Landscaping landscape assembling equipment

An assembly equipment and landscaping technology, which is applied in the field of landscaping and landscape, can solve the problems that the upper and lower glass plates cannot be well aligned, affecting the accuracy of assembly, etc., and achieve accurate and reliable assembly alignment, accurate and reliable assembly, and good flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

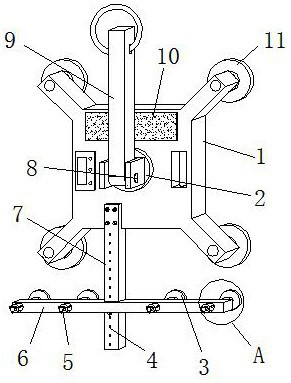

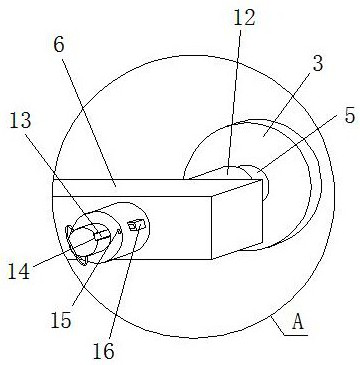

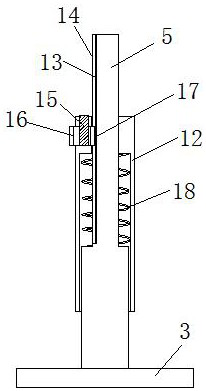

[0024] see Figure 1 to Figure 4 , the present invention provides a technical solution: an assembly equipment for landscaping and landscaping, comprising an assembly suction cup frame 1, vacuum suction cups 11 are installed at the four corners of the assembly suction cup frame 1, and the bottom of the end surface of the assembly suction cup frame 1 is fixed There is a mounting frame 7, the outer wall of the mounting frame 7 is provided with a slide frame 6, four mounting tubes 12 are fixed through the sliding frame 6, the inside of the mounting tube 12 is penetrated with an adjusting rod 5, and the designed adjusting rod 5, mounting frame 7 and the sliding frame 6, the sliding frame 6 slides up and down on the mounting frame 7 to adjust the height of the adjustment rod 5 to be aligned, and then adjust the extension length of the adjustment rod 5 in the installation cylinder 12 to realize the adjustment of the upper and lower sides. The glass plates to be assembled are aligned,...

Embodiment 2

[0028] see Figure 1 to Figure 5, the present invention provides a technical solution: an assembly equipment for landscaping and landscaping, comprising an assembly suction cup frame 1, vacuum suction cups 11 are installed at the four corners of the assembly suction cup frame 1, and the bottom of the end surface of the assembly suction cup frame 1 is fixed There is a mounting frame 7, the outer wall of the mounting frame 7 is provided with a slide frame 6, four mounting tubes 12 are fixed through the sliding frame 6, the inside of the mounting tube 12 is penetrated with an adjusting rod 5, and the designed adjusting rod 5, mounting frame 7 and the sliding frame 6, the sliding frame 6 slides up and down on the mounting frame 7 to adjust the height of the adjustment rod 5 to be aligned, and then adjust the extension length of the adjustment rod 5 in the installation cylinder 12 to realize the adjustment of the upper and lower sides. The glass plates to be assembled are aligned, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com