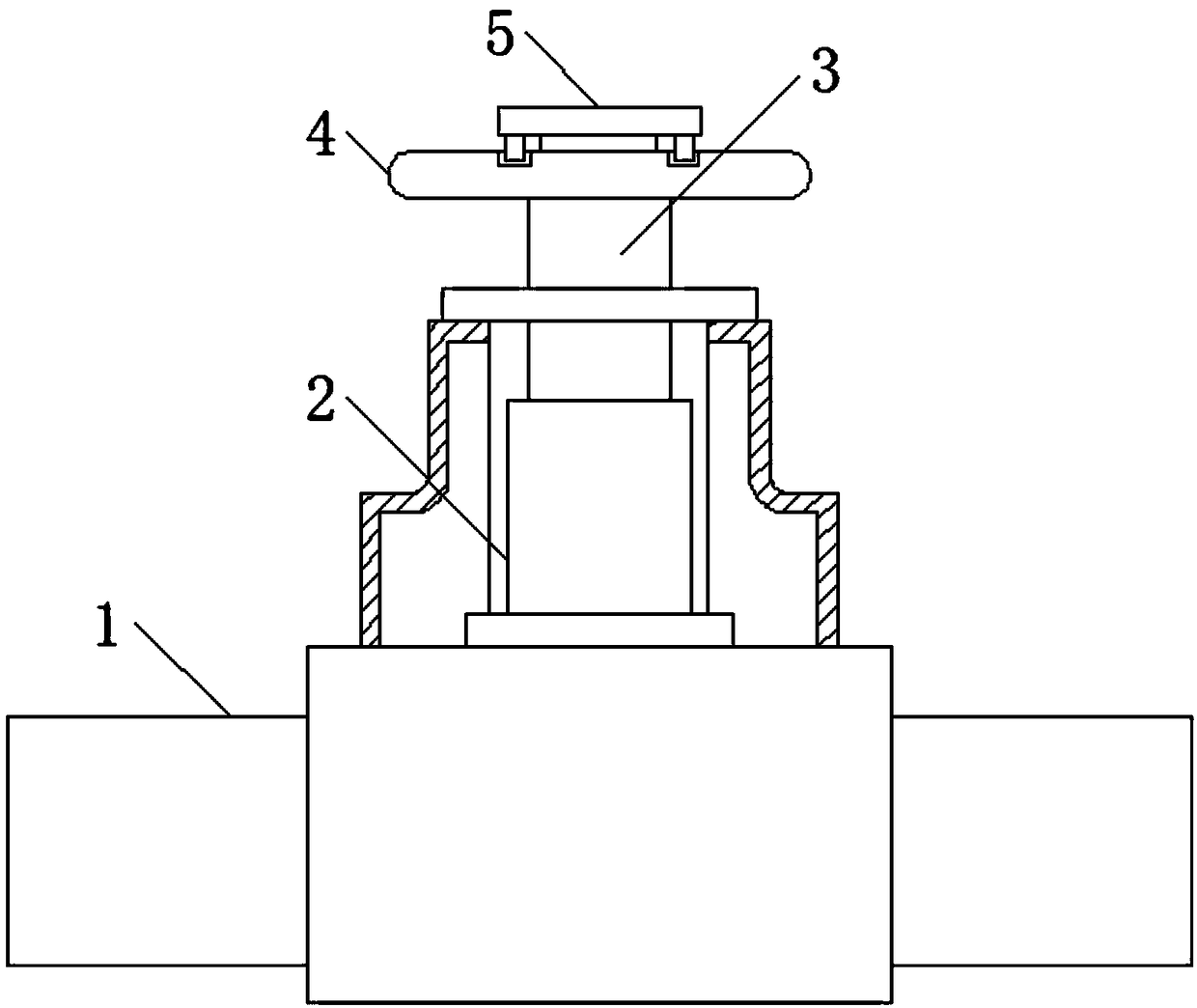

Heavy-duty one-character locking ball valve

A locking and heavy-duty technology, applied to valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of inconvenient disassembly, difficult replacement and maintenance, etc., and achieve the effect of easy disassembly and maintenance, and convenient fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

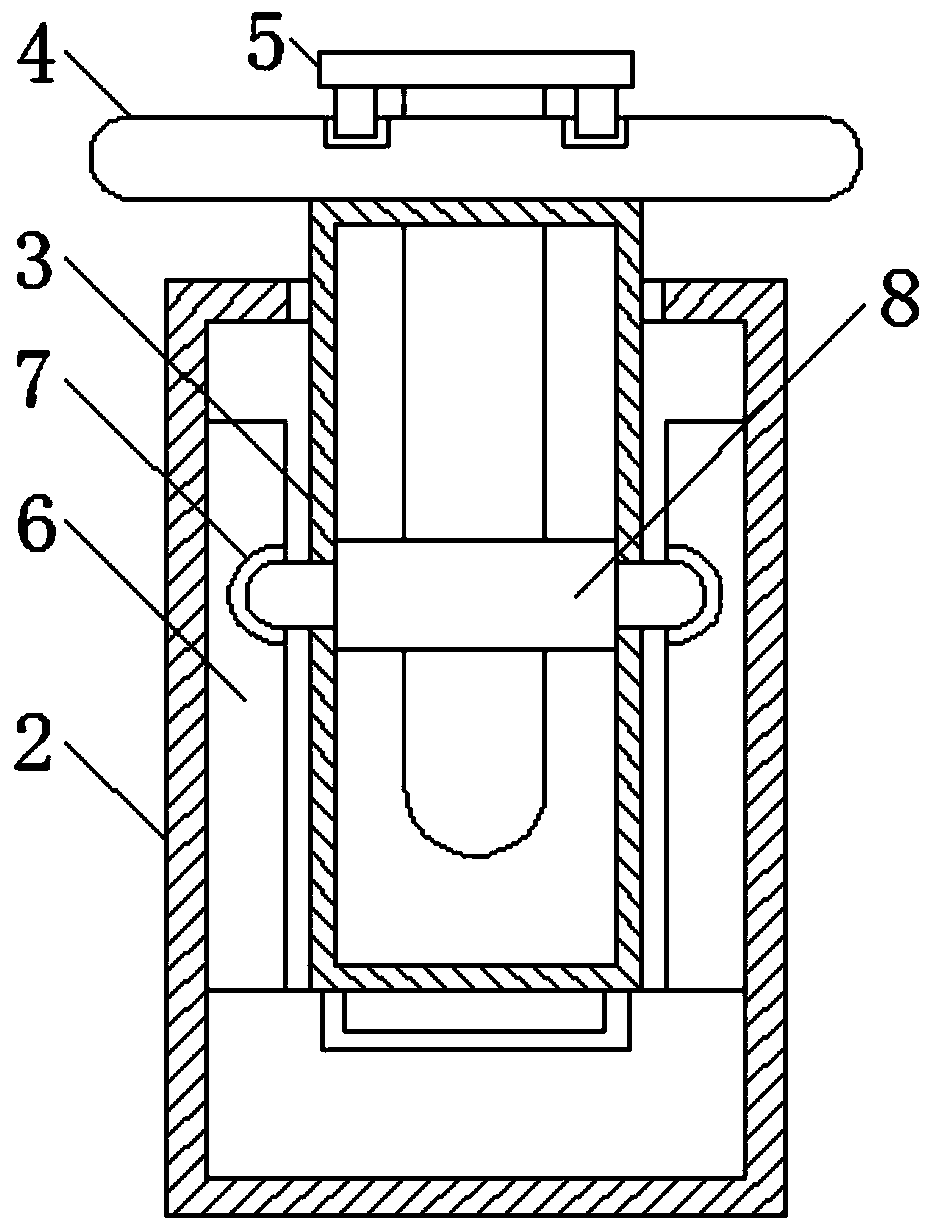

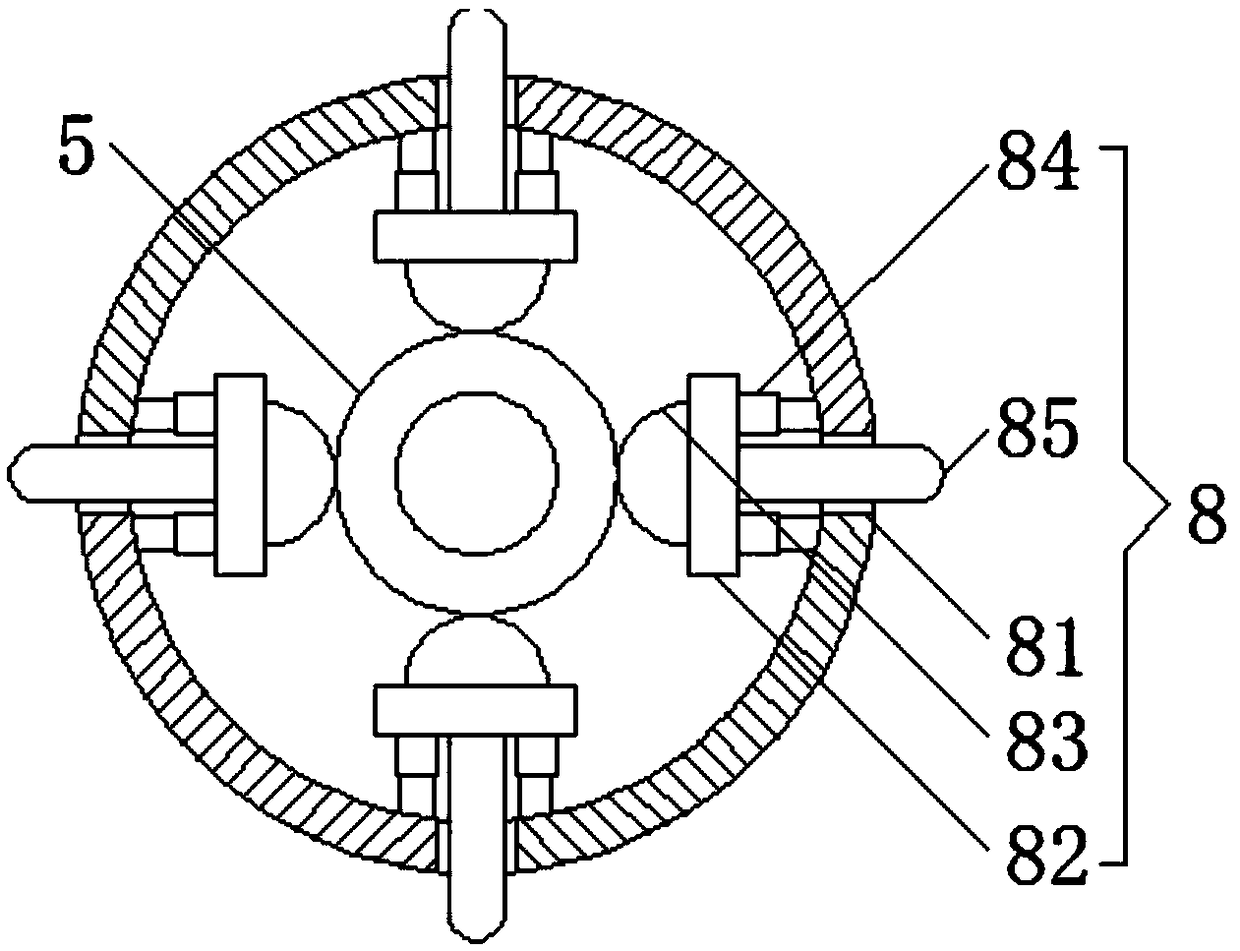

[0022] Embodiment: When installing and using the ball valve, first install the valve stem 2 on the valve body 2, then insert the rotating screw 3 into the valve stem 2, and finally insert the movable ejector rod 5 into the rotating screw 3, and pass The cooperation between the movable ejector rod 5 and the clamping device 8 clamps the rotary screw rod 3 and the valve stem 2 together, so that the movable ejector rod 5 slides downward in the rotary screw rod 3, and the bottom and the outer wall of the movable ejector rod 5 will be four The group of bumps 83 is ejected outwards, and the bumps 83 move in the fastening collar 81 through the movable plate 82 and the spring bar 84, and the movable plate 82 drives the stop rod 85 to be plugged in the limit hole 7, which can be conveniently Connect the rotary screw 3 with the valve stem 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com