Apparatus for additevely manufacturing three-dimensional objects

A technology of equipment and gas flow, applied in the direction of additive manufacturing, processing manufacturing, metal processing equipment, etc., can solve the problems of gas flow influence, quality influence of additive construction process, etc., and achieve the effect of improving flow characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

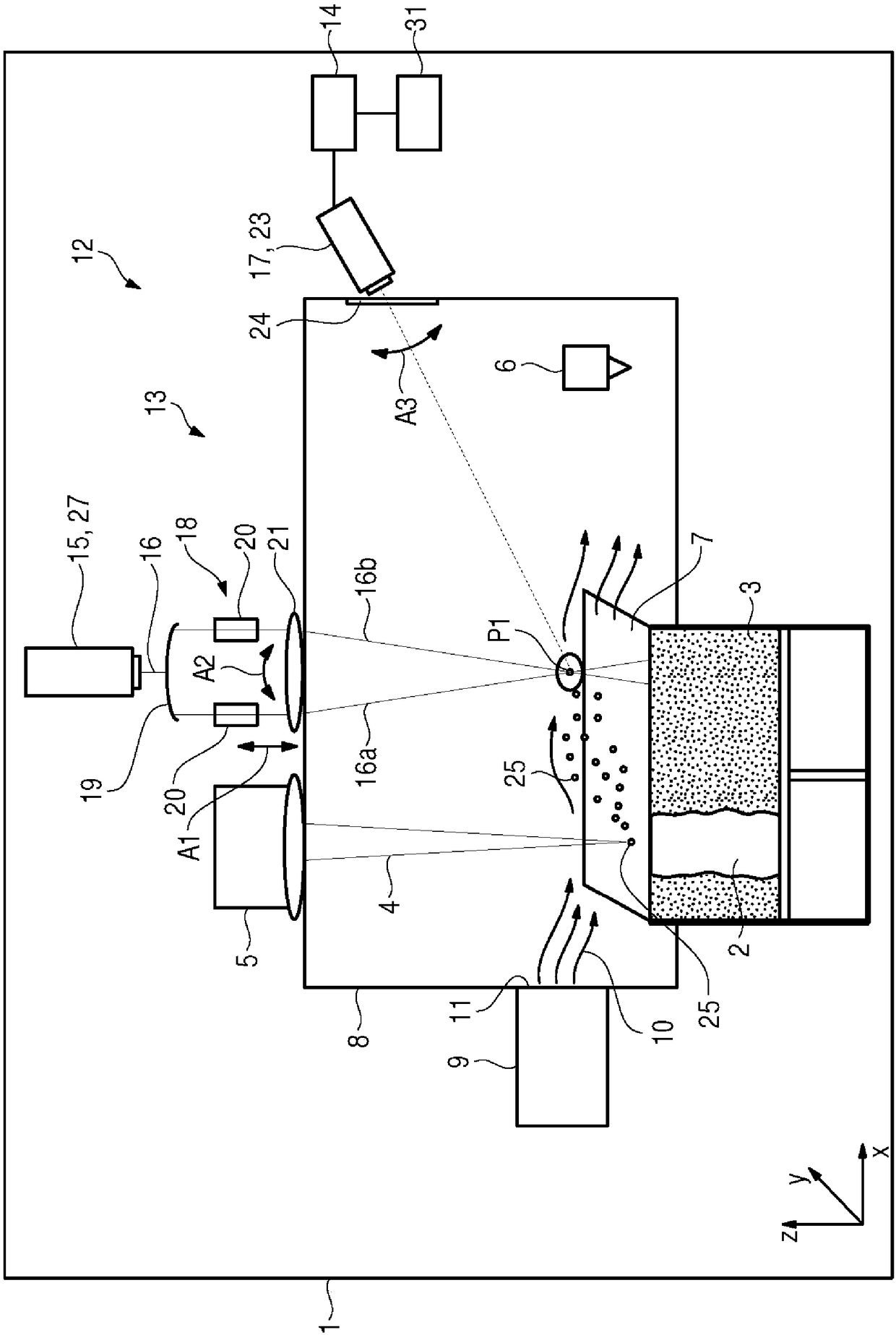

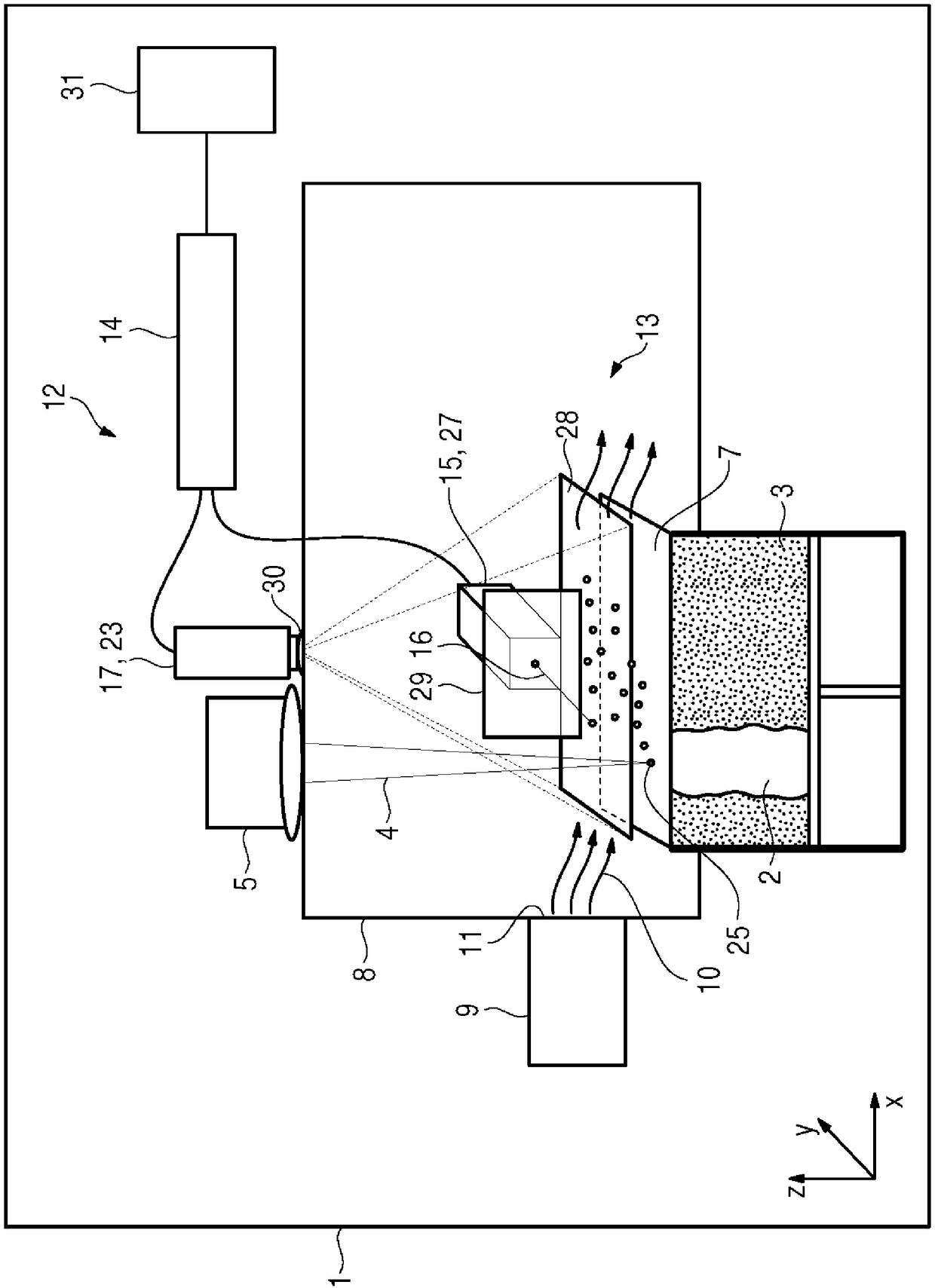

[0038] figure 1 , 2 In each case a schematic diagram of a device 1 is shown for a powdery construction material 3 ( Three-dimensional objects 2, such as technical components, are additively manufactured from layers of metal powder, for example. The device 1 can be, for example, a selective laser melting device or a selective electron beam melting device.

[0039] The device 1 comprises a plurality of structural and / or functional units.

[0040] An exemplary functional unit is an irradiation device 5 , in particular an energy beam generating device and / or an energy beam deflecting device, such as a scanning device, for selectively irradiating the build material layer with at least one energy beam 4 .

[0041] A further exemplary functional unit is a build material application device 6 , in particular a coating device, for applying a layer of build material 3 onto the build plane 7 of eg the process chamber 8 of the device 1 .

[0042] Another exemplary functional unit is a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap