Hydraulic intelligent well completion system

An intelligent well completion and hydraulic technology, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of cable control reliability and downhole life instability, and achieve reliability and service life problem, minimization of interval control, and the effect of solving the limitation on the number of intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further technically described below with reference to the accompanying drawings and embodiments.

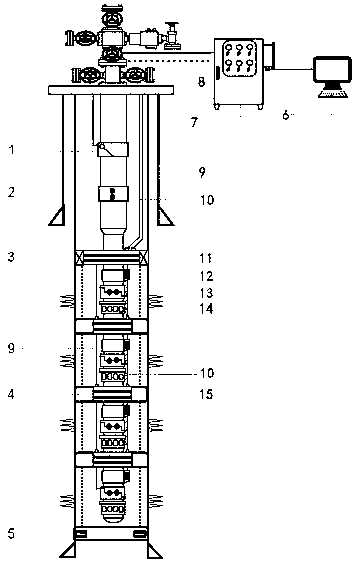

[0023] Such as figure 1 As shown, a hydraulic intelligent well completion system, in which the wellhead is provided with a penetrating sealer; the system includes downhole tools, pipelines and cables, and a ground control system 7; the upper part of the downhole tool is provided with a downhole Safety valve 1 and circulating sliding sleeve 2; the lower part of the downhole tool is a multi-layer structure, and each layer includes a multi-stage flow control valve 14, a decoder 13, a detector 12, and an isolation seal assembly 15. Each layer The top and bottom of the section are provided with packers; the pipeline cables include hydraulic control pipelines 9 and armored data cables 10; the multi-stage flow control valve 14 is controlled by two hydraulic control pipelines 9 Metal-sealed sliding sleeve system, each gear of the multi-stage flow con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com