Micro-dosage safety syringe

A safety syringe and micro-dosing technology, applied in the directions of syringes, hypodermic injection devices, infusion sets, etc., can solve the problems that the syringe can not be made into a very small diameter, cannot achieve micro-control, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

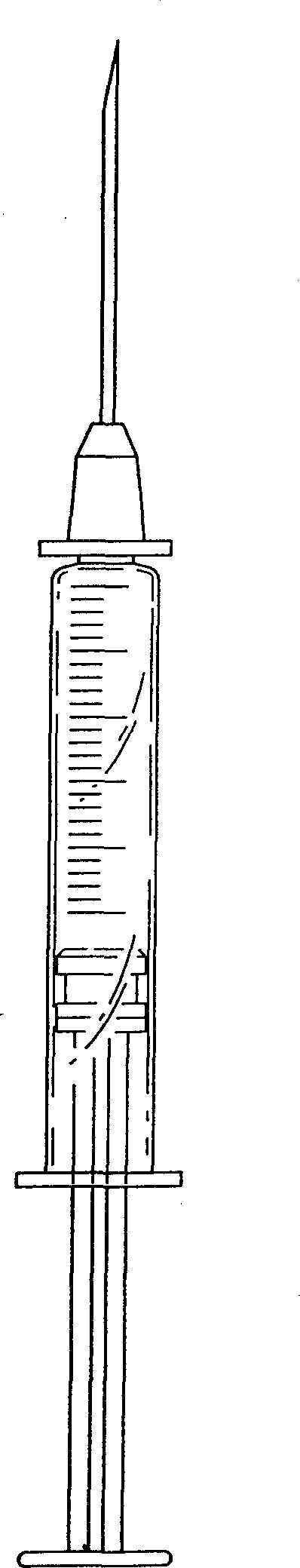

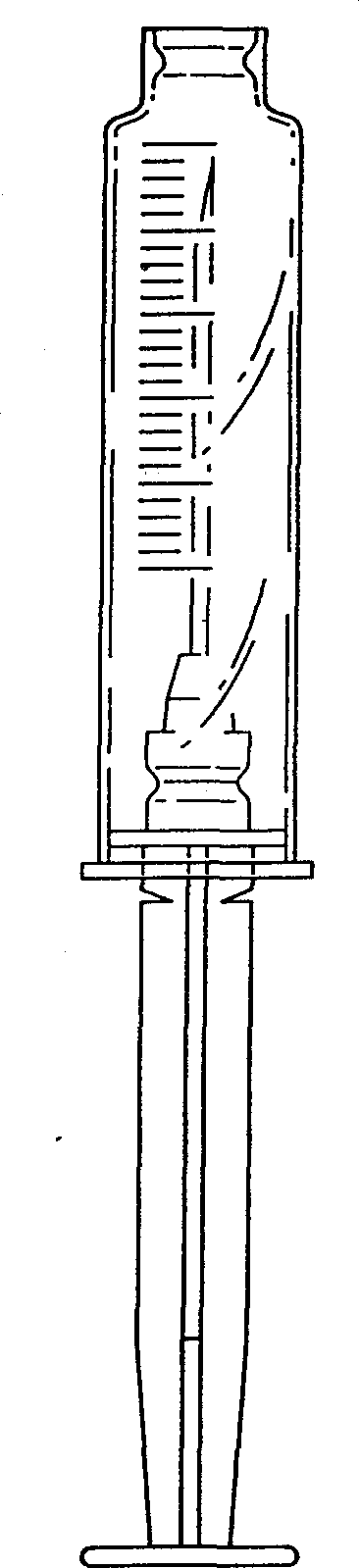

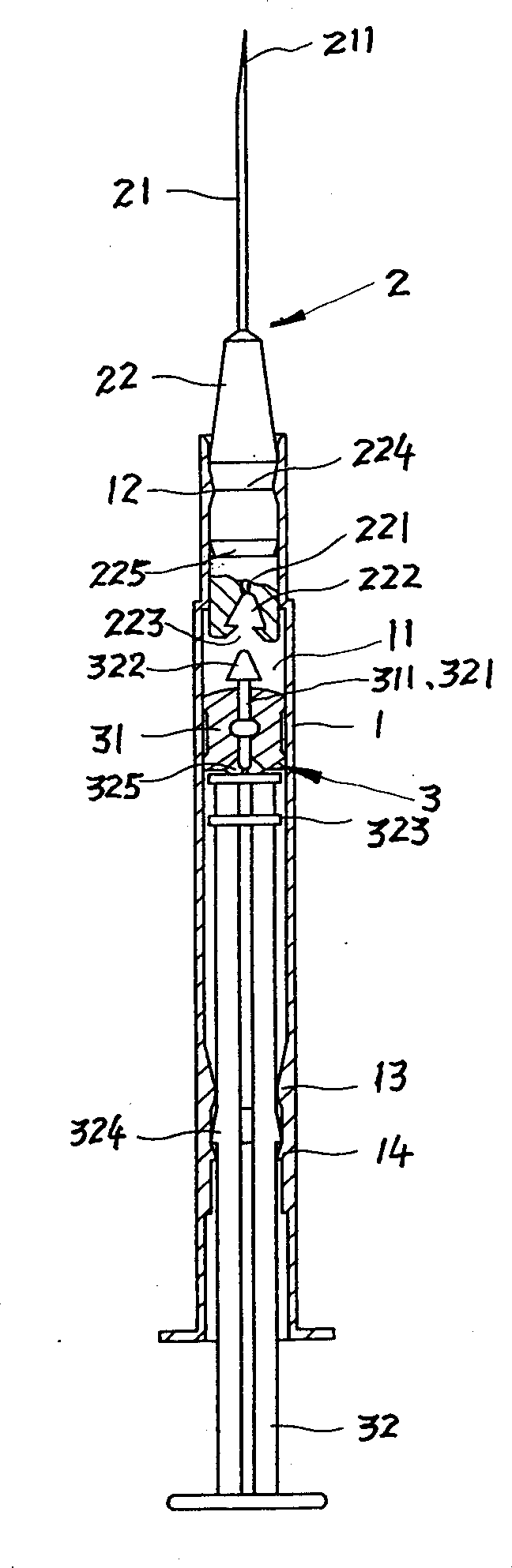

[0015] like image 3 As shown, the present invention is composed of a syringe 1, a needle group 2 and a piston group 3. The syringe 1 is a cylinder body forming a hollow cavity 11. A stopper 12 is provided, and upper and lower stoppers 13, 14 are provided at the rear end of the inner circumference of the syringe 1, and the lower stopper 14 is formed at an acute angle; the front and rear ends of the needle group 2 are hollow needle bodies 21 and The needle handle 22, the front end of the needle body 21 forms a needle point 211, the needle handle 22 is elastic, and a central through hole 221 is arranged on it, and the center line is formed at the bottom of the central through hole 221. Shaped recess 222, below the tapered recess 222 is provided with a bell mouth 223 connected with it, and the outer periphery of the needle handle 22 is provided with the front end mouth 12, the rear end upper and lower seam mouths 13, 14 of the syringe 1 respectively. Fitted upper and lower groov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap