Pipeline robot and cleaning method thereof

A pipeline robot and casing technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of reducing overall efficiency, cleaning in place, cleaning dead corners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

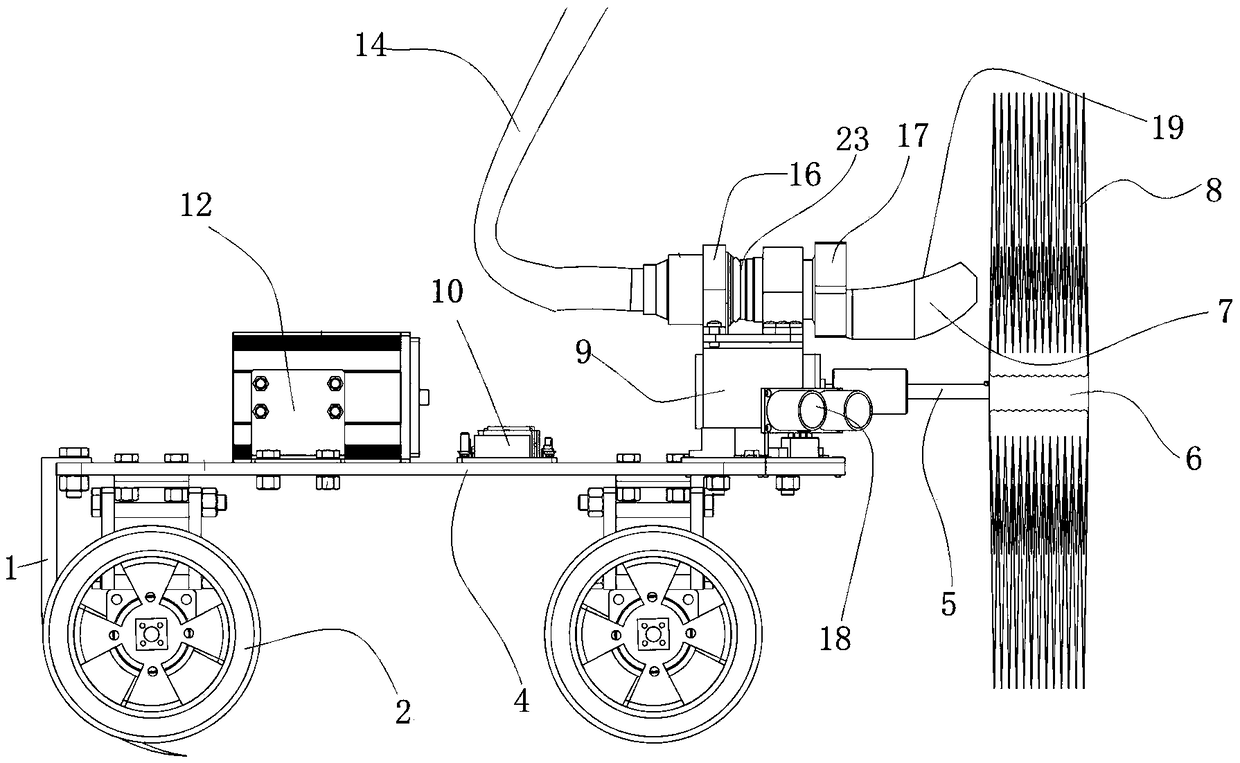

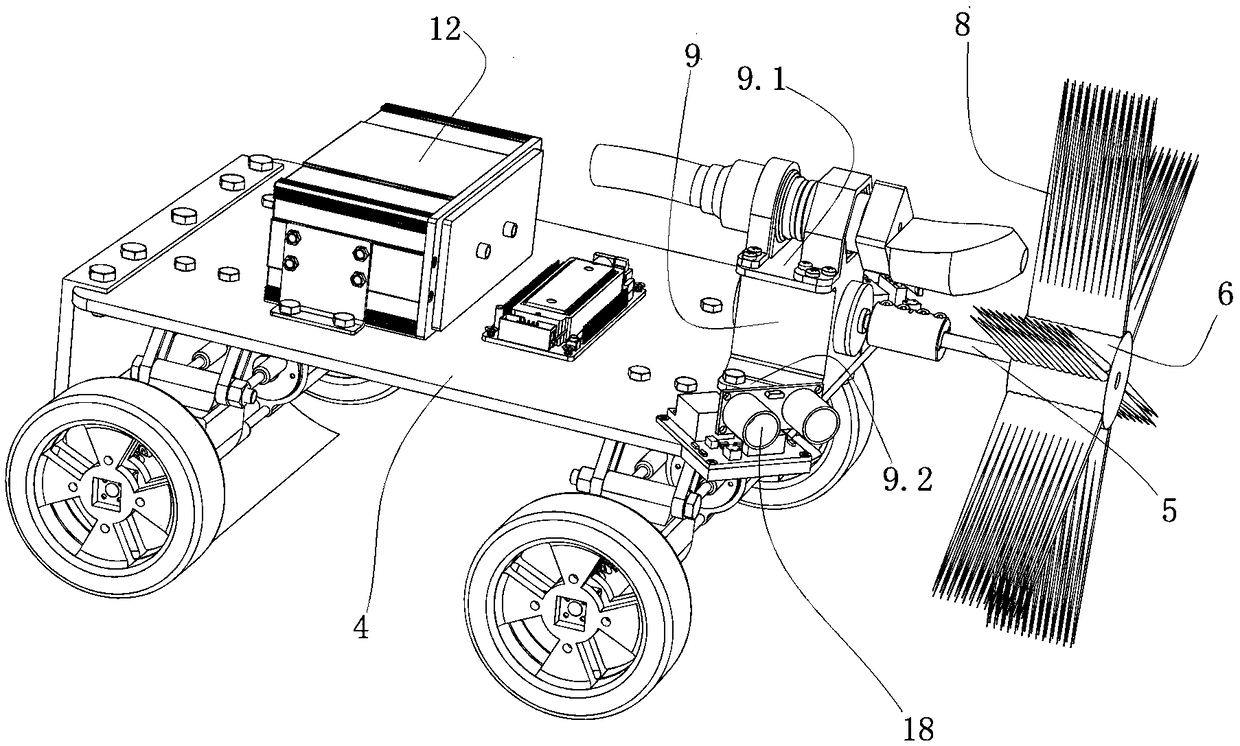

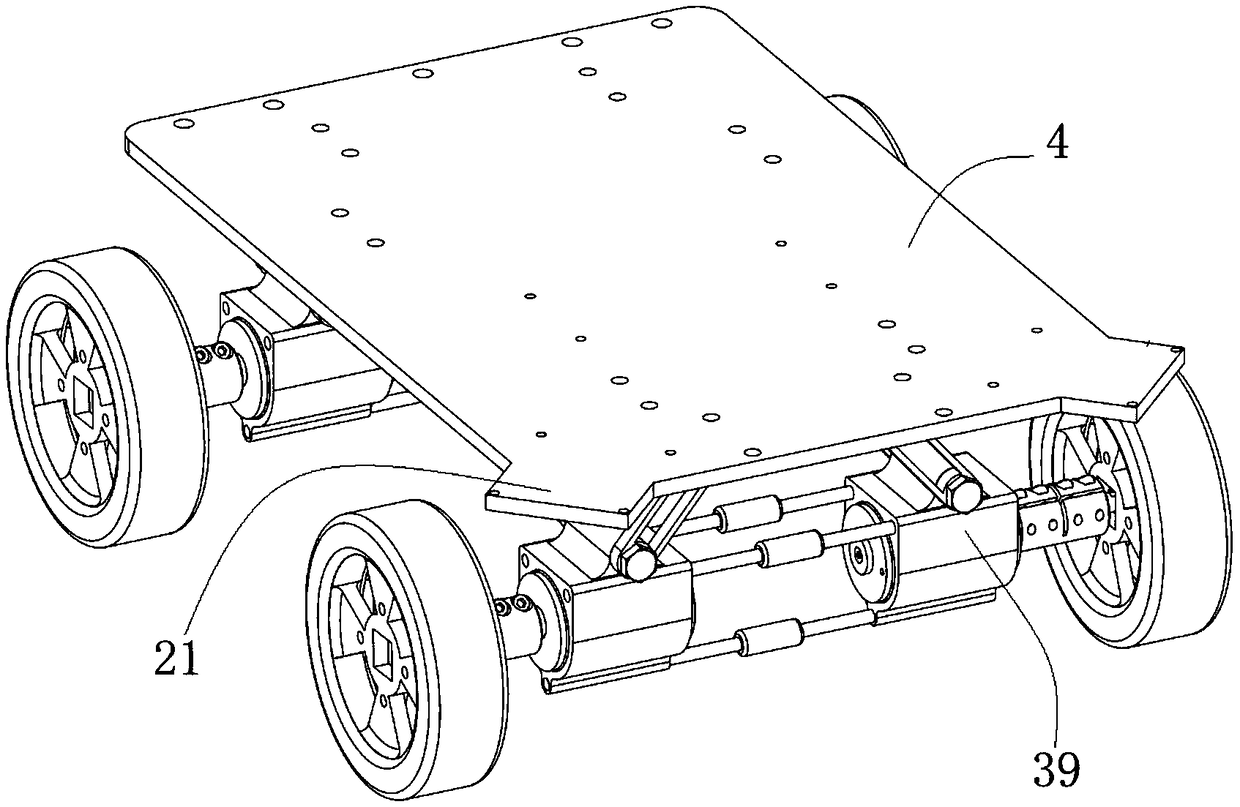

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] as attached Figures 1 to 6 A pipeline robot shown includes a horizontal vehicle frame 4, and the lower side of the horizontal vehicle frame 4 is provided with two walking units 2 arranged front and back; The lower locking plate 9.2 is integrally arranged, and the lower locking plate 9.2 is arranged on the upper side of the front part of the horizontal vehicle frame 4 through several bolts; Front extension; the end of the said water rejection output rotating shaft 5 is fixedly provided with a cylindrical brush seat 6; the circumferential wall of the brush seat 6 is evenly distributed with several groups of water rejection brushes 8 in a circular array, each group The brushes 8 extend outward in a divergent shape, and each group of brushes 8 rotates synchronously with the brush holder 6; a water spray unit is also included, and the water spray end of the water s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com