Vertical-opened horizontal-concealed glass curtain wall

A technology of glass curtain wall and horizontal concealment, which is applied in the direction of walls, buildings, and building components. It can solve the problems of difficult quality control, diverse processes, and falling off of decorative covers, so as to achieve good connection structure stability, improve wind resistance, and The effect of ensuring the stability of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

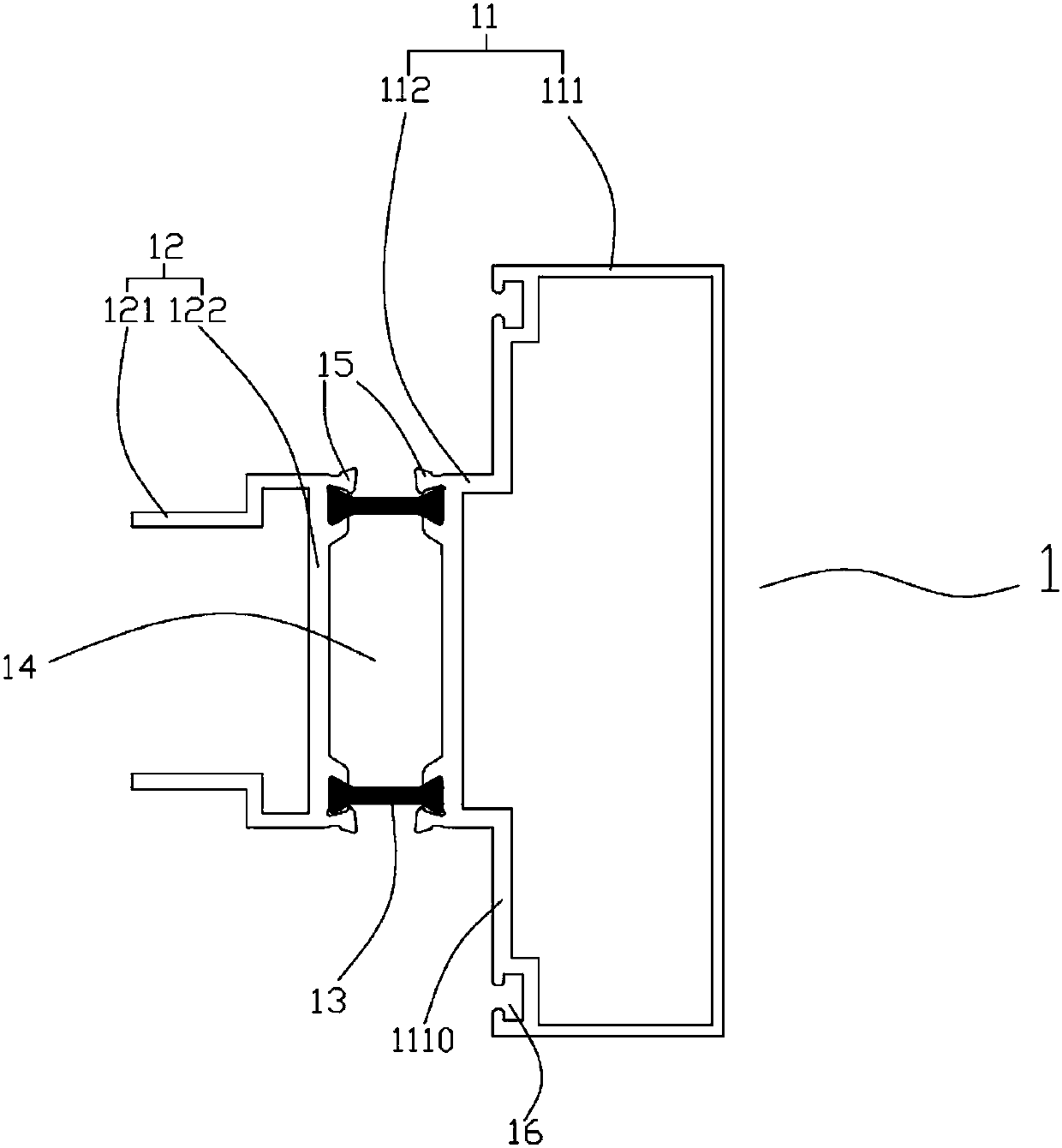

[0026] Such as figure 1 , Figure 4 and Figure 5 , the embodiment of the present invention provides a curtain wall pressure block 1, including a support 12 and a pressure plate 11 for pressing against the outer sides of two adjacent curtain wall panels 6, and the support 12 includes a support for respectively tightening through the first screw thread. Firmware 71 and two connecting plates 121 that are fixedly connected to the two sides of the corresponding curtain wall supporting frame member, and the two connecting plates 121 are connected to the pressing plate 11 and are provided with the first threaded fastener 71 Adaptive fastener piercing holes. It is easy to know that the above-mentioned curtain wall supporting frame members are columns 4 or beams 5, and the corresponding curtain wall supporting frame members are different according to the arrangement direction (vertical or horizontal) of the two curtain wall panels 6 connected by the pressing block 1, This is easily...

Embodiment 2

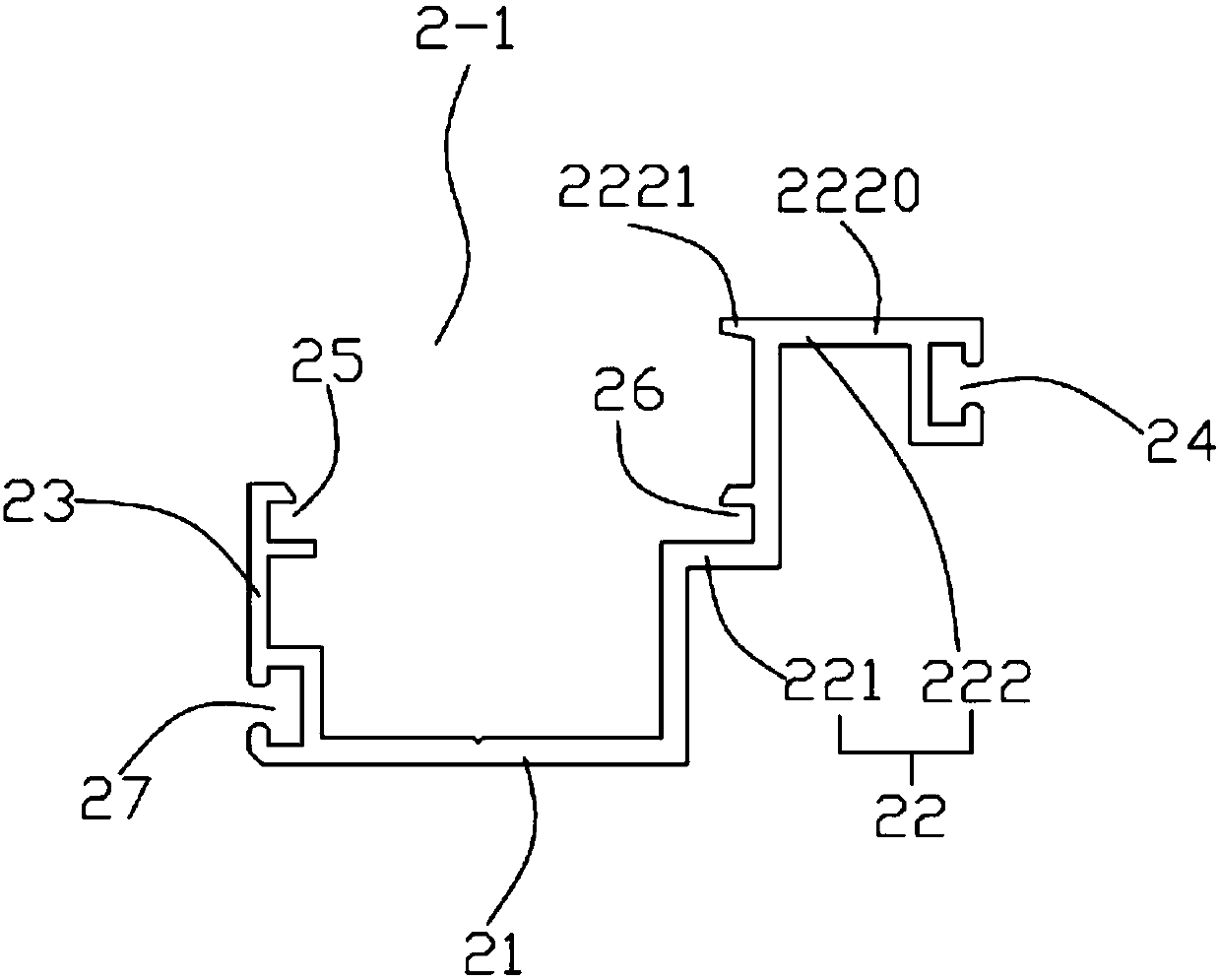

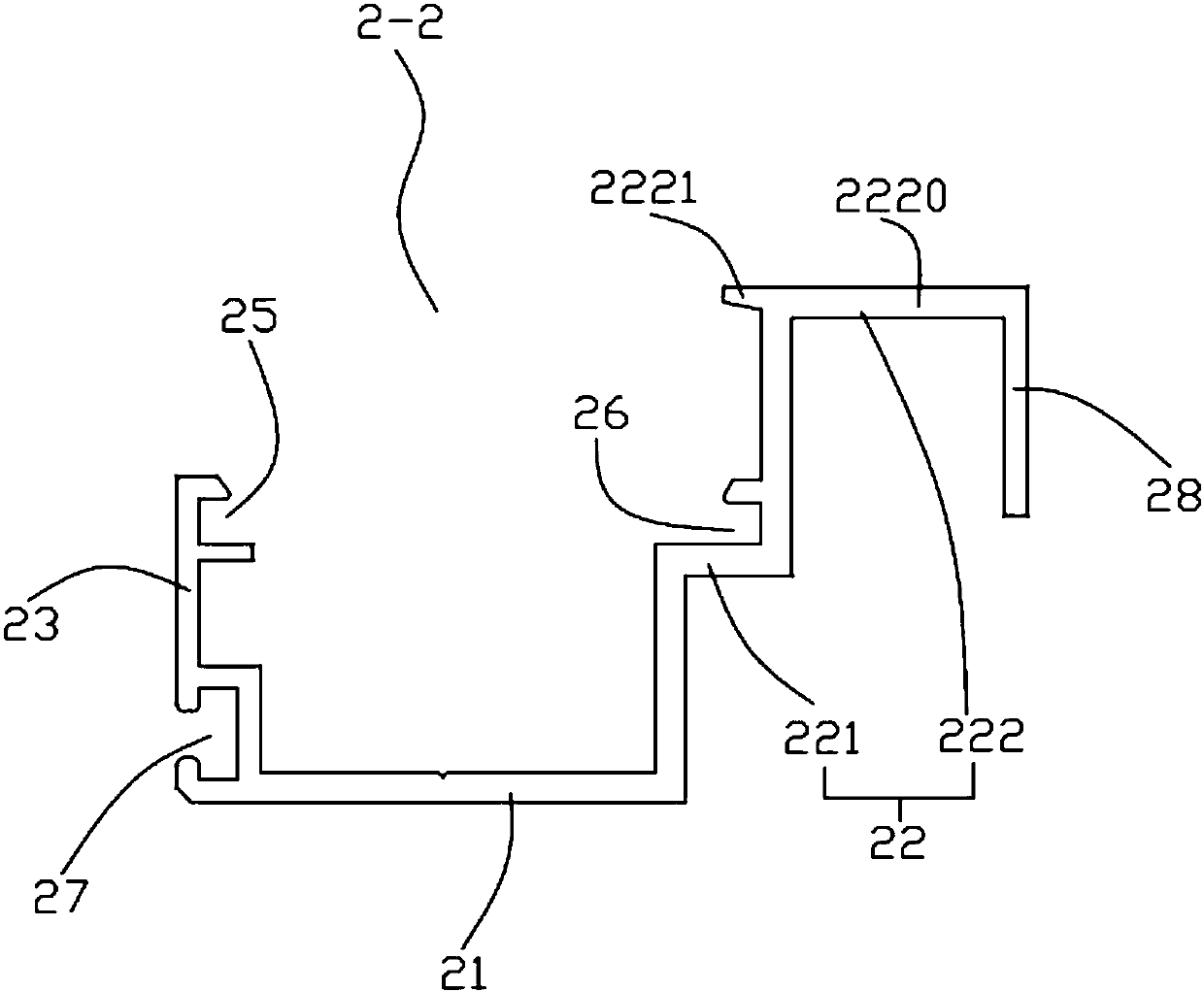

[0034] Such as figure 2 , Figure 4-Figure 7 , the embodiment of the present invention provides a curtain wall base plate 2-1, including a mounting section 21 for fastening with the corresponding curtain wall support frame member through a second threaded fastener 72 and for connecting with the adjacent curtain wall panel 6. The packaging section 22 that is tightly pressed against the surface, the packaging section 22 is butted with the corresponding end of the installation section 21, the board surface of the installation section 21 is perpendicular to the abutting surface of the packaging section 22, and the installation section 21 A fastener passing hole adapted to the second threaded fastener 72 is opened on the top. The curtain wall base plate 2-1 provided in this embodiment is fixedly connected to the indoor curtain wall support frame member through the installation section 21, and the encapsulation section 22 directly abuts against the curtain wall panel 6, that is, t...

Embodiment 3

[0046] Such as Figure 4 and Figure 5 , the embodiment of the present invention provides a reinforced connection assembly for curtain wall, which is used to connect two adjacent curtain wall panels 6 in the curtain wall. The curtain wall briquetting block 1 provided in Example 1 and the two bottom plates 2 are preferably the curtain wall briquette 2-1 provided in the above-mentioned embodiment 2, and the specific structures of the briquetting block 1 and the bottom plate 2-1 are not repeated here.

[0047] The pressing plate 11 of the pressing block 1 is pressed against the outer surfaces of the two adjacent curtain wall panels 6, and the installation section 21 of each base plate 2 is fixedly connected to the corresponding side of the corresponding curtain wall supporting frame member, and the encapsulating section 22 is connected to the corresponding side of the curtain wall panel. The inner surface of the board 6 is pressed tightly, and a slot for inserting the curtain wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com