Assembly line grabbing mechanical arm

A mechanical arm and assembly line technology, applied in the directions of manipulators, manufacturing tools, chucks, etc., can solve the problems of falling ceramic workpieces with clamping force, unfavorable glaze sealing operation, and difficulty in grasping clamping force, and achieve the effect of speeding up the curing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

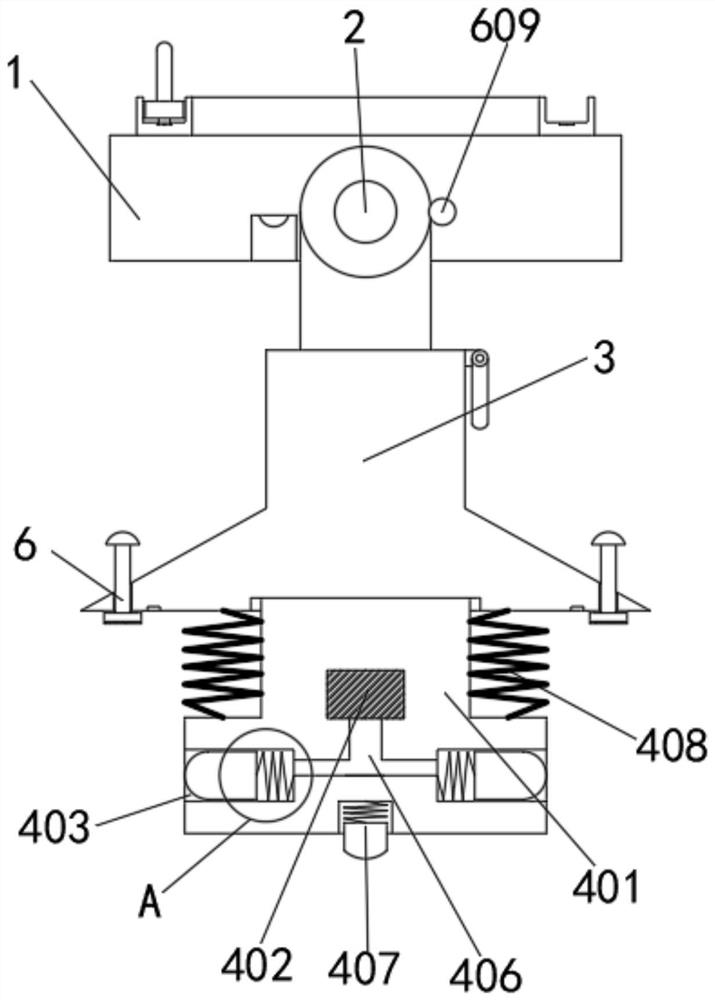

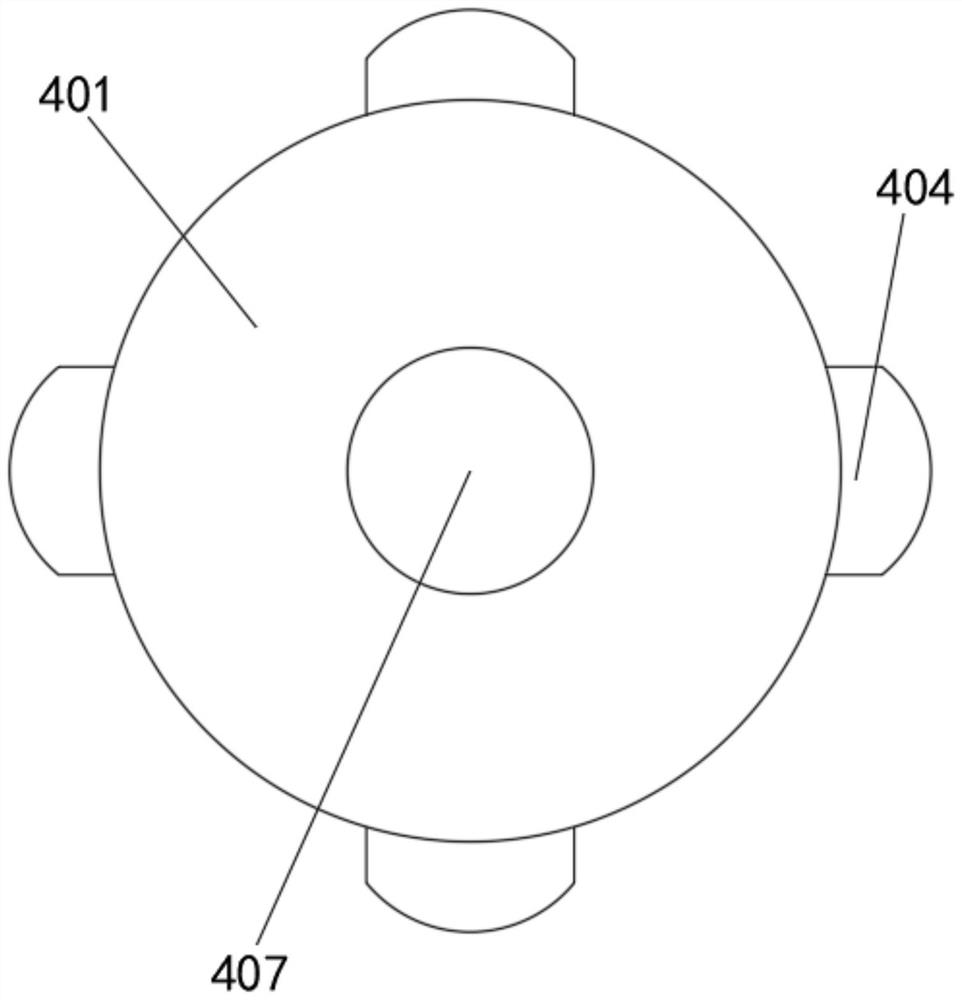

[0032] see figure 1 - Figure 4, an assembly line grabbing mechanical arm, including a fixed block 1, a rotating assembly 2 is movably installed in the middle of the fixed block 1, and a mounting platform 3 is movably socketed on the lower end of the rotating assembly 2, and an internal clamping device is movably installed at the lower end of the mounting platform 3 Mechanism 4, a ceramic workpiece 5 is detachably installed on the outside of the internal clamping mechanism 4, a curing auxiliary mechanism 6 is movably installed on the upper end of the fixed block 1, a sealing glaze pool 7 is arranged on the outside of the ceramic workpiece 5, and the rotating assembly 2 includes a rotating round block 201 , the lower end of the rotating round block 201 is fixedly installed with an installation column 202, the rotating round block 201 is movably installed in the middle of the fixed block 1, and the upper end of the installation column 202 is fixedly connected with the rotating r...

Embodiment 2

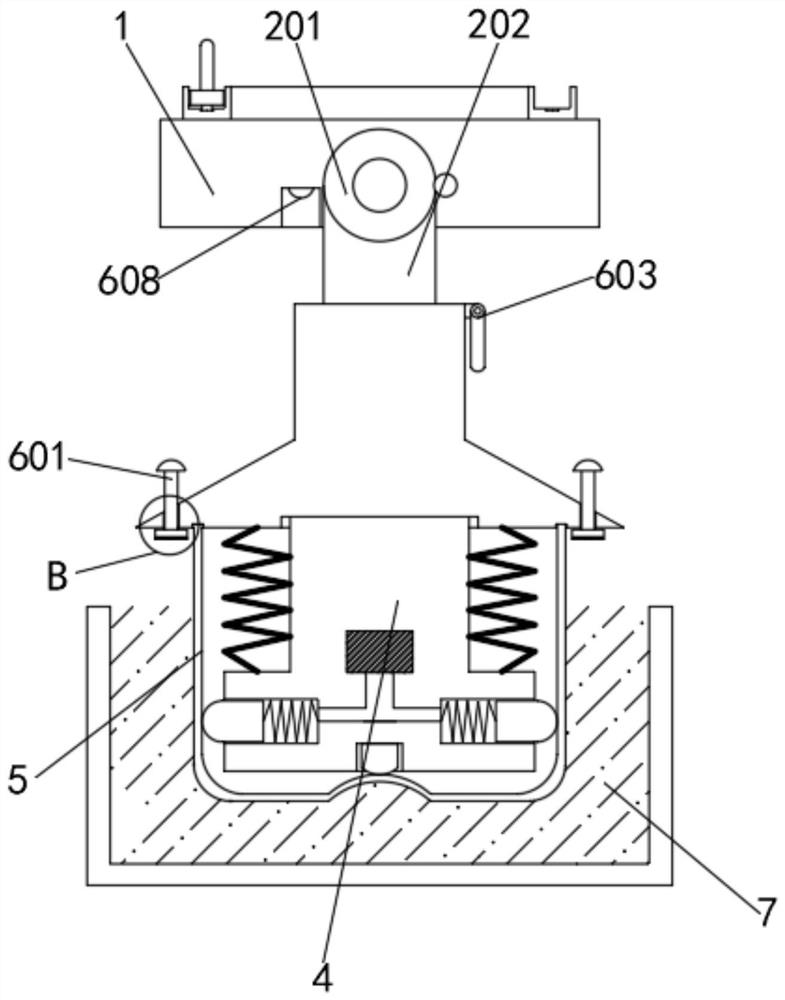

[0040] see Figure 5 - Figure 8 , an assembly line grabbing mechanical arm, including a fixed block 1, a rotating assembly 2 is movably installed in the middle of the fixed block 1, and a mounting platform 3 is movably socketed on the lower end of the rotating assembly 2, and an internal clamping device is movably installed at the lower end of the mounting platform 3 Mechanism 4, the ceramic workpiece 5 is detachably installed on the outside of the internal clamping mechanism 4, the upper end of the fixed block 1 is movably installed with a curing auxiliary mechanism 6, the rotating assembly 2 includes a rotating round block 201, and the lower end of the rotating round block 201 is fixedly installed with an installation The column 202 and the rotating round block 201 are movably installed in the middle of the fixed block 1, and the upper end of the installing column 202 is fixedly connected with the rotating round block 201, so that when the rotating round block 201 rotates, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com