Structure design and construction process for preventing concrete cracks

A structural design and concrete technology, applied in building construction, building material processing, construction, etc., can solve the problems of concrete structure fracture, short protection period, time-consuming and laborious, etc. The effect of improving followability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

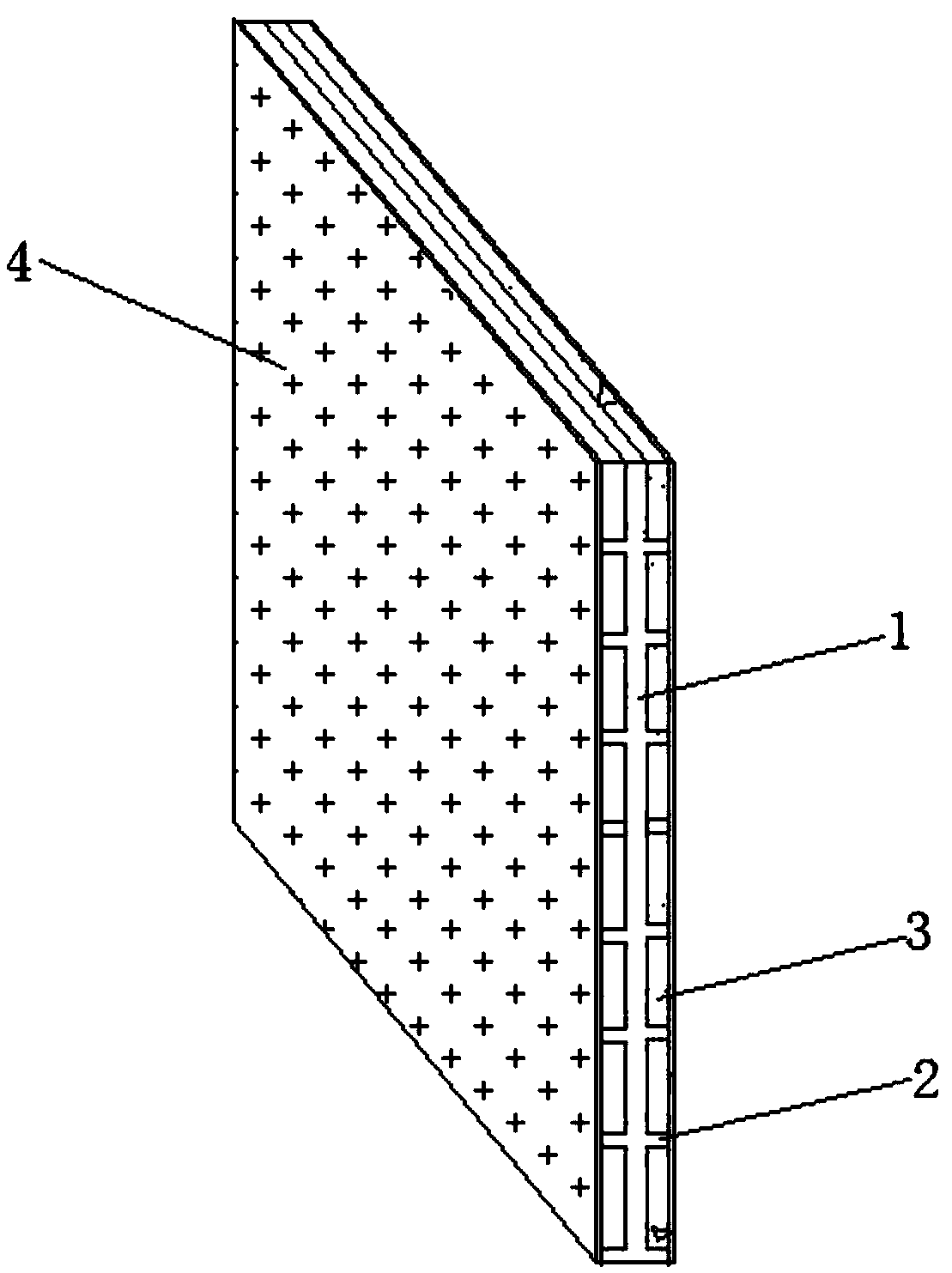

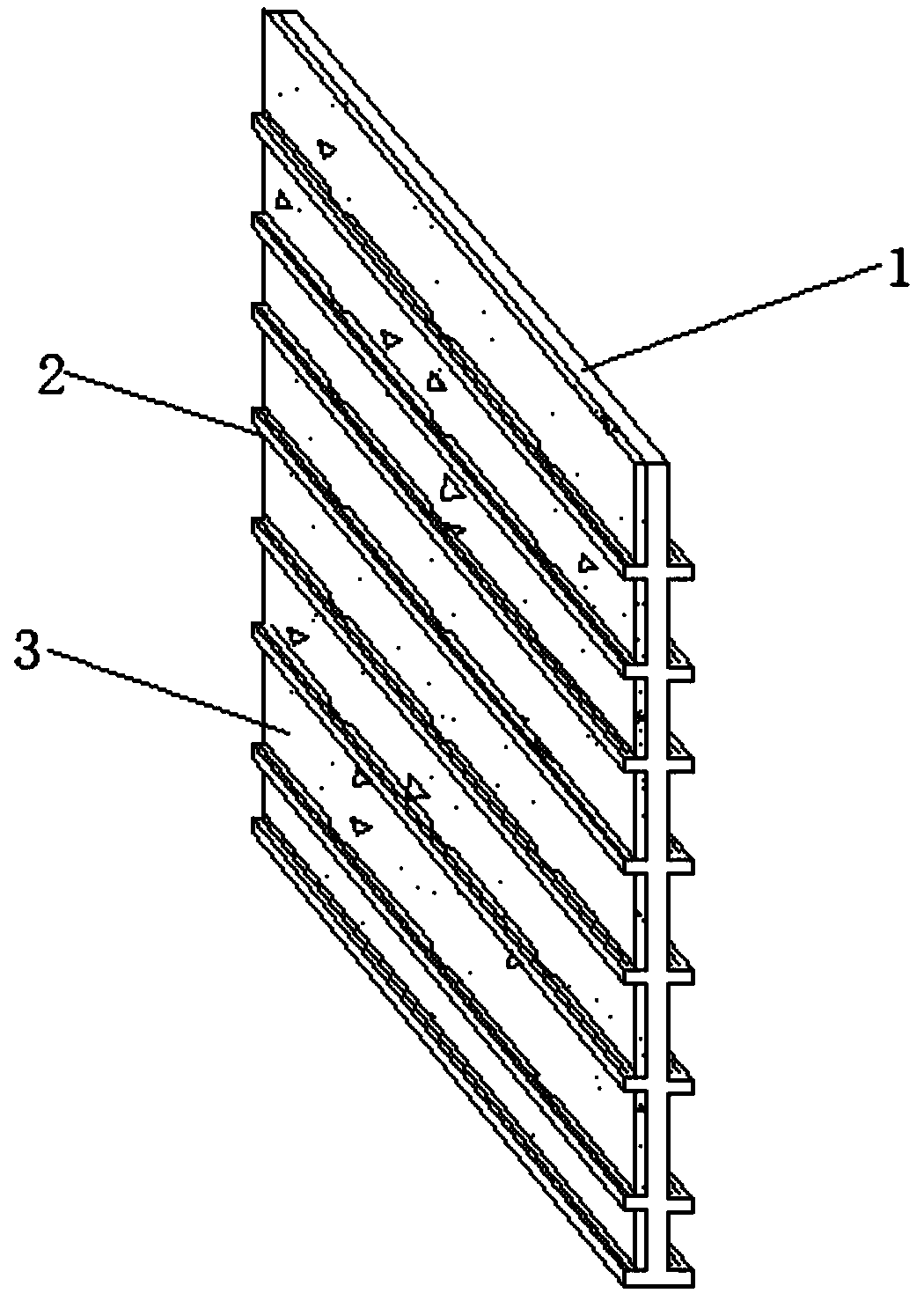

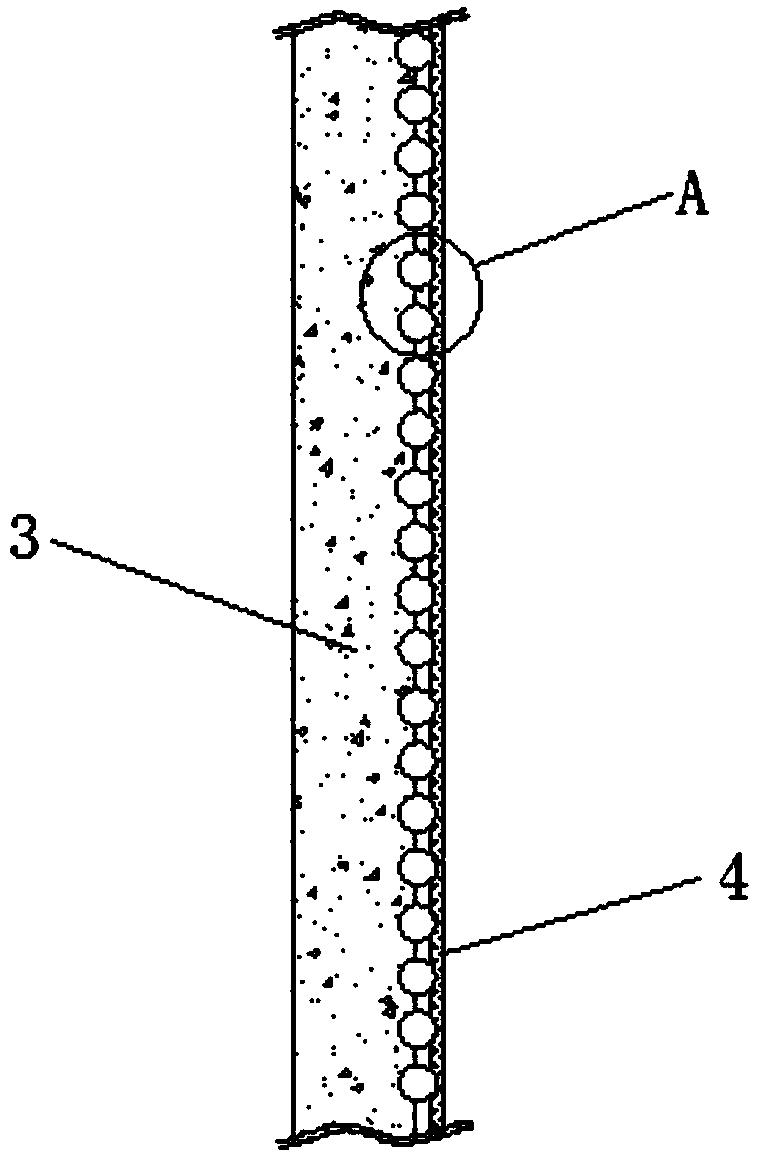

[0049] see figure 2 , a structural design for preventing concrete cracks, including concrete 3 embedded with a pre-embedded support plate 1 inside, and a plurality of auxiliary support plates 2 connected to the side ends of the embedded support plate 1, and the plurality of auxiliary support plates 2 are formed from above And the bottom is evenly arranged on the pre-embedded support plate 1, the auxiliary support plate 2 can play a load-bearing role, and reduce the self-bearing weight of the concrete slurry. Funnel-shaped through holes, multiple half-funnel-shaped through-holes are evenly arranged on the auxiliary support plate 2, and the concrete slurry penetrates into the half-funnel-shaped through-holes, which can enhance the adhesion of the concrete slurry and prevent it from falling off due to cracking. Please refer to figure 1 , image 3 and Figure 4 , the surface of the concrete 3 is laid with a layer of telescopic flow distribution net, and a plurality of dual-purp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com