Fixing structure of plastic mould

A fixed structure and plastic mold technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of the use of fixed structures, reduce the accuracy of processing, and the fixed structure cannot be processed by mold size adjustment, etc., to achieve good fixing effect, Efficient and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them.

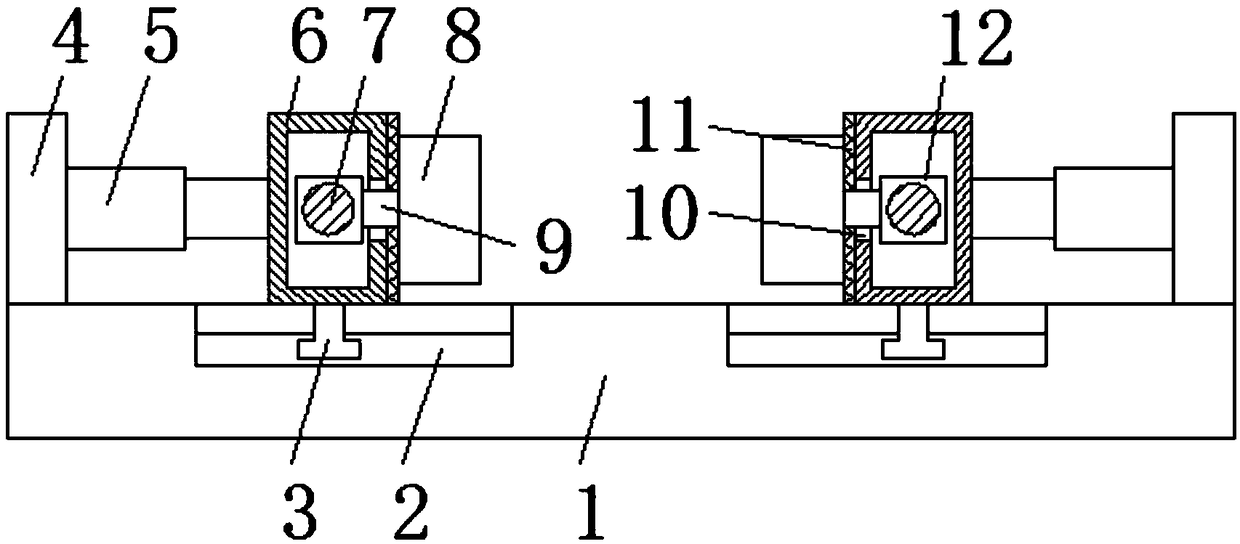

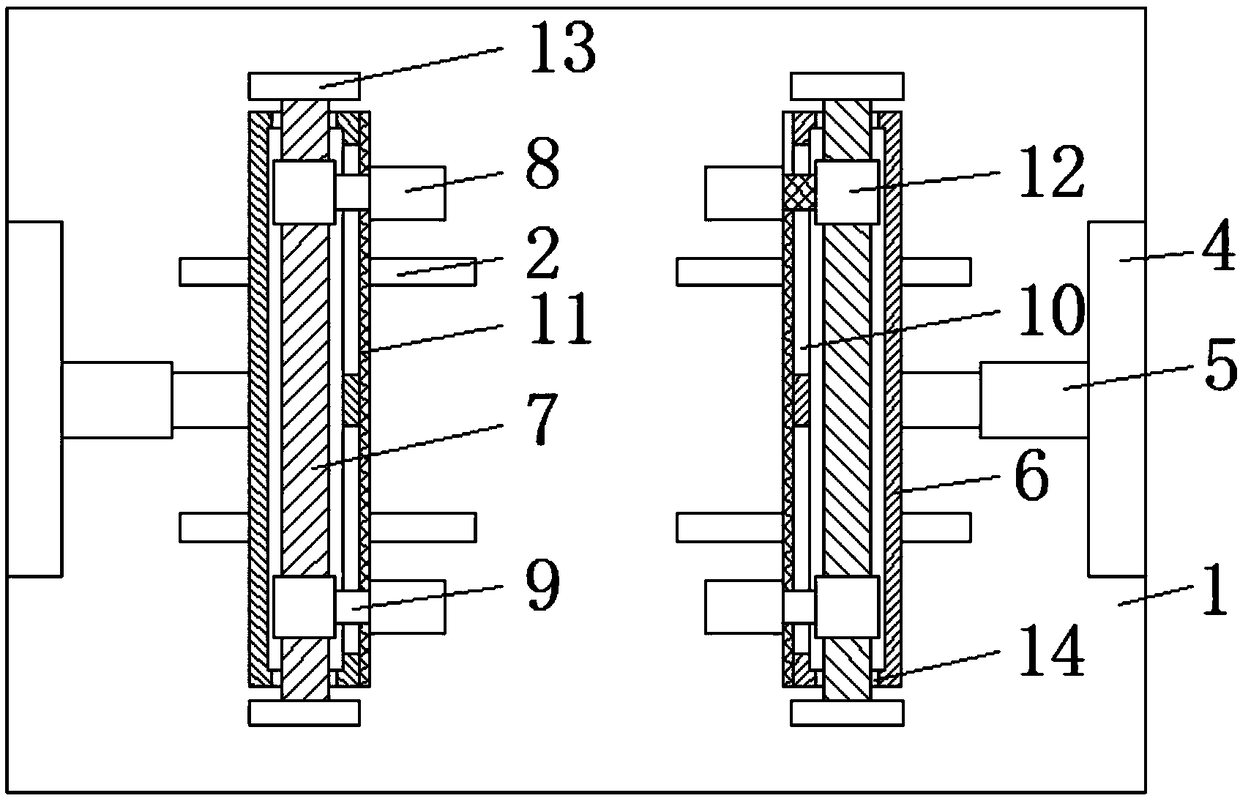

[0015] refer to Figure 1-2 , a fixed structure of a plastic mold, including a base 1, a support plate 4 is fixed at the center of both sides of the upper end of the base 1, a hydraulic telescopic rod 5 is installed at the center of the corresponding side of the two support plates 4, and two hydraulic telescopic The output shaft of the rod 5 is connected with an extrusion box 6, and the two extrusion boxes 6 are limited by a sliding mechanism. When the plastic mold is fixed, the plastic mold is first placed on the base 1 between the two extrusion boxes 6 On the top, the hydraulic telescopic rod 5 is connected to the external power supply through a wire, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com