target coal seam 17, and control holes can be arranged on the side. Connect to the high-pressure double-layer water delivery outer pipe 10 and the high-pressure double-layer gas delivery inner pipe 9, then pass through the longitudinal center of the sealing capsule 13 as a whole, and send the high-pressure gas release pipe 14 and the sealing capsule 13 into the fracturing hole together 12, by filling the sealing capsule 13 with high-pressure gas,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com